Solid metal magnesium alloy core-spun yarn for steelmaking desulfuration and manufacture method of solid metal magnesium alloy core-spun yarn

A technology of metal magnesium and alloy cladding, applied in the field of metallurgy, can solve the problems of short contact time between magnesium and molten steel, large amount of magnesium vaporization, and reduced amount of magnesium, so as to shorten the processing time of magnesium, reduce the cost of magnesium processing, and reduce the process temperature. drop effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

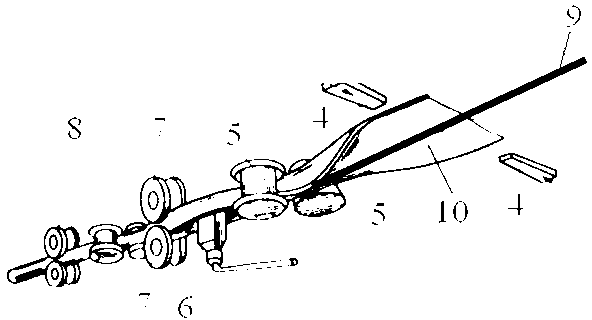

[0021] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

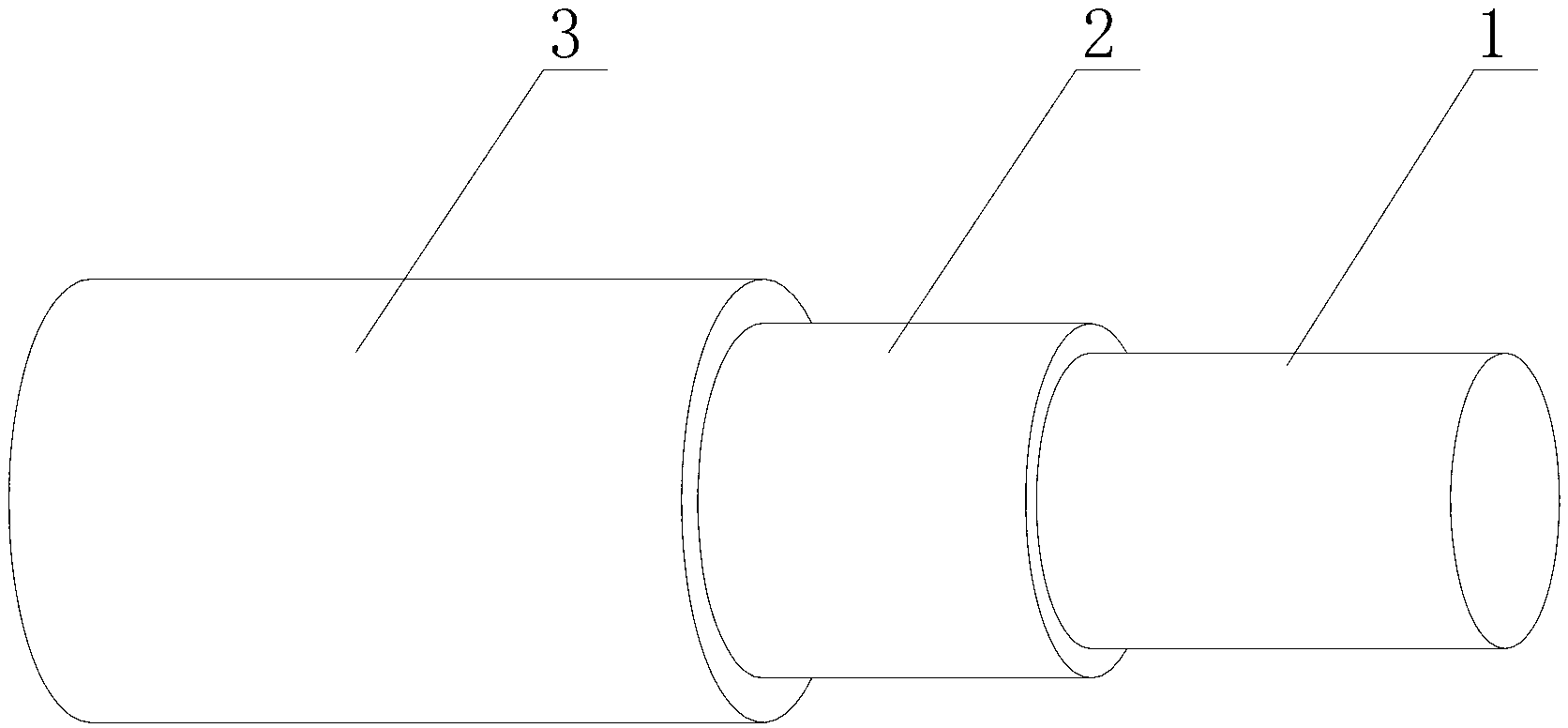

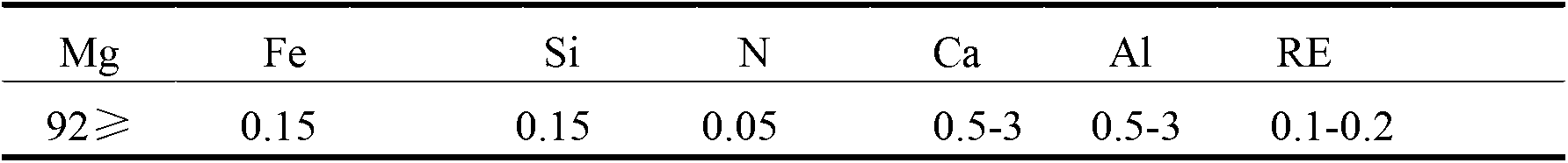

[0022] figure 1 Shown is the solid metal magnesium alloy cored wire used for steelmaking desulfurization according to the present invention, including an outer steel pipe, a middle passivation layer and an inner core, and the inner core is a solid metal magnesium alloy wire whose total weight of impurities is ≤0.2wt%. . The composition of the solid metal magnesium alloy wire includes: 93.6wt% magnesium, 3wt% aluminum, 3wt% calcium, 0.2wt% rare earth, 0.2wt% impurities, and the alloy density is 1.73g / cm 3 . The intermediate passivation layer is an oxalic acid passivation film, and the outer steel pipe is an 08A welded pipe. The welded pipe has a diameter of 8-12mm and a thickness of 0.5-1.0mm.

[0023] The diameter of the inner core is 6-8mm; its manufacturing process is: magnesium alloy batch smelting-heat treatment-heating-extrusion-oxa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com