Preparation method for antibacterial nano-silver composite nanofiber mat by electrostatic spinning

A technology of composite nanofiber and electrospinning method, which is applied in fiber processing, textile and papermaking, filament/thread forming, etc. It can solve the problems of difficult to achieve antibacterial effect and complicated preparation process of nano silver, and achieve low price and low cost. Low, strong antibacterial effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

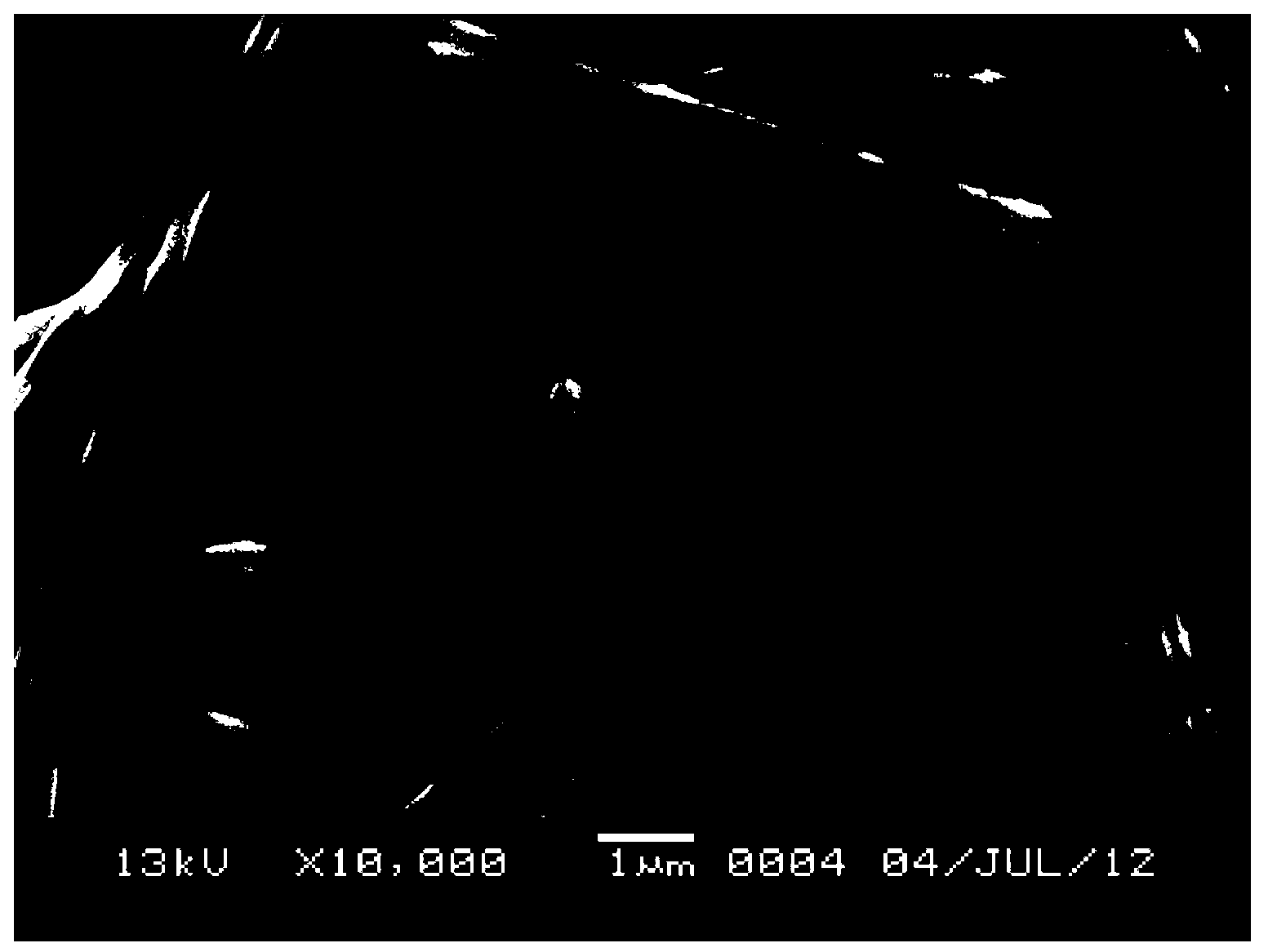

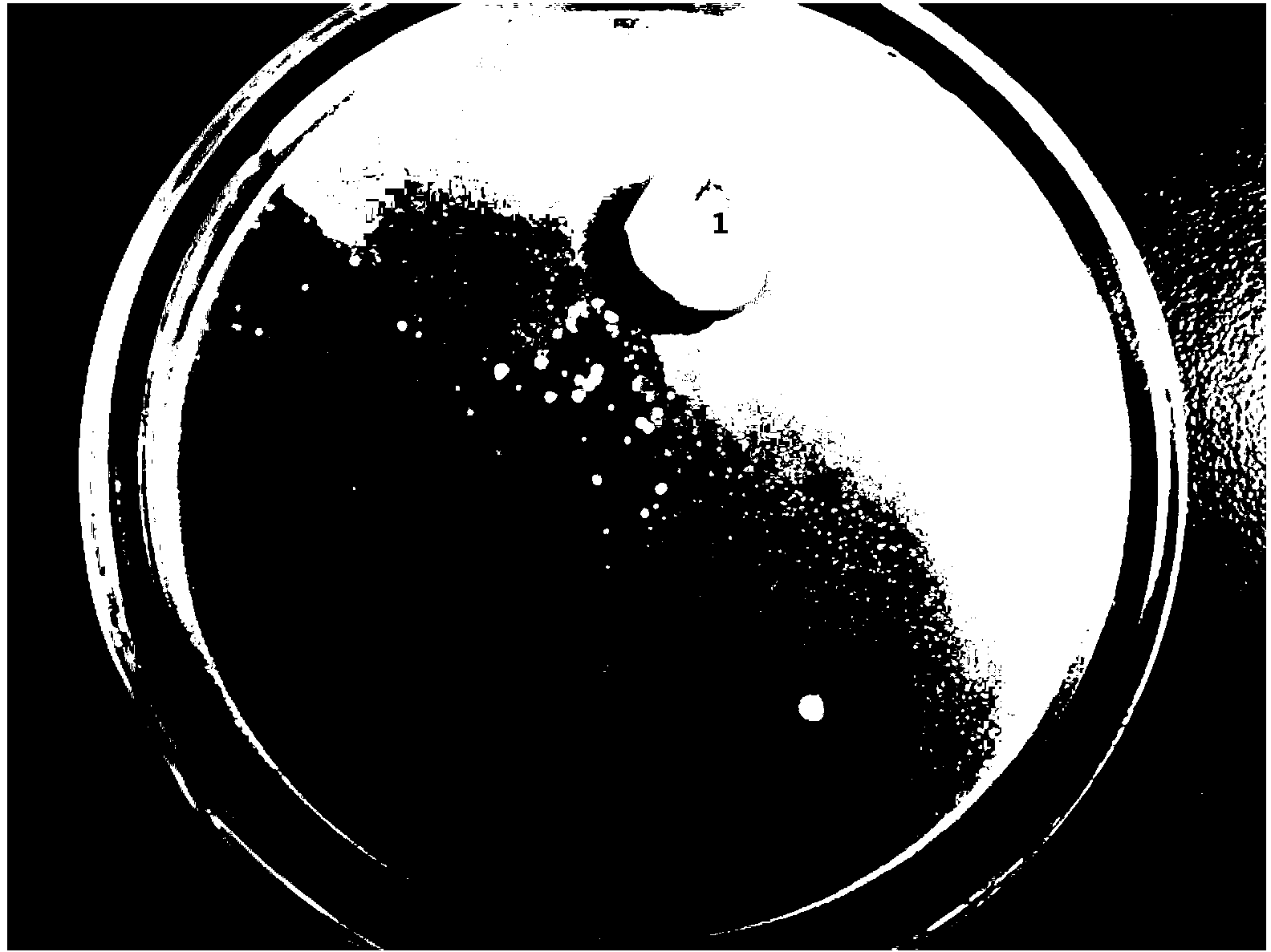

Image

Examples

Embodiment 1

[0035] Dissolve 0.1 g of PVPK90 white solid powder in 1 mL of water, in a silver nitrate solution with a concentration of 0.5 mol / L, magnetically stir for 1 h, and ultrasonically degas for 2 min.

[0036] The obtained solution was protected from microwaves for 1 min and stopped for 1 min for three consecutive times. After cooling down, 0.5 mL / h of alcohol was added and stirred continuously for 2 h to obtain a shell solution.

[0037] Dissolve 0.1 g of PVPK90 white solid powder and 0.02 g of ferulic acid in 1 mL of acetone, magnetically stir for 4 h, and ultrasonically degas for 5 min.

[0038] Put the former two under different propulsion pumps, and electrospin in a closed environment with a temperature of 20°C and a humidity of 25%. The specific conditions of spinning are: voltage 5kv, shell flow rate 3mL / h, core flow rate 0.5mL / h h, the receiving distance between the needle and the aluminum foil is 5cm.

[0039] Place the obtained drug-loaded nano-silver fiber mat in a vacu...

Embodiment 2

[0041] Dissolve 0.1 g of PVPK90 white solid powder in 1 mL of silver nitrate solution with a concentration of 1 mol / L, stir magnetically for 4 h, and degas by ultrasonication for 5 min.

[0042] The obtained solution was protected against microwaves for 2 minutes, stopped for 1 minute, and continued for three times. After cooling down to room temperature, 0.25 mL of alcohol was added and stirred continuously for 2 hours to obtain a shell solution.

[0043] Dissolve 0.1 g of polylactic acid and 0.02 g of ferulic acid in 1 mL of ethanol, stir for 4 h with magnetic force, and degas with ultrasonic for 5 min.

[0044] Put the former two under different propulsion pumps, and electrospin in a closed environment with a temperature of 25°C and a humidity of 50%. The specific conditions of spinning are: voltage 10kv, shell flow rate 1mL / h, core flow rate 1mL / h , the receiving distance between the needle and the aluminum foil is 15cm.

[0045] Place the obtained drug-loaded nano-silver...

Embodiment 3

[0047] Dissolve 0.08 g of PVPK90 white solid powder in 1 mL of silver nitrate solution with a concentration of 2 mol / L, magnetically stir for 10 h, and ultrasonically degas for 10 min.

[0048] The obtained solution was protected from microwaves for 3 minutes, stopped for 1 minute, and continued for three times. After cooling down, 0.02 g of PVP powder was added and stirred continuously for 2 hours to obtain a shell solution.

[0049] Dissolve 0.1 g of polylactic-glycolic acid and 0.02 g of ferulic acid in 1 mL of dichloromethane, magnetically stir for 4 h, and ultrasonically degas for 5 min.

[0050] Put the former two under different propulsion pumps, and electrospin in a closed environment with a temperature of 35°C and a humidity of 75%. The specific conditions of spinning are: voltage 15kv, shell flow rate 0.2mL / h, core flow rate 3mL / h h, the receiving distance between the needle and the aluminum foil is 25cm.

[0051] Place the obtained drug-loaded nano-silver fiber mat i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com