Cleansing composition

A technology for compositions and cleaning agents, applied in the directions of anionic surface active compounds, preparations for skin care, detergents in bar/sheet form, etc. Good rinsing, reducing red marks and pimples

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

manufacture example 1

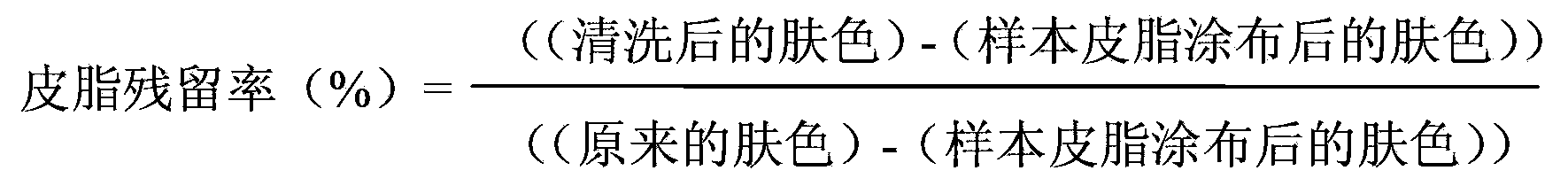

[0101] 1144g (6.14mol) of lauryl alcohol [trade name: KALCOL2098, manufactured by Kao] and 60.2g (0.281mol) of myristyl alcohol [trade name: KALCOL4098, manufactured by Kao] were added to a stainless steel autoclave equipped with stirring and temperature adjustment functions. , 2.68g (0.0478mol) of potassium hydroxide, dehydration under reduced pressure. Next, 996 g (22.6 mol) of ethylene oxide (EO) was introduced at 155° C., and the reaction was performed at a reaction temperature of 155° C. and a reaction pressure of 0.4 MPa for 2 hours. After the reaction, stir for 30 minutes at 80°C and 6kPa under reduced pressure, remove unreacted ethylene oxide, introduce nitrogen to normal pressure, and add 4.82g (0.0482mol) of 90% lactic acid into the autoclave , and stirred at 80° C. for 30 minutes to obtain an alkyl ethoxylate having an added mole number of EO of 3.55 mol (hereinafter referred to as “produced AE”).

[0102] 90g (0.2mol) of the above product, 16.7g of 48% sodium hydr...

manufacture example 2

[0109] Following Production Example 1, EO was mixed with decyl alcohol [trade name: KALCOL1098, manufactured by Kao], lauryl alcohol [trade name: KALCOL2098, manufactured by Kao], myristyl alcohol [trade name] at a mass ratio of 10 / 70 / 15 / 5. : KALCOL4098, manufactured by Kao] and cetyl alcohol [trade name: KALCOL6098, manufactured by Kao] were reacted to obtain an alkyl ethoxylate having an added mole number of EO of 3.55 mol. This was subjected to an oxidation reaction in the same manner as in Example 1, and an alkyl ether carboxylic acid was obtained by treating the obtained alkyl ether carboxylate with hydrochloric acid. Make it EC2.

[0110] The analysis result of gas chromatography obtained by analytical method 1, EC2 is in the general formula (1), M=H, R 1 It is decyl / lauryl / myristyl / palmityl=10 / 70 / 15 / 5, the average number of carbon atoms is 12.3, the average value of n is 3.1, n=0 contains 16% by mass, and n=1 The total amount of the components and n=2 components was 3...

manufacture example 3

[0114] Following Production Example 1, decyl alcohol was used as a raw material to react with EO to obtain an alkyl ethoxylate with 3.55 moles of EO added. This was subjected to an oxidation reaction in the same manner as in Example 1, and the obtained alkyl ether carboxylate was treated with hydrochloric acid to obtain an alkyl ether carboxylic acid.

[0115] The analysis result of gas chromatography obtained by analytical method 1 is that, in the general formula (1), M=H, R 1 It is decyl, the average value of n is 3.1, the component with n=0 contains 16% by mass, the total amount of components with n=1 and n=2 is 33% by mass, and the total amount of components with n≧6 is 18% quality%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com