Catalyst for synthesizing 2,6-xylenol as well as preparation method of catalyst and method for synthesizing 2,6-xylenol

A technology of dimethylphenol and catalyst is applied in the field of catalyst for synthesizing 2,6-dimethylphenol and its preparation and synthesizing 2,6-dimethylphenol, which can solve the problem of many catalyst components and high initial reaction temperature , complex preparation and other problems, to achieve the effect of improving activity and stability, high low temperature activity, and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Weigh Fe(NO 3 ) 3 9H 2 O404g, Mg(NO 3 ) 2 ·6H 2 O12.82g and 28.80g of phosphotungstic acid were mixed and dissolved in 800mL of ethanol, and then slowly mixed with 28% 700mL of concentrated ammonia water containing 4gPEG in a co-current manner under normal temperature ultrasonic conditions, and continued to stir for 30min after the addition was completed. Then the precipitate was filtered, washed, and baked at 120°C for 6h. The obtained solid is calcined at 450°C for 8 hours, and finally the solid is ground into fine particles, and then crushed into small particles of 10-20 meshes, which is the obtained catalyst FeMg. 0.05 PW 0.01 (PW stands for phosphotungstic acid).

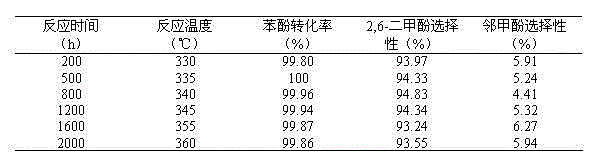

[0025] Pack 40mL of the above catalyst into a stainless steel fixed-bed reactor, the raw material is phenol:methanol:water=1:5:1 (molar ratio), and the mass space velocity is 0.4 hr -1 , the carrier gas is N 2 The flow rate is 20 mL / min, the reaction pressure is normal, and the catalyst runs st...

Embodiment 2

[0028] Weigh Fe(OAc) 3 233.05g, Mg(OAc) 2 1.42g and 94.55g of silicomolybdic acid were mixed and dissolved in 800mL of ethanol, and then slowly mixed with 700mL of 28% concentrated ammonia water containing 8gPEG in a co-current manner under ultrasonic conditions at room temperature. The precipitate was filtered, washed, and baked at 120°C for 6h. The obtained solid is calcined at 450°C for 8 hours, and finally the solid is ground into fine particles, and then crushed into small particles of 10-20 meshes, which is the obtained catalyst FeMg. 0.01 SM 0.04 (SM stands for silicomomolybdic acid).

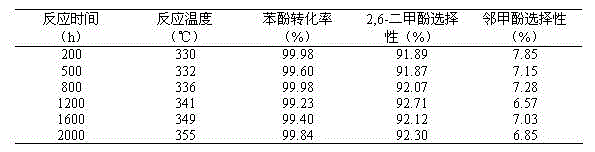

[0029] Pack 40mL of the above catalyst into a stainless steel fixed-bed reactor, the raw material is phenol:methanol:water=1:4:0.5 (molar ratio), and the mass space velocity is 0.5 hr -1 , the carrier gas is N 2 The flow rate is 15 mL / min, the reaction pressure is 0.2 MPa, and the catalyst runs stably for 2000 h in one pass. The reaction results are shown in the table below.

[00...

Embodiment 3

[0032] Weigh FeCl 3 162.21g, MgCl 2 ·6H 2 O6.10g and 37.82g of sodium phosphomolybdate were mixed and dissolved in 800mL of ethanol, and then slowly mixed with 28% 700mL of concentrated ammonia water containing 4gPEG in a co-current manner under normal temperature ultrasonic conditions, and continued to stir for 30min after the addition was complete , and then the precipitate was filtered, washed, and baked at 120°C for 6h. The obtained solid is calcined at 450°C for 8 hours, and finally the solid is ground into fine particles, and then crushed into small particles of 10-20 meshes, which is the obtained catalyst FeMg. 0.03 (PMNa) 0.02 (PMNa stands for sodium phosphomolybdate).

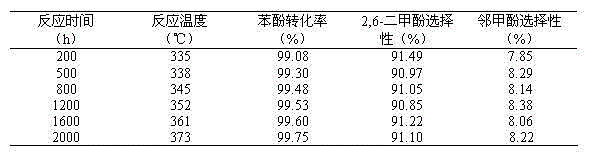

[0033] Pack 40mL of catalyst into a stainless steel fixed bed reactor, the raw material is phenol:methanol:water=1:3:0.5 (molar ratio), and the mass space velocity is 1.0 hr -1 , the carrier gas is N 2 The flow rate is 10 mL / min, the reaction pressure is 0.2MPa, and the catalyst runs stably for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com