Printing plate material for ink-jet printing direct-to-plate and preparation method of printing plate material

An inkjet printing and plate technology, which is applied in the preparation of printing surface, plate preparation, printing, etc., can solve the problems of increasing the difficulty of the plate base, dirtying, and increasing the production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

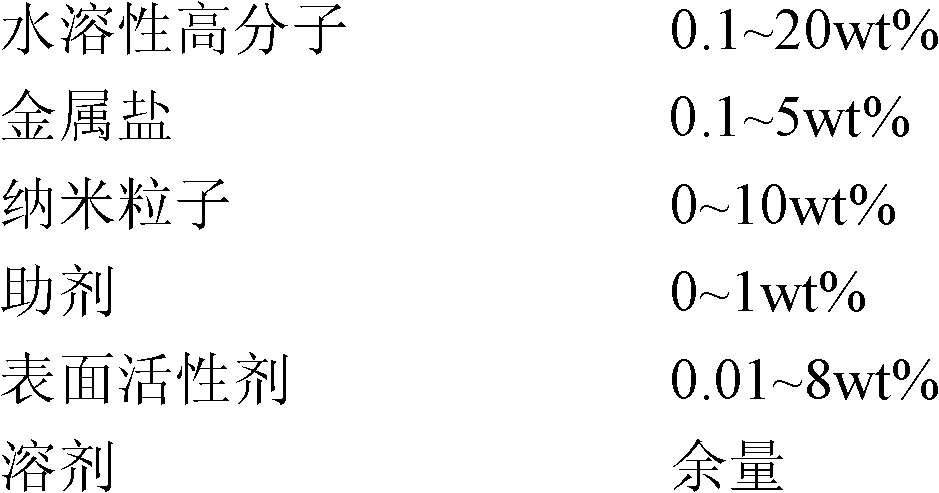

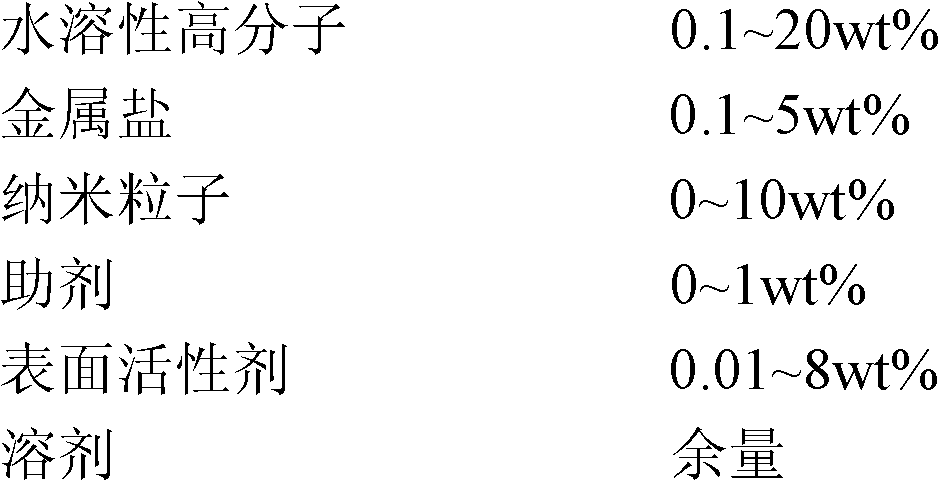

[0027] Preparation of coating: 0.1wt% gum arabic, 5wt% potassium sulfate, 10wt% zinc oxide nanoparticles with a particle size of 10nm, 0.1wt% organosiloxane, 0.2wt% propylene glycol ester and the remainder mixed with water at room temperature, stirred the mixed solution, and filtered to remove impurities to obtain a water-soluble paint.

[0028] After the electrolytic graining and anodic oxidation treatment of the aluminum base is washed and dried, the water-soluble coating obtained above is evenly coated on the surface of the aluminum base by spin coating, and dried. The thickness of the coating is about 1 μm. A plate material for inkjet printing direct-to-plate is obtained.

Embodiment 2

[0030] Preparation of coating: mix 20wt% polyethylene glycol, 0.1wt% aluminum sulfate, 0.1wt% aluminum oxide nanoparticles with a particle size of 1000nm, 20wt% water and the rest of ethanol at room temperature, and stir the mixed solution , to obtain a water-soluble paint after filtering to remove impurities.

[0031] Use 5wt% dilute sodium hydroxide aqueous solution to degrease the aluminum substrate that has not been electrolytic grained and anodized, wash and dry it with water, and apply the above-mentioned aluminum substrate evenly on the surface of the aluminum substrate by roller coating. The water-soluble paint is dried, and the thickness of the coating is about 20 μm to obtain a plate material for direct plate-making by ink-jet printing.

Embodiment 3

[0033] Preparation of coating: 10wt% polyacrylamide, 0.2wt% zinc chloride, 1wt% calcium carbonate nanoparticles with a particle size of 200nm, 0.05wt% polyether, 0.2wt% ethylene glycol ester, 0.3wt% of malic acid, 30wt% of water and the rest of ethanol are mixed at room temperature, the mixed solution is stirred, and the water-soluble paint is obtained after filtering to remove impurities.

[0034] Use 5wt% dilute sodium hydroxide aqueous solution to degrease the zinc plate base that has not undergone electrolytic graining and anodic oxidation treatment, after washing and drying, apply the above-mentioned zinc plate base evenly on the surface of the zinc plate base by spin coating to obtain The water-soluble coating is dried, and the thickness of the coating is about 5 μm, so as to obtain a plate material for direct plate making by inkjet printing.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com