Preparation method and applications of mesoporous carbon

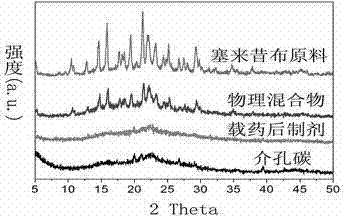

A technology of mesoporous carbon and pore size, which is applied in the field of medicine to achieve the effect of large specific surface area, simple process operation, and non-degradable physiological compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

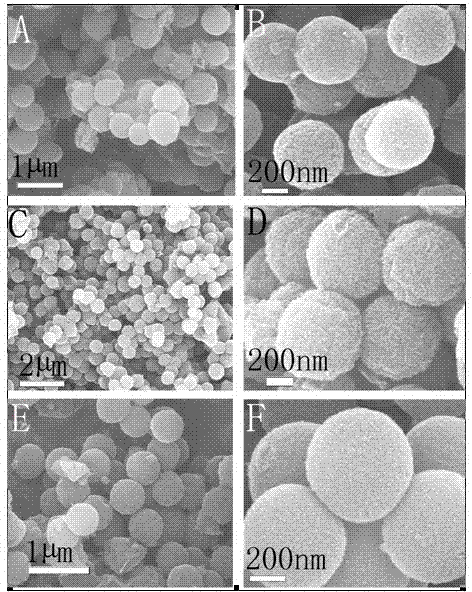

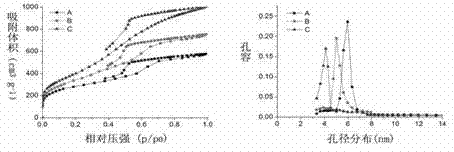

Embodiment 1

[0036] Accurately take 3g of hexadecylamine and add it to 400ml of water and isopropanol mixed solvent (volume ratio: 1:1) to dissolve it completely, add 15ml of tetraethyl orthosilicate and 3.5ml of ammonia water, stir to make the solution fully mixed and reacted , the reacted solution was subjected to high-pressure homogenization with a high-pressure homogenizer, left to stand for 16 hours, and the precipitate was collected by suction filtration or centrifugation, dried, and calcined at 600°C for 4 hours to remove the organic template to obtain a mesoporous silica template. The silica template was added to a solution containing 0.6g sucrose, 0.10ml sulfuric acid, and 4g water, mixed evenly, placed at 80°C for 6h to remove water, and then placed at 160°C for 6h for preliminary carbonization, and the product after preliminary carbonization was added to a solution containing 0.4 g sucrose, 0.08ml sulfuric acid, and 4g water were mixed evenly, placed at 80°C for 6 hours to remove...

Embodiment 2

[0038] Accurately take 4g of hexadecylamine and add it to 400ml of water and isopropanol mixed solvent (volume ratio: 1:1) to dissolve completely, add 15ml of tetraethyl orthosilicate and 3.5ml of ammonia water, stir to make the solution fully mixed and reacted , the reacted solution was subjected to high-pressure homogenization with a high-pressure homogenizer, left to stand for 16 hours, and the precipitate was collected by suction filtration or centrifugation, dried, and calcined at 600°C for 4 hours to remove the organic template to obtain a mesoporous silica template. The silica template was added to a solution containing 0.6g sucrose, 0.10ml sulfuric acid, and 4g water, mixed evenly, placed at 80°C for 6h to remove water, and then placed at 160°C for 6h for preliminary carbonization, and the product after preliminary carbonization was added to a solution containing 0.4 g sucrose, 0.08ml sulfuric acid, and 4g water were mixed evenly, placed at 80°C for 6 hours to remove mo...

Embodiment 3

[0040] Accurately take 5g of hexadecylamine and add it to 400ml of water and isopropanol mixed solvent (volume ratio: 1:1) to dissolve it completely, add 15ml of tetraethyl orthosilicate and 3.5ml of ammonia water, stir to make the solution fully mixed and reacted , the reacted solution was subjected to high-pressure homogenization with a high-pressure homogenizer, left to stand for 16 hours, and the precipitate was collected by suction filtration or centrifugation, dried, and calcined at 600°C for 4 hours to remove the organic template to obtain a mesoporous silica template. The silica template was added to a solution containing 0.6g sucrose, 0.10ml sulfuric acid, and 4g water, mixed evenly, placed at 80°C for 6h to remove water, and then placed at 160°C for 6h for preliminary carbonization, and the product after preliminary carbonization was added to a solution containing 0.4 g sucrose, 0.08ml sulfuric acid, and 4g water were mixed evenly, placed at 80°C for 6 hours to remove...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

| radius | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com