Equipment for preparing nickel oxide product from nickel chloride solution and recovering hydrochloric acid

A technology for recovering hydrochloric acid and nickel chloride, which is applied in the preparation of chloride, nickel oxide/nickel hydroxide, chlorine/hydrogen chloride, etc., can solve the problems of heavy workload, pipeline blockage, aggravated blockage, etc., and achieve the effect of reducing consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0080] The specific implementation manner of the present invention will be further described below in conjunction with the examples given in the accompanying drawings.

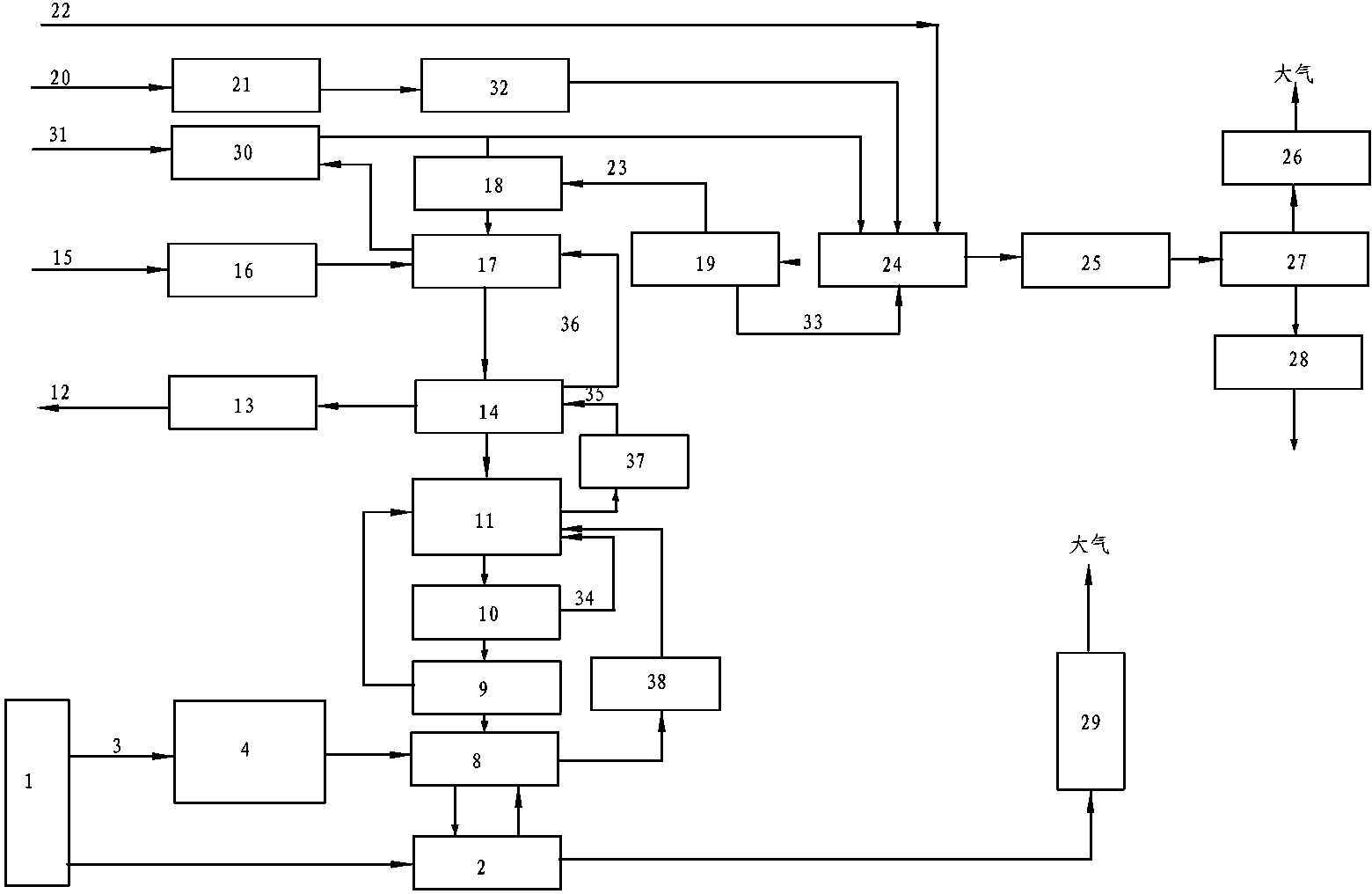

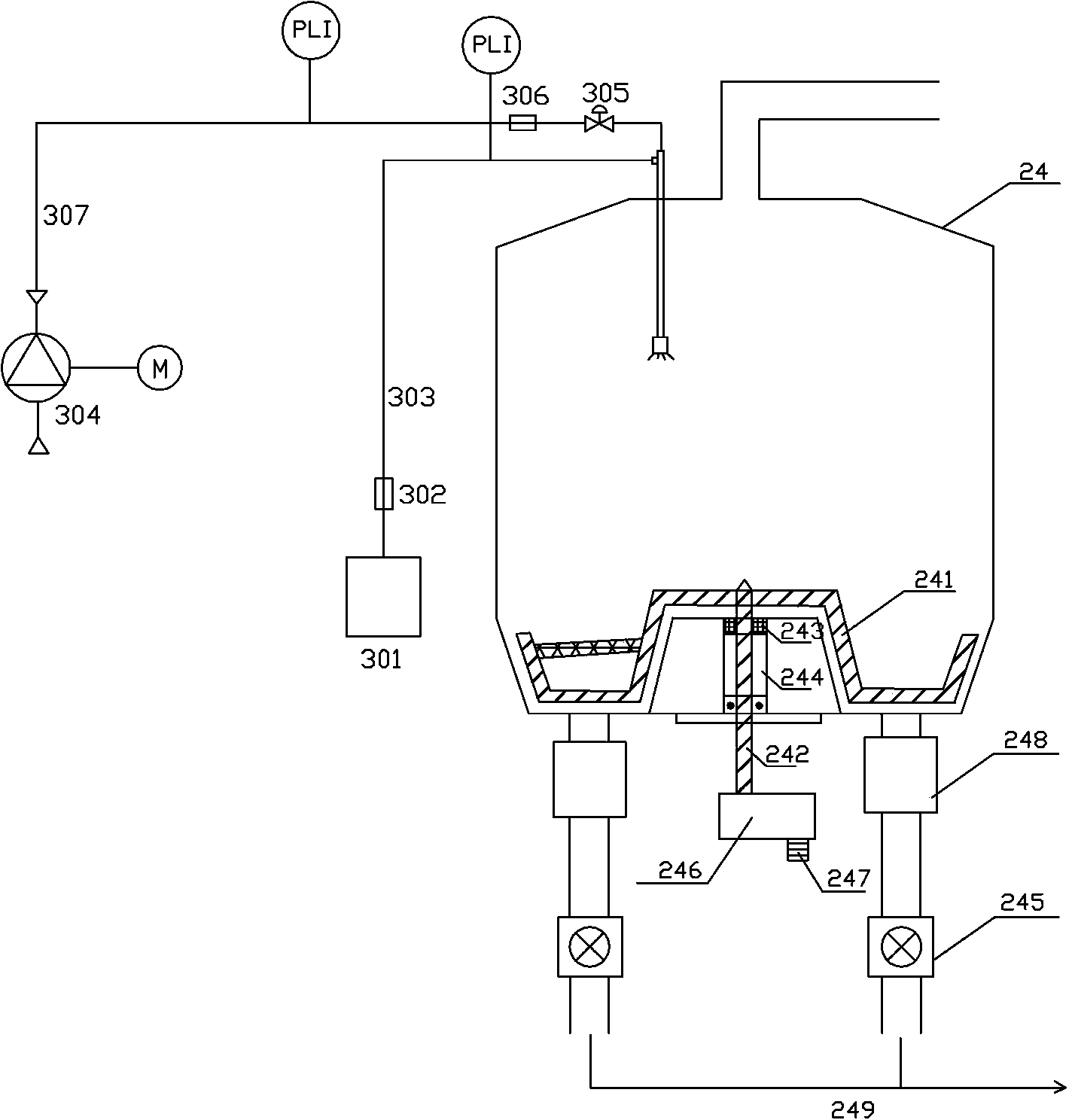

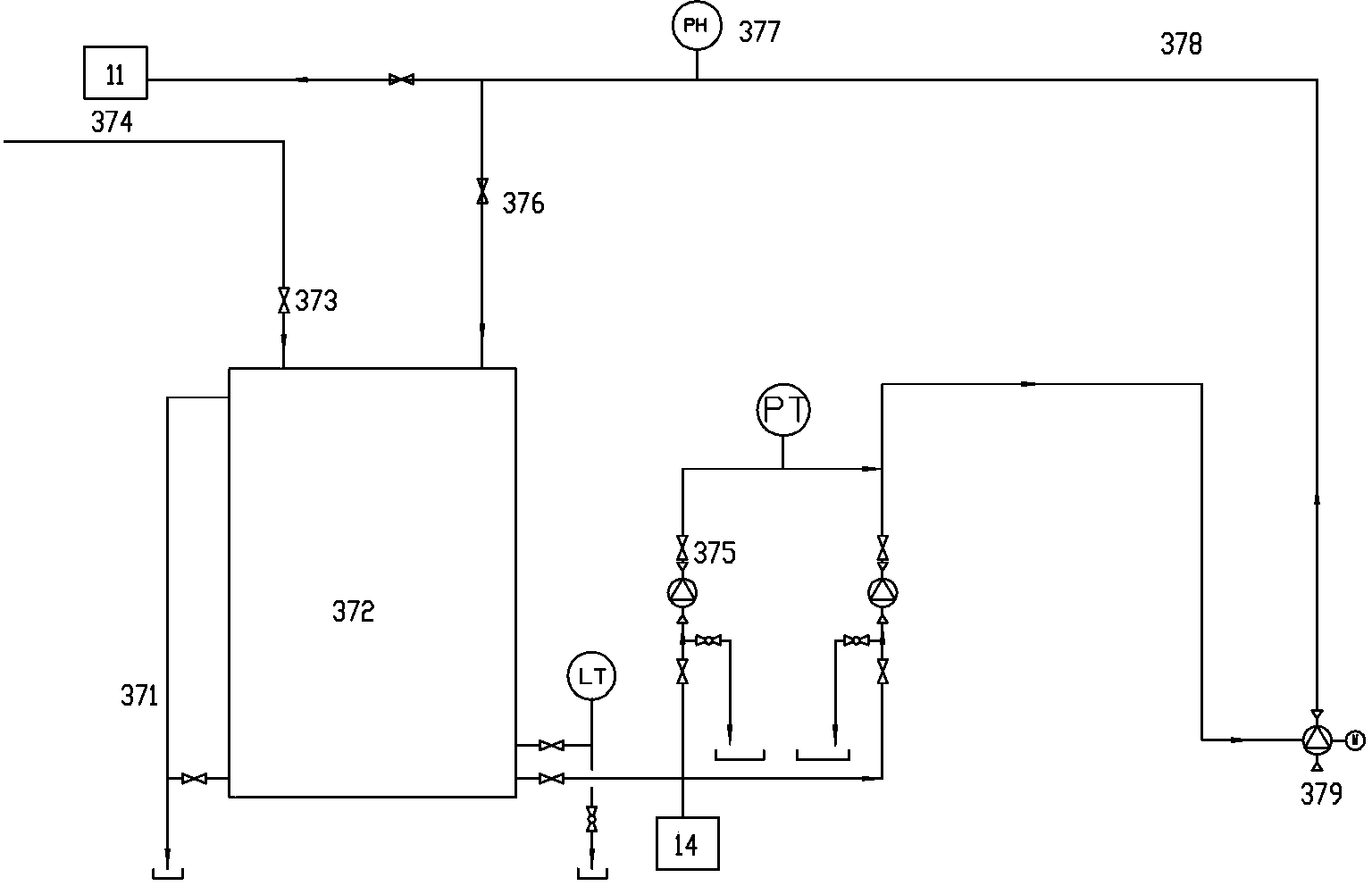

[0081] like figure 1 , 2 Shown in and 3, utilize nickel chloride solution of the present invention to prepare nickel oxide and reclaim the equipment of hydrochloric acid, comprise roasting furnace 24, the combustion-supporting air pipeline 20 that is connected with this roasting furnace 24, natural gas pipeline 22, double cyclone separator 19 respectively , be provided with the burner that is arranged in tangential line on this roaster 24 body, be arranged at the discharging equipment of this roasting furnace bottom, the nickel oxide chunk breaker that is connected with this discharging equipment and the chlorine remover 25 that connects successively, oxidation Object powder pneumatic conveying system 249, feed bin 27, packaging machine 28, dust remover 26, nickel chloride solution tank 15, solution filter 1...

PUM

| Property | Measurement | Unit |

|---|---|---|

| magnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com