Method for treating desulfurization wastewater by electrolysis

A technology for electrolytic treatment and desulfurization wastewater, applied in chemical instruments and methods, multi-stage water/sewage treatment, water/sludge/sewage treatment, etc., can solve the problem that COD is difficult to meet the standard, achieve good treatment effect, and simple operation , the effect of saving medicine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

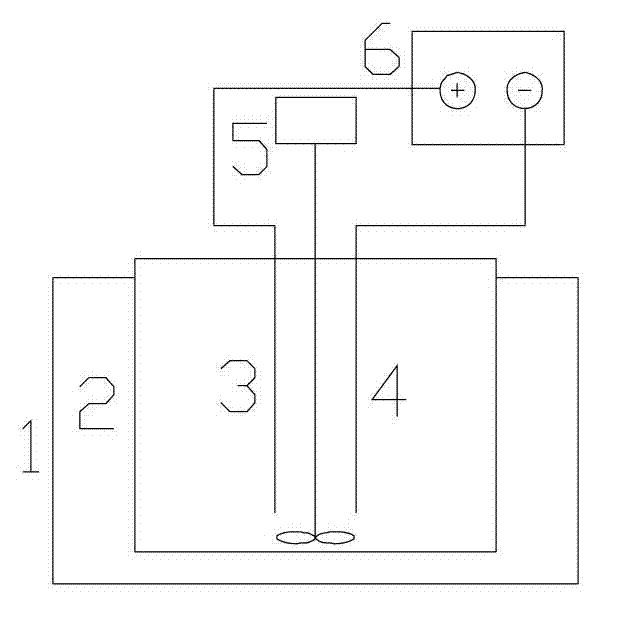

Image

Examples

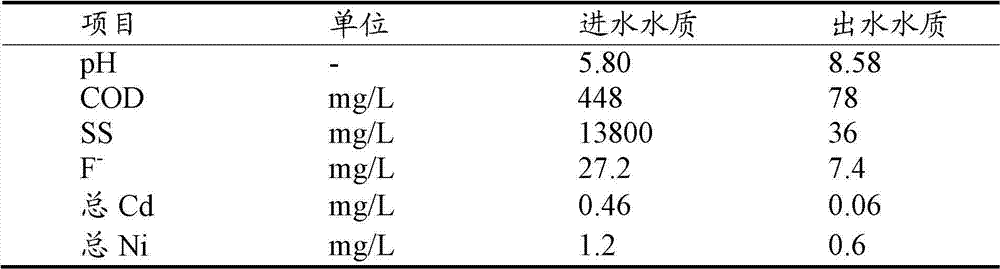

Embodiment 1

[0050] Take 800ml of calcium carbide slag-gypsum desulfurization wastewater and place it in an electrolytic cell with a volume of 1050ml. The ruthenium-based coated titanium electrode is used as the anode, and the size of the ruthenium-based coated titanium electrode is 120mm*50mm*1mm. Customized by Industry Co., Ltd., the stainless steel plate is used as the cathode, stirred with a stirrer, heated and energized for electrolysis, and electrolyzed while stirring. Then add polyacrylamide to the effluent of electrolytic treatment at 8 mg / L for flocculation, and measure the pollution indicators of the effluent.

[0051] Electrolysis reaction process parameters: electrode water ratio 1:16, current density 0.75mA / cm 2 , the distance between the plates is 15mm, and the electrolysis temperature is 30°C. The stirring intensity is 250r / min, the electrolytic reaction time is 60min, and the power consumption is 0.27kwh / t.

[0052] The experimental results are as follows:

[0053]

...

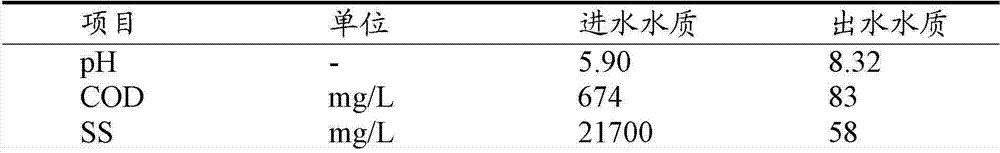

Embodiment 2

[0056] Take 800ml of white mud-gypsum desulfurization wastewater and place it in an electrolytic cell with a volume of 1050ml. The ruthenium-based coated titanium electrode is used as the anode. The size of the ruthenium-based coated titanium electrode is 120mm*50mm*1mm. Customized by Industry Co., Ltd., the stainless steel plate is used as the cathode, stirred with a stirrer, heated and energized for electrolysis, and electrolyzed while stirring. Then add polyacrylamide to 10 mg / L of electrolytic treatment effluent for flocculation, and measure the pollution indicators of effluent.

[0057] Electrolysis reaction process parameters: electrode water ratio 1:16, current density 1.0mA / cm 2 , the distance between the plates is 10mm, and the electrolysis temperature is 40°C. The stirring intensity is 250r / min, the electrolytic reaction time is 60min, and the power consumption is 0.36kwh / t.

[0058] The experimental results are as follows:

[0059]

[0060]

[0061] It can ...

Embodiment 3

[0063] Take 800ml of another white mud-gypsum method desulfurization wastewater and place it in an electrolytic cell with a volume of 1050ml. The ruthenium-based coated titanium electrode is used as the anode. The size of the ruthenium-based coated titanium electrode is 120mm*50mm*1mm. Customized by Xin Titanium Industry Co., Ltd., the stainless steel plate is used as the cathode. Stir with a stirrer and heat and energize for electrolysis. Electrolyze while stirring. Then add polyacrylamide to the effluent of electrolytic treatment at 9 mg / L for flocculation, and measure the pollution indicators of the effluent.

[0064] Electrolysis reaction process parameters: electrode water ratio 1:8, current density 2.0mA / cm 2 , the distance between the plates is 20mm, and the electrolysis temperature is 25°C. The stirring intensity is 400r / min, the electrolytic reaction time is 80min, and the power consumption is 0.72kwh / t.

[0065] The experimental results are as follows:

[0066] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com