AlN whisker/Al2O3 ceramic matrix composite plate substrate and preparation process thereof

A composite material and ceramic-based technology, which is applied to the field of ceramic substrates containing whiskers and the preparation process thereof, can solve the problems of low thermal conductivity and high cost of AlN-based ceramic substrates, reduce sintering temperature, avoid high-temperature oxidation weaknesses, increase The effect of the thermal path

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

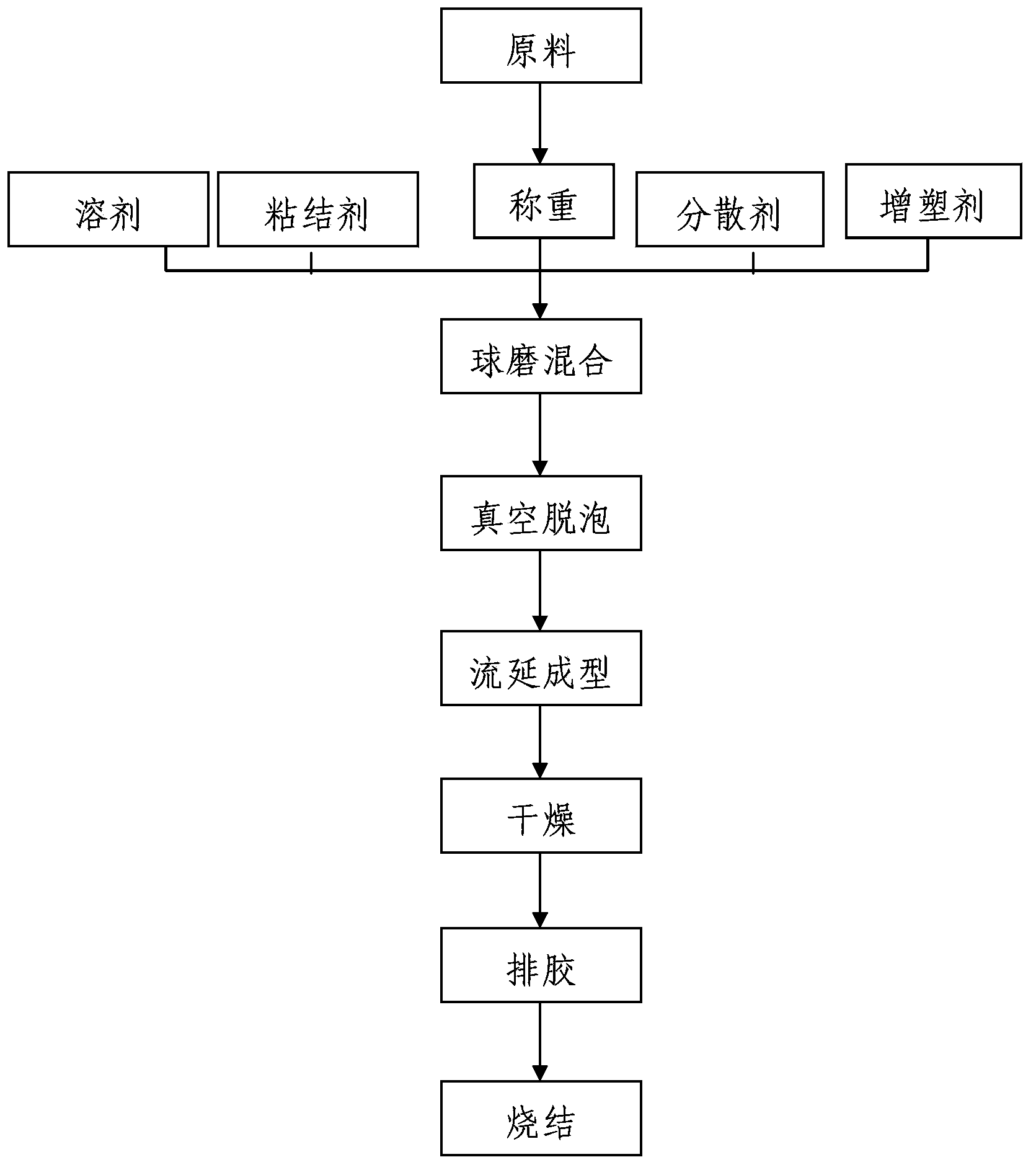

[0028] See figure 1 Flow chart. Take Al with an average particle size of 1μm 2 O 3 400g powder, 400g AlN whiskers with a diameter of 1μm and an aspect ratio of 10-12, and a glass sintering aid CaO-B with a particle size of 0.5μm 2 O 3 -SiO 2 200g, add 830g of absolute ethanol solvent, 40g of triolein dispersant, 125g of polyvinyl butyral PVB binder, and 83g of polyethylene glycol plasticizer, and perform ball milling and mixing for 24 hours to prepare a casting slurry material.

[0029] The ball-milled casting slurry is vacuum degassed using a vacuum pump (vacuum degree -0.1MPa) to eliminate the air mixed into the slurry in the ball mill, and the slurry degassed by vacuum is passed through a 200-mesh screen. The casting slurry that has been vacuum degassed and sieved is allowed to stand for 30 minutes and then molded on a casting machine to form a 1mm thick ceramic green tape. The ceramic green tape is demolded from the casting machine and passed through 180℃ Of hot air for dry...

Embodiment 2

[0032] Take Al with an average particle size of 0.8μm 2 O 3 400g powder, 350g AlN whisker with a whisker diameter of 1μm and an aspect ratio of 10-12, a glass sintering aid CaO-B with a grain size of 0.5μm 2 O 3 -SiO 2 250g of glass, add 850g of absolute ethanol solvent, 40g of trioleate dispersant, 125g of polyvinyl butyral PVB binder, and 83g of polyethylene glycol plasticizer, ball mill and mix for 20 hours to prepare a cast Slurry. The ball-milled casting slurry is vacuum degassed using a vacuum pump (vacuum degree -0.1MPa) to eliminate the air mixed into the slurry in the ball mill, and the slurry degassed by vacuum is passed through a 200-mesh screen. The casting slurry that has been vacuum degassed and sieved is allowed to stand for 40 minutes, and then molded on a casting machine to form a 1mm thick ceramic green tape. The ceramic green tape is demolded from the casting machine and passed through 150℃ Of hot air for drying. The dried ceramic green tape is sliced and ...

Embodiment 3

[0034] Take Al with a particle size of 0.75μm 2 O 3 500g powder, 250g AlN whisker with a whisker diameter of 1.5μm and an aspect ratio of 10-15, a low-temperature glass sintering aid CaO-B with a grain size of 0.5μm 2 O 3 -SiO 2 200g glass, 50g yttrium oxide with a particle size of 0.5μm, add 820g absolute ethanol solvent, 45g trioleate dispersant, 145g polyvinyl butyral PVB binder, and 80g polyethylene glycol plasticizer. Ball mill mixing for 15 hours to prepare casting slurry. The ball-milled casting slurry is vacuum degassed using a vacuum pump (vacuum degree -0.1MPa) to eliminate the air mixed into the slurry in the ball mill, and the slurry degassed by vacuum is passed through a 200-mesh screen. After the casting slurry that has been vacuum degassed and sieved is allowed to stand for a period of time, it is molded on a casting machine to form a ceramic green tape with a thickness of 0.75 mm. The ceramic green tape is demolded from the casting machine and passed through 150 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com