Preparation method of aluminum-zinc-magnesium-copper-zirconium series high-strength aluminum alloy

A technology of aluminum zinc magnesium and aluminum alloy, which is applied in the field of light-weight high-performance structural aluminum alloy materials and powder metallurgy, can solve the problems of cumbersome preparation process, coarse grain, low solid solubility, etc. The effect of low production rate and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

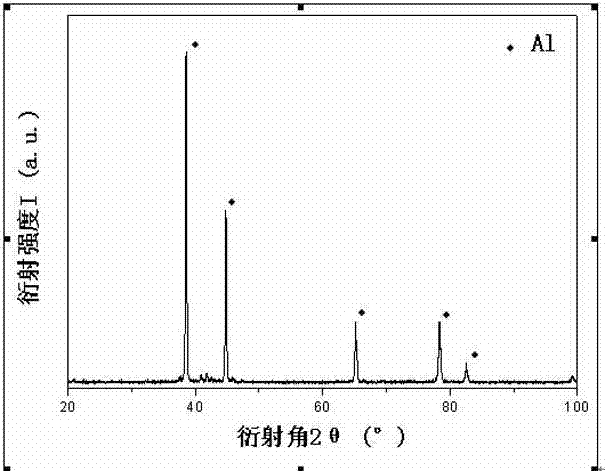

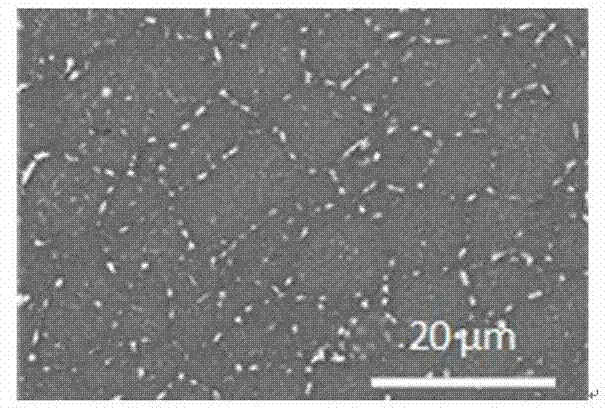

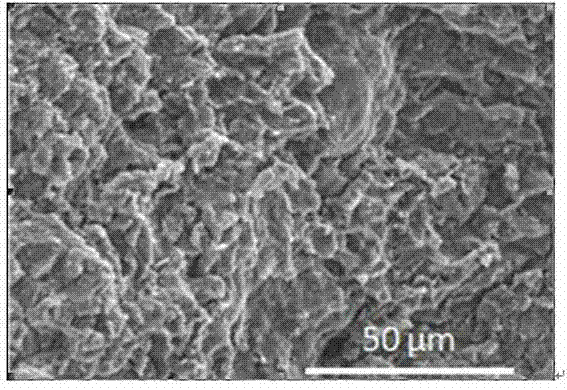

[0023] The chemical composition of the experimental alloy is: Al-6.5Zn-2.1Mg-2.1Cu-0.17Zr (mass fraction), the alloy ingredients are 10μm copper powder, 2μm aluminum powder, 20μm magnesium powder, 6~9μm zinc powder and 2~3μm zirconium powder . The element powder is ball milled on a light ball mill at a speed of 150 rpm for 24 hours, and the composite body is sintered in a vacuum hot-pressed sintering furnace at a low temperature and high pressure under vacuum, with a vacuum degree of ≤0.01Pa, a sintering temperature of 550°C, and a sintering time of 3 hours. , the sintering pressure is 80MPa, high-temperature solution heat treatment is carried out on the sintered body sintered by low-temperature, high-pressure vacuum hot pressing, the temperature is 620°C, the vacuum degree is ≤0.01Pa, and the sintering time is 12h. The sintered sample is hot-extruded, extruded The preheating temperature of the front mold is 480°C, the extrusion ratio is 4:1, and the extrusion speed is 1.4m / mi...

Embodiment 2

[0025] The chemical composition of the experimental alloy is: Al-6.1Zn-2.1Mg-1.6Cu-0.25Zr (mass fraction), and the alloy ingredients are 10μm copper powder, 10μm aluminum powder, 20μm magnesium powder, 6~9μm zinc powder and 2~3μm zirconium powder . The element powder is ball milled on a light ball mill at a speed of 250 rpm for 36 hours, and the composite body is sintered in a vacuum hot-pressed sintering furnace at a low temperature and high pressure under vacuum, with a vacuum degree of ≤0.01Pa, a sintering temperature of 550°C, and a sintering time of 2 hours. , the sintering pressure is 60MPa, high-temperature solution heat treatment is carried out on the sintered body sintered by low temperature and high pressure vacuum hot pressing, the temperature is 600°C, the vacuum degree is ≤0.01Pa, and the sintering time is 5h. The sintered sample is subjected to hot extrusion, extrusion The preheating temperature of the front mold is 480°C, the extrusion ratio is 4:1, and the extr...

Embodiment 3

[0027] The chemical composition of the experimental alloy is: Al-5.0Zn-1.7Mg-2.1Cu-0.25Zr (mass fraction), the alloy ingredients are 10μm copper powder, 10μm aluminum powder, 20μm magnesium powder, 6~9μm zinc powder and 2~3μm zirconium powder . The element powder is balled on a light ball mill at a speed of 250 rpm for 36 hours. The composite body is sintered in a vacuum hot-pressed sintering furnace at a low temperature and high pressure. , the sintering pressure is 60MPa, high-temperature solution heat treatment is carried out on the sintered body sintered by low-temperature high-pressure vacuum hot pressing, the temperature is 610°C, the vacuum degree is ≤0.01Pa, and the sintering time is 8h. The sintered sample is hot-extruded, extruded The preheating temperature of the front mold is 480°C, the extrusion ratio is 4:1, and the extrusion speed is 1.4m / min. The extruded parts are subjected to primary solid solution at 470°C for 2 hours, and then heated to 485°C for secondary ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com