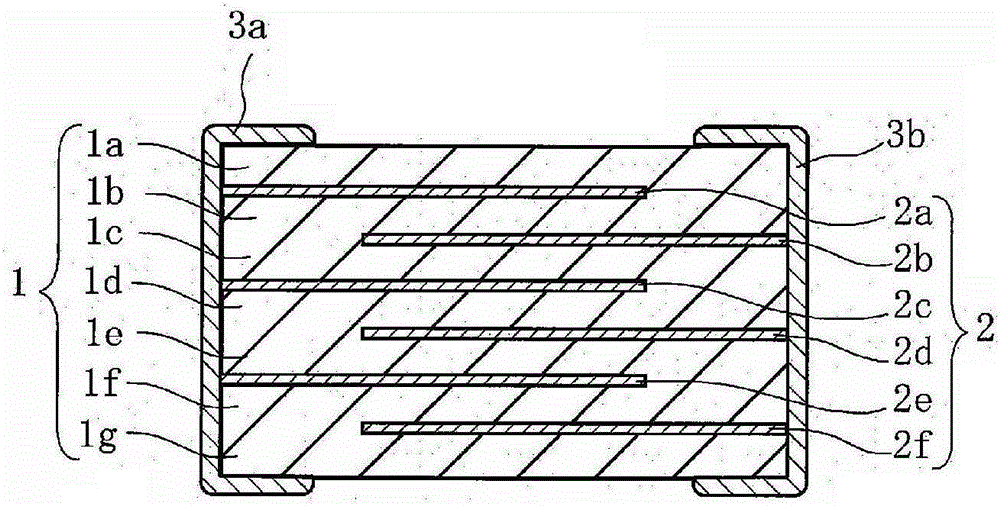

Method for manufacturing multilayer semiconductor ceramic capacitor, and multilayer semiconductor ceramic capacitor

A technology for ceramic capacitors and a manufacturing method, applied in the directions of multilayer capacitors, fixed capacitor dielectrics, capacitors, etc., can solve the problems of high cost, large-scale device, increase in the number of parts, etc., and achieve cost reduction, realization of the number of parts, suppression of The effect of peak voltage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0084] 〔Sample making〕

[0085] Prepare SrCO as the original raw material of ceramics 3 , to prepare a specific surface area of 30m 2 / g (average particle size: about 30nm) TiO 2 , and LaCl as the donor compound 3 . In addition, LaCl was weighed so that the content of La was 0.8 mol with respect to 100 mol of Ti element. 3 , and further weigh SrCO so that the mixed molar ratio m (=Sr site / Ti site) of Sr site and Ti site becomes 1.008 3 and TiO 2 .

[0086] Then, with respect to 100 parts by weight of these weighing objects, after adding 3 parts by weight of polycarboxylate ammonium salt as a dispersant, PSZ balls with a diameter of 2 mm and pure water are thrown into a ball mill together as a grinding medium, and 16 parts by weight are carried out in the ball mill. Hours of wet mixing made the slurry.

[0087] Next, after evaporating and drying the slurry, a calcining treatment was performed at a temperature of 1400° C. for 2 hours in the air atmosphere to obtain a c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| capacitance | aaaaa | aaaaa |

| capacitance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com