Natural preservative regarding lotus leaves as raw material and preparation method thereof

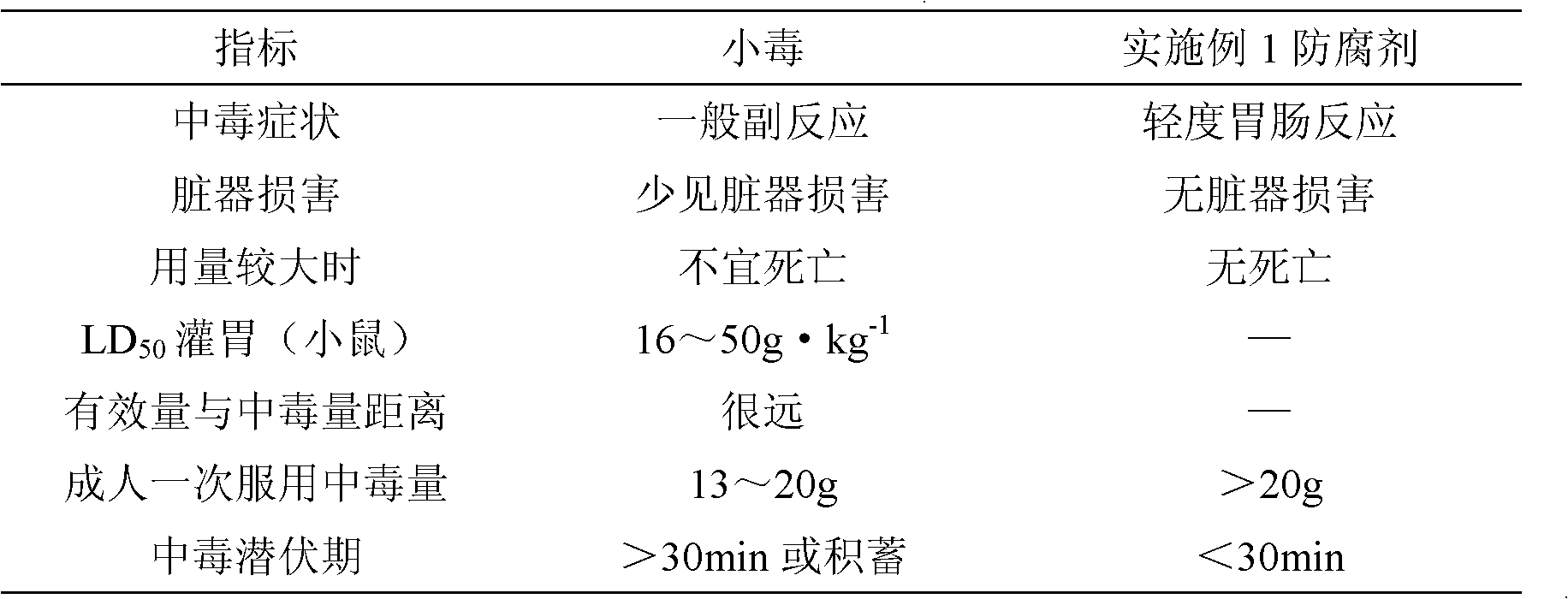

A technology of natural preservatives and raw materials, applied in the field of food additives, can solve problems such as adverse effects on the natural ecological environment, poisoning, etc., and achieve the effects of improving practical application significance, high food safety, and high safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

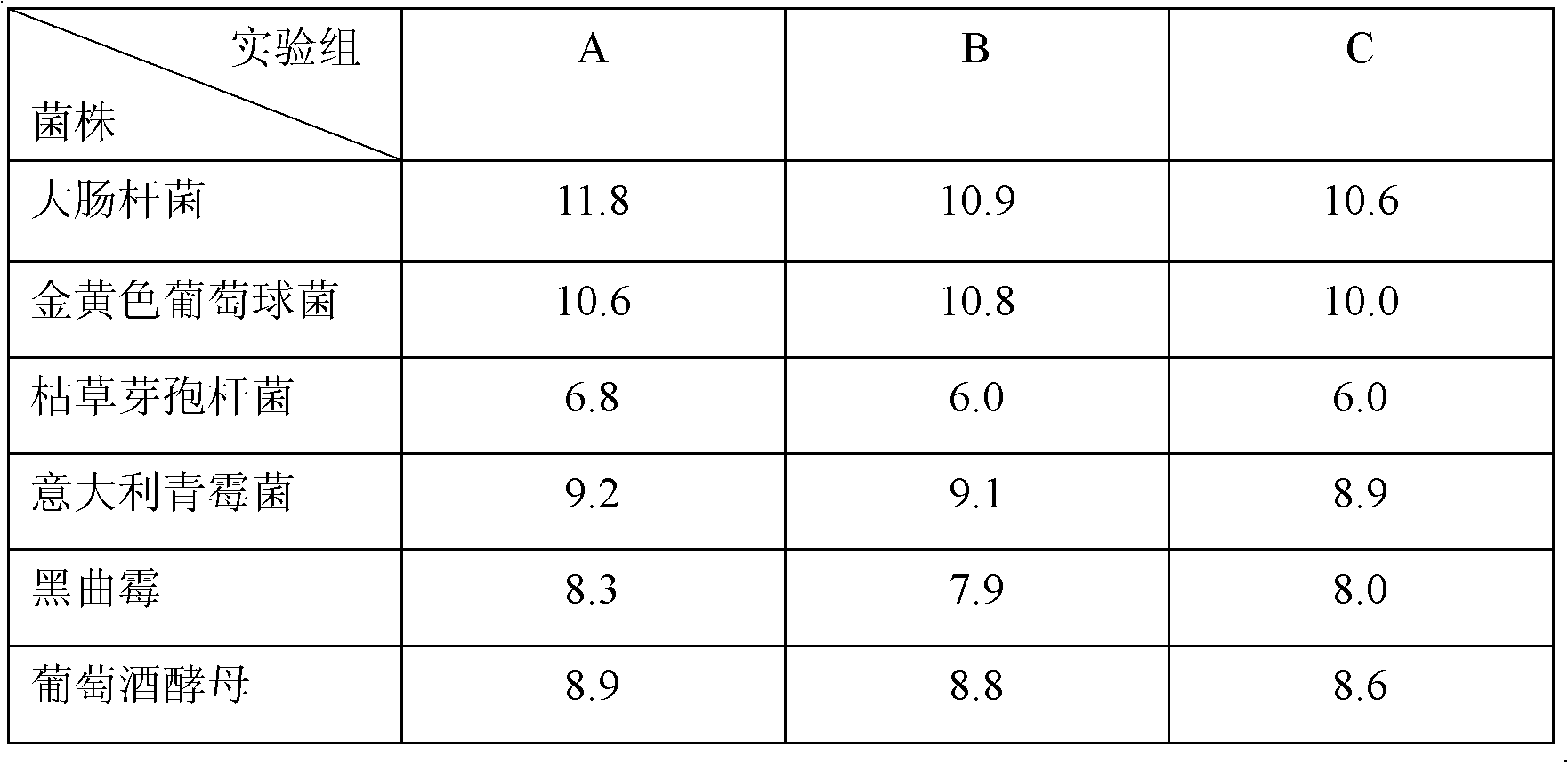

Examples

Embodiment 1

[0022] (1) Fresh lotus leaves were soaked in phosphoric acid aqueous solution (pH 3.0) containing 0.1% NaCl by mass percentage for 3 minutes at room temperature, washed and drained with distilled water, dried to a water content below 8%, and crushed through a 40-mesh sieve.

[0023] (2) Take 1kg of lotus leaf powder, put it into a round-bottomed flask, carry out decompression heat reflux extraction, use volume percentage concentration as 80% ethanol solution circulation leaching 2h, the mass ratio of extracting liquid and lotus leaf powder is 10 : 1, the extraction temperature is 50°C. After the leaching is finished, the extract is collected, concentrated in a rotary evaporator to obtain the lotus leaf extract extract, which is subjected to vacuum freeze-drying and pulverized to obtain the lotus leaf extract.

[0024] (3) According to the mass ratio of lotus leaf extract, citric acid and soluble starch of 8, 3, and 3, the three component raw materials were mixed to obtain the ...

Embodiment 2

[0026] (1) Fresh lotus leaves were soaked in phosphoric acid aqueous solution (pH 3.2) containing 0.1% NaCl by mass percentage for 3 minutes at room temperature, washed and drained with distilled water, dried to a moisture content below 8%, and crushed through a 40-mesh sieve.

[0027] (2) Take 1kg of lotus leaf powder, put it into a round-bottomed flask, carry out decompression heat reflux extraction, use volume percentage concentration as 80% ethanol solution circulation leaching 2h, the mass ratio of extracting liquid and lotus leaf powder is 10 : 1, the extraction temperature is 50°C. After the leaching is finished, the extract is collected, concentrated in a rotary evaporator to obtain the lotus leaf extract extract, which is subjected to vacuum freeze-drying and pulverized to obtain the lotus leaf extract.

[0028] (3) According to the mass ratio of lotus leaf extract, citric acid and soluble starch of 6, 2, and 2, the three component raw materials were mixed to obtain t...

Embodiment 3

[0030] (1) Fresh lotus leaves were soaked in phosphoric acid aqueous solution (pH 3.5) containing 0.1% NaCl by mass percentage for 3 minutes at room temperature, washed and drained with distilled water, dried to a moisture content below 8%, and crushed through a 40-mesh sieve.

[0031] (2) Take 1kg of lotus leaf powder, put it into a round-bottomed flask, carry out decompression heat reflux extraction, use volume percentage concentration as 80% ethanol solution circulation leaching 2h, the mass ratio of extracting liquid and lotus leaf powder is 10 : 1, the extraction temperature is 50°C. After the leaching is finished, the extract is collected, concentrated in a rotary evaporator to obtain the lotus leaf extract extract, which is subjected to vacuum freeze-drying and pulverized to obtain the lotus leaf extract.

[0032] (3) According to the mass ratio of lotus leaf extract, citric acid and soluble starch of 4, 1, 3, the three component raw materials were mixed to obtain the n...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com