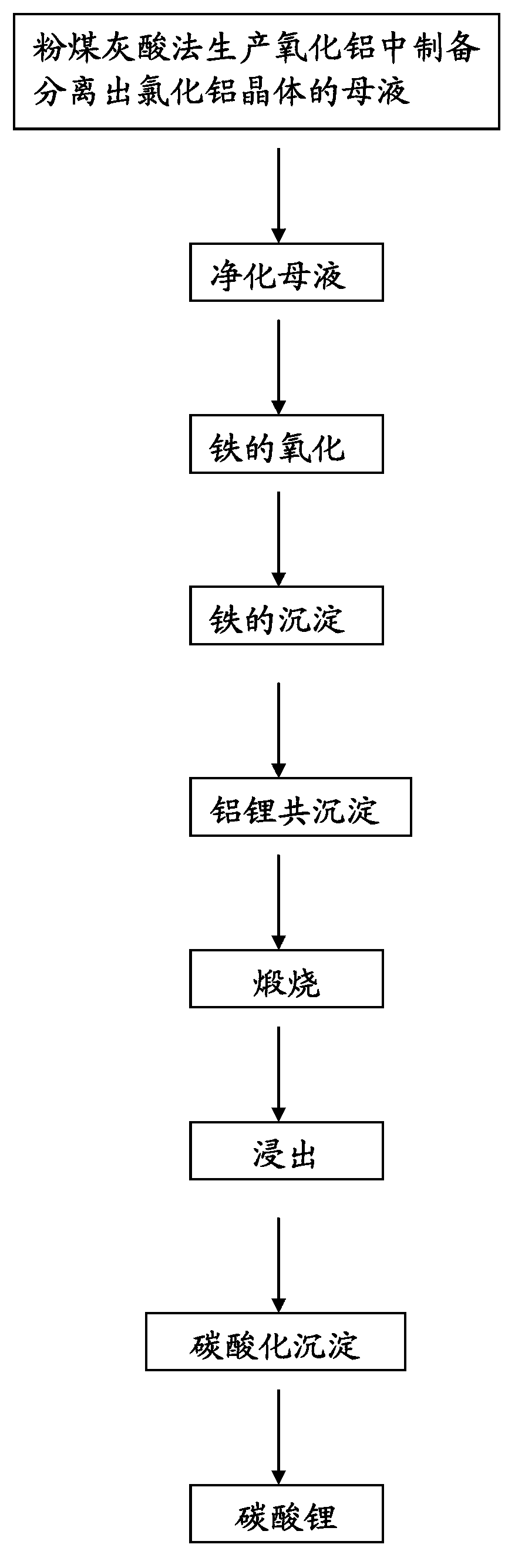

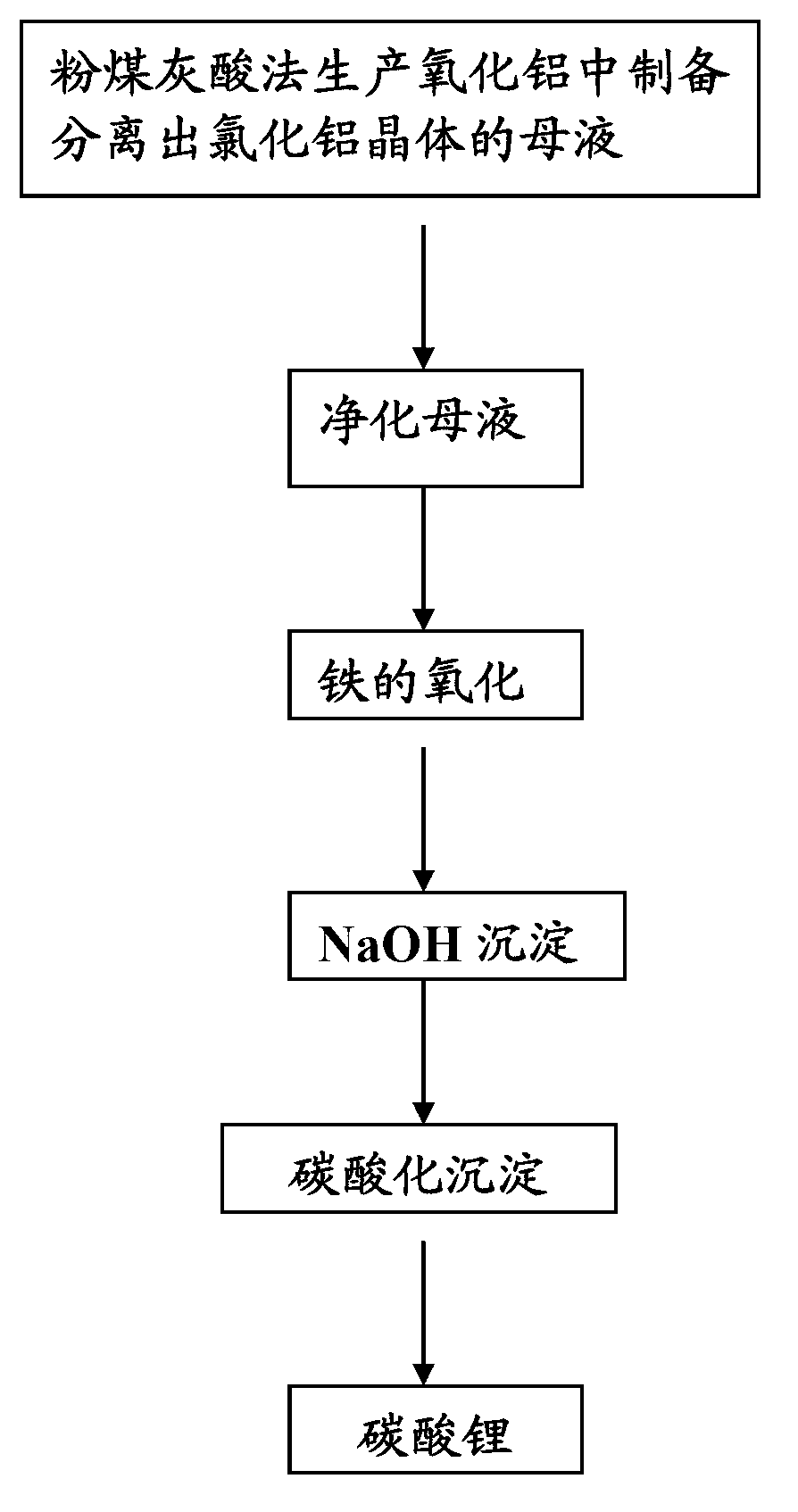

Method for preparing lithium carbonate from coal ash

A technology of fly ash and lithium carbonate, applied in the direction of lithium carbonate;/acid carbonate, solid waste removal, etc., to achieve the effect of comprehensive utilization and improvement of economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0066] Filter the mother liquor to make the content of floating substance less than 0.01g / L, take 1L and heat it to 74°C, add H to the solution 2 o 2 15mL, to oxidize all the ferrous ions to ferric ions; then add ammonia water dropwise to the solution, adjust the pH to 1.9, and filter out the iron ions in the solution. Slowly add 3.9 L of 1.8 mol / L sodium hydroxide solution dropwise to the solution under constant stirring, continue stirring the solution for 1 hour and then filter to obtain a precipitate, which weighs 98.2 g after drying. Place the precipitate in a muffle furnace, calcinate at 200°C for 90 minutes, leach the clinker with warm water at 50°C, control the liquid-solid ratio during leaching to 5:1, and filter for 60 minutes. At normal temperature, 20g of sodium carbonate was added to the filtrate, filtered and dried after 20 minutes to obtain 1.83g of lithium carbonate product with a product purity of 92%.

Embodiment 2

[0068] Filter the mother liquor to make the content of floating substance less than 0.01g / L, take 1L and heat it to 68°C, add H to the solution 2 o 2 15mL to oxidize all iron ions into ferric ions. Add ammonia water dropwise to the solution, adjust the pH value to 2.6, and filter out the iron ions in the solution. Slowly add 3.7L of 2.3moL / L sodium hydroxide solution dropwise to the solution under constant stirring, continue to stir the solution for 1 hour and then filter to obtain a precipitate, which weighs 93.2g after drying. Place the precipitate in a muffle furnace, calcinate at 400°C for 60 minutes, leach the clinker with warm water at 55°C, control the liquid-solid ratio during leaching to 10:1, and filter for 60 minutes. At normal temperature, 20g of sodium carbonate was added to the filtrate, filtered and dried after 20 minutes to obtain 1.63g of lithium carbonate product with a product purity of 96.3%.

Embodiment 3

[0070] Filter the mother liquor to make the content of floating substance less than 0.01g / L, take 1L and heat it to 43°C, add KMnO to the solution 4 so that all iron ions are oxidized into ferric ions; and low-concentration sodium hydroxide is added dropwise to the solution to adjust the pH to 2.0, so that the iron ions in the solution are precipitated and then filtered. Slowly add 3.9 L of 1.8 mol / L sodium hydroxide solution dropwise to the solution under constant stirring, continue stirring the solution for 1 hour and filter to obtain a precipitate, which weighs 97.1 g after drying. Place the precipitate in a muffle furnace, calcinate at 500°C for 50 minutes, leach the clinker with warm water at 60°C, control the liquid-solid ratio to 8:1 during leaching, and filter for 80 minutes. At room temperature, add 20 g of sodium carbonate to the filtrate, filter and dry after 20 minutes. Obtain lithium carbonate product 1.89g, product purity is 95.4%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com