Method for preparing bacterial cellulose by using bagasse

A technology of bacterial cellulose and bagasse, which is applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problem that bagasse is not effectively used, and achieve the improvement of economic utilization value, large processing capacity, and raw material Effects from a wide range of sources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

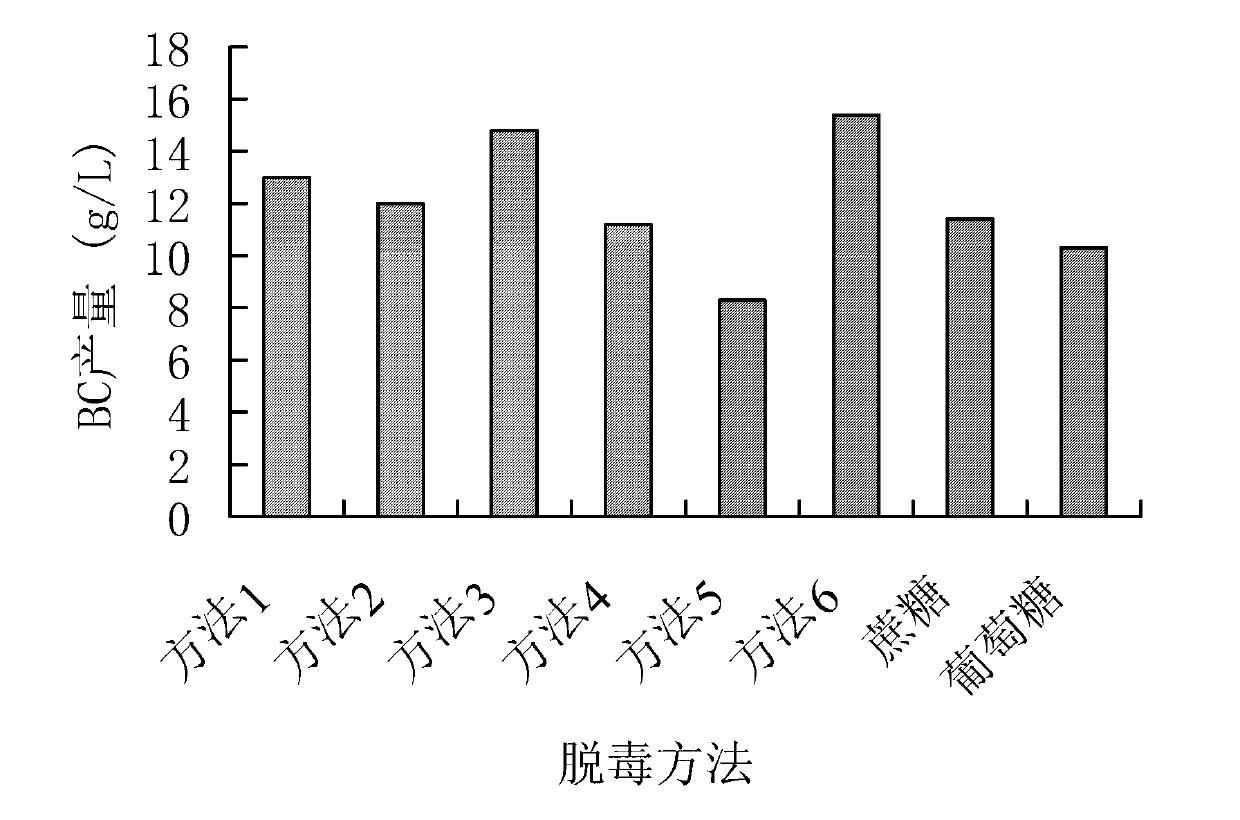

Embodiment 1

[0034] The bagasse is first ground with a plant grinder, and then soaked in dilute sulfuric acid (3%, w / v) in the reactor at a solid / liquid ratio of 1:6 bagasse to dilute acid solution overnight (12-24h). Then react at a temperature of 180°C for 60 minutes, then separate the bagasse residue and the acid solution by suction filtration, collect the hydrolyzate, and refrigerate at 4°C for later use.

[0035]Add NaOH to adjust the pH value of the hydrolyzed liquid to about 10, filter the precipitate with filter paper to obtain the treated hydrolyzed liquid, and then fine-tune the pH value to 10.0. Then seal it with a film, place it in a 30°C water bath for 12-24 overnight, and finally adjust the pH value of the hydrolyzate to 5.0 with dilute acid. Then add 2% (mass percentage) activated carbon, stir (5-10min at room temperature) and filter out the activated carbon with filter paper to obtain a detoxified hydrolyzed liquid, then fine-tune the pH value to 5.0-5.5 with dilute sulfuri...

Embodiment 2

[0037] Bagasse is first ground with a plant grinder, and then soaked overnight (12-24h) in a reactor with dilute hydrochloric acid (1%, w / v) at a solid / liquid ratio of 1:10 bagasse to dilute acid solution, Then react at a temperature of 240°C for 75 minutes, then separate the bagasse residue and the acid solution by suction filtration, collect the hydrolyzate, and refrigerate at 4°C for later use.

[0038] Add Ca(OH) 2 Adjust the pH value of the hydrolyzed liquid to about 10, filter out the precipitate with filter paper to obtain the treated hydrolyzed liquid, and then fine-tune the pH value to 10.0. Then seal it with a film, place it in a 40°C water bath for 12-24 overnight, and finally adjust the pH value of the hydrolyzate to 5.0 with dilute acid. Then add 2% (mass percentage) of activated carbon, stir (5-10min at room temperature) and filter out the activated carbon with filter paper to obtain a detoxified hydrolyzed liquid, then fine-tune the pH value to 5.5 with dilute ...

Embodiment 3

[0040] Bagasse is first ground with a plant grinder, and then soaked overnight (12-24h) in a reactor with dilute sulfuric acid (2%, w / v) at a solid / liquid ratio of bagasse to dilute acid solution of 1:15, Then react at a temperature of 200°C for 80 minutes, then separate the bagasse residue and the acid solution by suction filtration, collect the hydrolyzate, and refrigerate at 4°C for later use.

[0041] First wash the anion exchange resin AG1-X8 with clean water for several times, and filter off the washing water for later use. Then add an ion exchange resin to the hydrolyzate in an amount of 3-10w / v% until the pH value is 10. Under the condition of room temperature or 50°C, shake at 90rpm for 30-60min. After the resin is removed by filtration or centrifugation, the treated hydrolyzate is obtained, and then the pH value is finely adjusted to 4-6. The detoxified hydrolyzate is tested for sugar and used as the carbon source of the medium, and then 0.1%-1% of yeast extract an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com