Method for preparing bismuth vanadate solar cell on glass substrate

A technology for solar cells and glass substrates, which is applied in the manufacture of circuits, electrical components, and final products. It can solve problems that limit the large-scale application of BVO thin films, reduce costs and environmental protection, and complicate the preparation of solid-phase methods to achieve superior photovoltaic performance. , Conducive to environmental protection, good effect of photovoltaic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

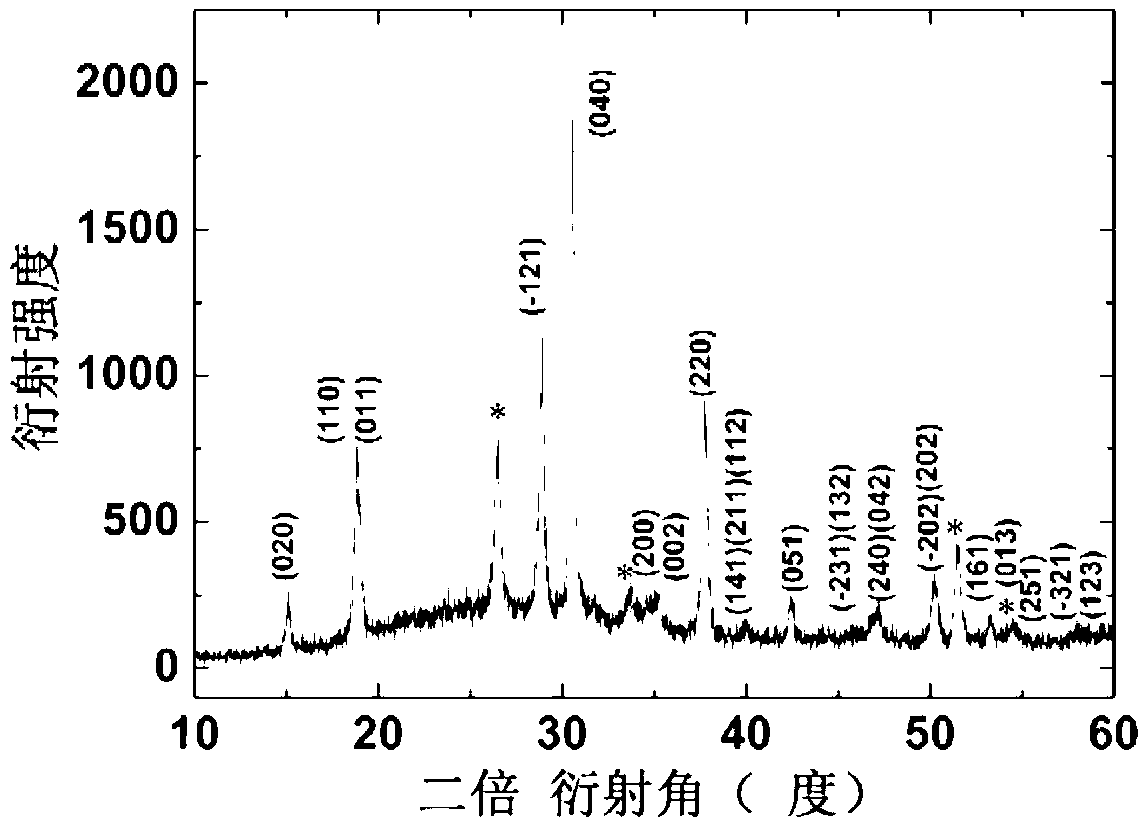

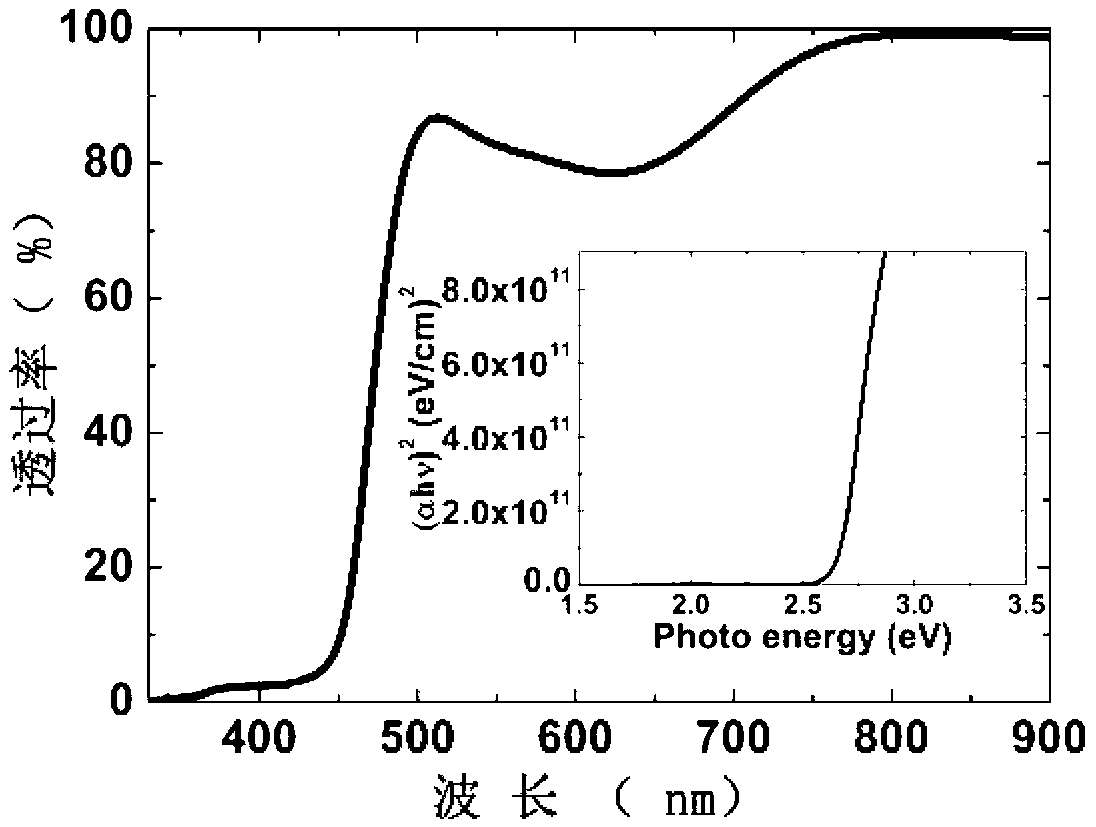

[0025] Bi(NO 3 ) 3 ·5H 2 O and NH 3 VO 3 (Molar ratio according to Bi:V=1:1) was dissolved in DMF with the assistance of citric acid, acetic acid and ethanolamine in proportion to obtain a dark blue and stable precursor solution. Films were then prepared by the gel-spin method. The condition of glue rejection is as follows: 10 seconds at 500 rpm and 30 seconds at 3000 rpm. After spinning the glue, dry the substrate with the precursor wet film on a hot plate at 350°C for 1 to 3 minutes, and finally dry it in O 2 Sintering at 480° C. for 5 minutes in a rapid annealing furnace under atmosphere. After the first layer is calcined, the first layer is annealed once, and then each layer is annealed once, and a total of 8 layers of glue are thrown to obtain the BVO film.

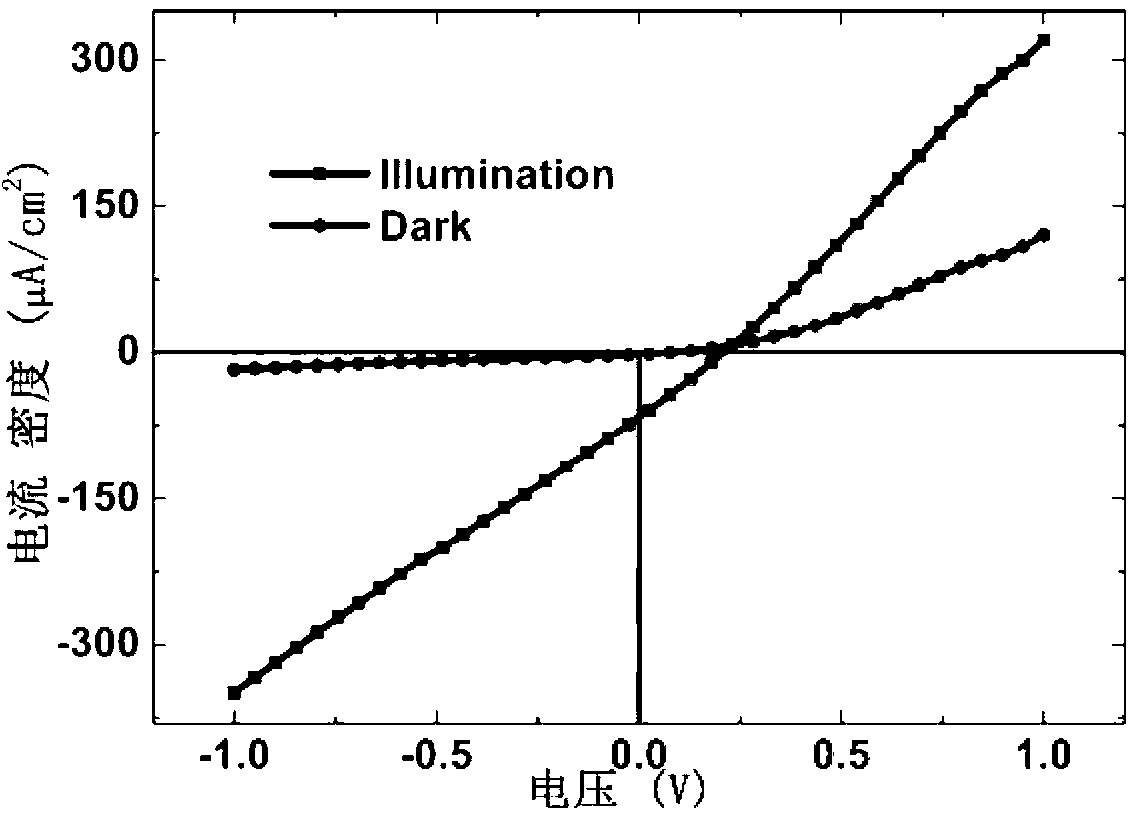

[0026] The prepared thin film was shielded by a mask with a hole of 1 mm × 0.5 mm, and a 1 mm × 0.5 mm Au upper electrode was deposited on the film surface by physical sputtering.

Embodiment 2

[0028] Bi(NO 3 ) 3 ·5H 2 O and NH 3 VO 3 (Molar ratio according to Bi:V=1:1) was dissolved in DMF with the assistance of citric acid, acetic acid and ethanolamine in proportion to obtain a dark blue and stable precursor solution. Films were then prepared by the gel-spin method. The condition of glue rejection is as follows: 10 seconds at 500 rpm and 30 seconds at 3000 rpm. After spinning the glue, dry the substrate with the precursor wet film on a hot plate at 350°C for 1 to 3 minutes, and finally dry it in O 2 Sintering at 500° C. for 5 minutes in a rapid annealing furnace under atmosphere. After calcination of the first layer of glue, anneal once, and anneal once for each layer after that, a total of 8 layers of glue are thrown, and the BVO film is obtained.

[0029] The prepared thin film was shielded by a mask with a hole of 1 mm × 0.5 mm, and a 1 mm × 0.5 mm Au upper electrode was deposited on the film surface by physical sputtering.

Embodiment 3

[0031] Bi(NO 3 ) 3 ·5H 2 O and NH 3 VO 3 (Molar ratio according to Bi:V=1:1) was dissolved in DMF in proportion and with the assistance of citric acid, acetic acid and ethanolamine to obtain a dark blue and stable precursor solution. Films were then prepared by the gel-spin method. The condition of glue rejection is as follows: 10 seconds at 500 rpm and 30 seconds at 3000 rpm. After spinning the glue, dry the substrate with the precursor wet film on a hot plate at 350°C for 1 to 3 minutes, and finally dry it in O 2 Sintering at 520° C. for 5 minutes in a rapid annealing furnace under atmosphere. After calcination of the first layer of glue, anneal once, and anneal once for each layer after that, a total of 8 layers of glue are thrown, and the BVO film is obtained. The prepared thin film was shielded by a mask with a hole of 1 mm × 0.5 mm, and a 1 mm × 0.5 mm Au upper electrode was deposited on the film surface by physical sputtering.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com