White light light-emitting diode (LED) high in temperature resistance and free of fluorescent powder

A phosphor-free, high-temperature-resistant technology, applied in the field of white light LEDs, can solve problems such as inability to ensure uniform distribution of phosphors, easy yellow circles in light color, and low packaging light efficiency, so as to save the link of secondary light distribution , Improve the effective service life of LED, and reduce the loss of blue light ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

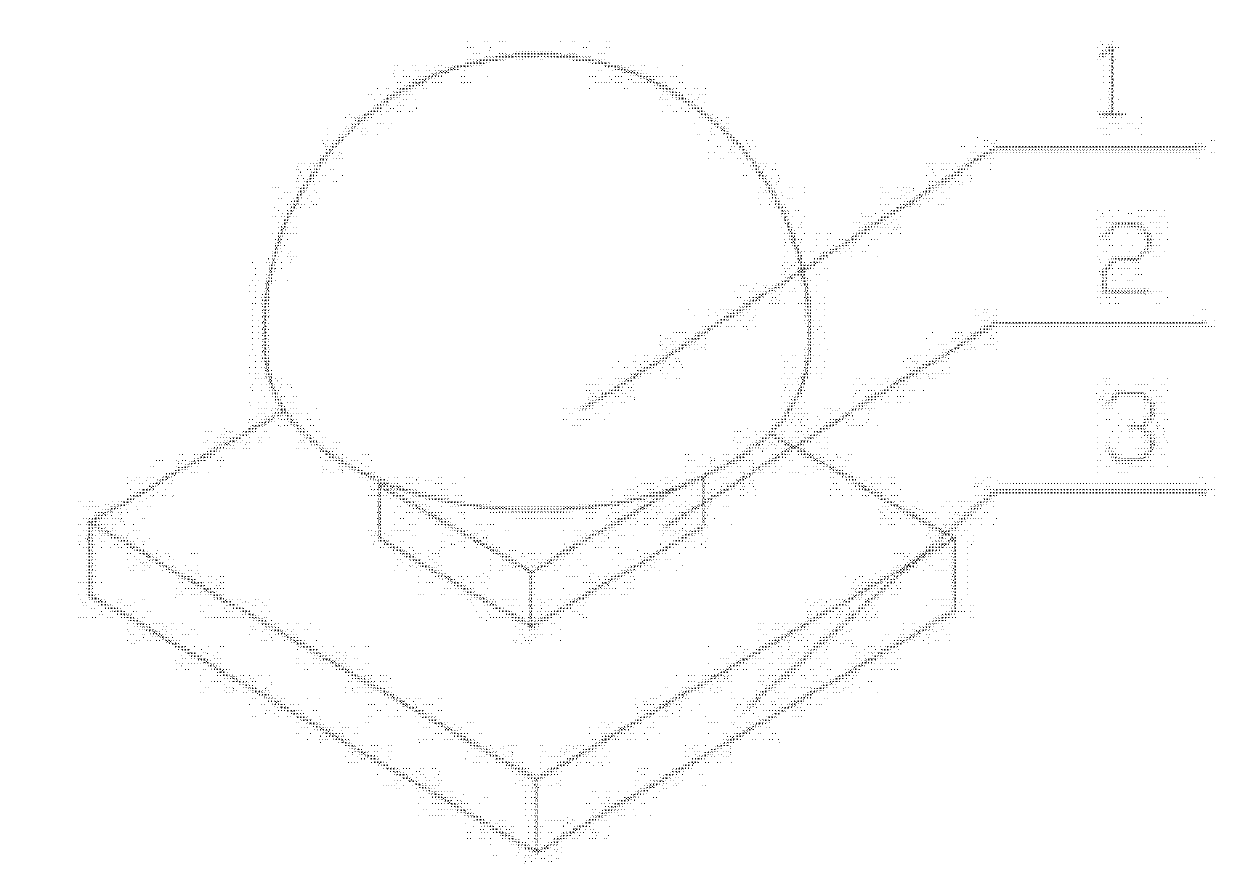

Image

Examples

Embodiment 1

[0034] The glass lens comprises the following steps to make successively: first make the SiO that accounts for 58% of the total moles of the raw material 2 , accounting for 14% of the total moles of the raw material Al 2 o 3 , accounting for 16% of the total moles of the raw material CaF 2 and the ZnO 2 Accounting for 3% ZnO of the total moles of the raw materials 2 Mixing and grinding to a particle size of 60 nanometers; grinding 3% of rare earth oxide europium oxide and cerium oxide to a particle size of 60 nanometers in the total moles of the raw materials; finally mixing the ground glass matrix and rare earth oxides Uniform; then put the above mixed powder into a corundum crucible, then put the crucible into a sintering furnace, and heat it to 1300°C at a speed of 30°C / min and keep the temperature for 30 minutes for melting to obtain molten glass. During the melting process Through the reducing gas hydrogen or carbon monoxide; then quickly pour the molten glass above i...

Embodiment 2

[0036] Same as Example 1, except that the rare earth oxides are praseodymium oxide and erbium oxide.

Embodiment 3

[0038] Same as Example 1, the difference is that the rare earth oxide is YAG: Ce 3+ Phosphor.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com