Battery

A battery and electrolyte technology, applied in the field of electrochemical energy storage, can solve the problems of high technical threshold, inability to meet simultaneously, and high price, and achieve the effects of clear work content, excellent cycle performance, and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

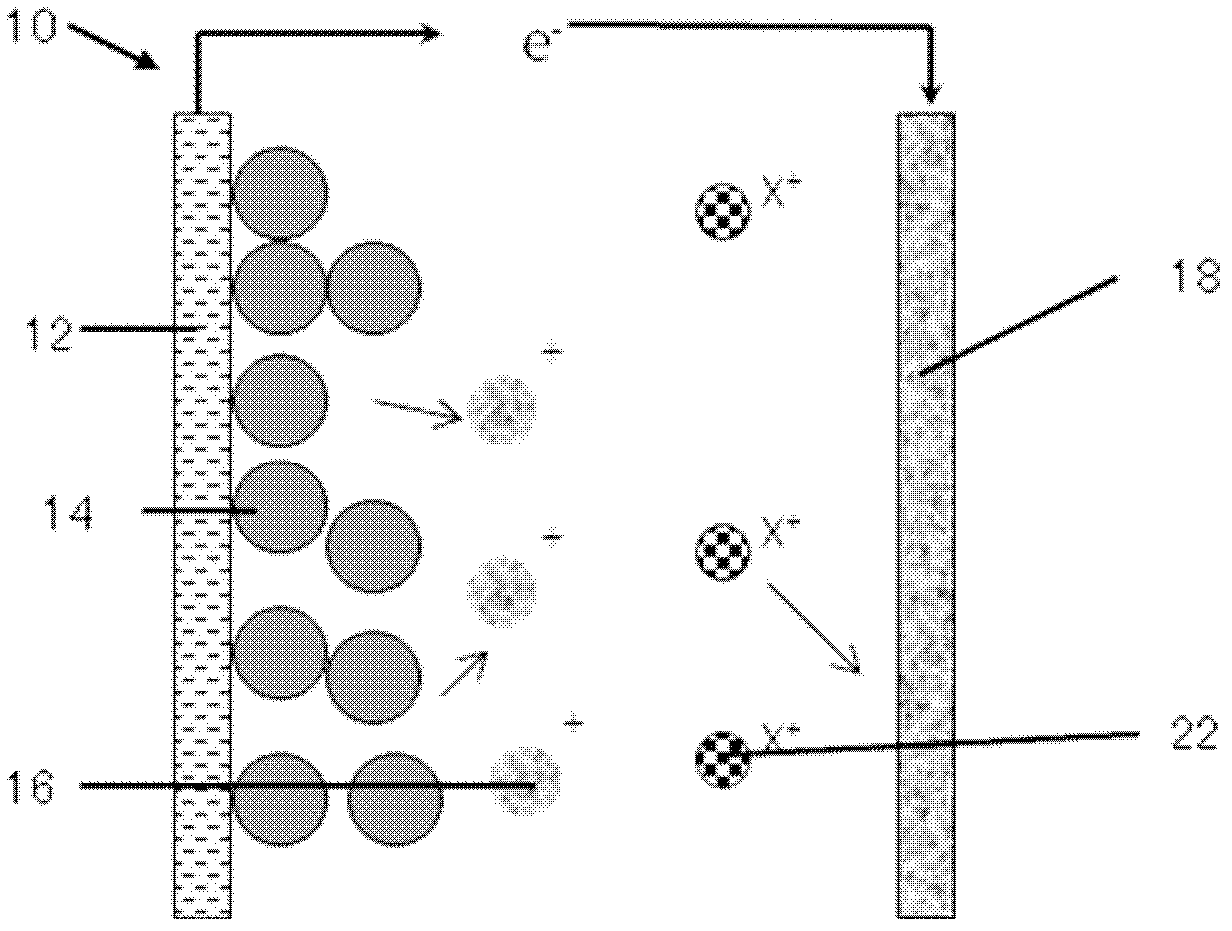

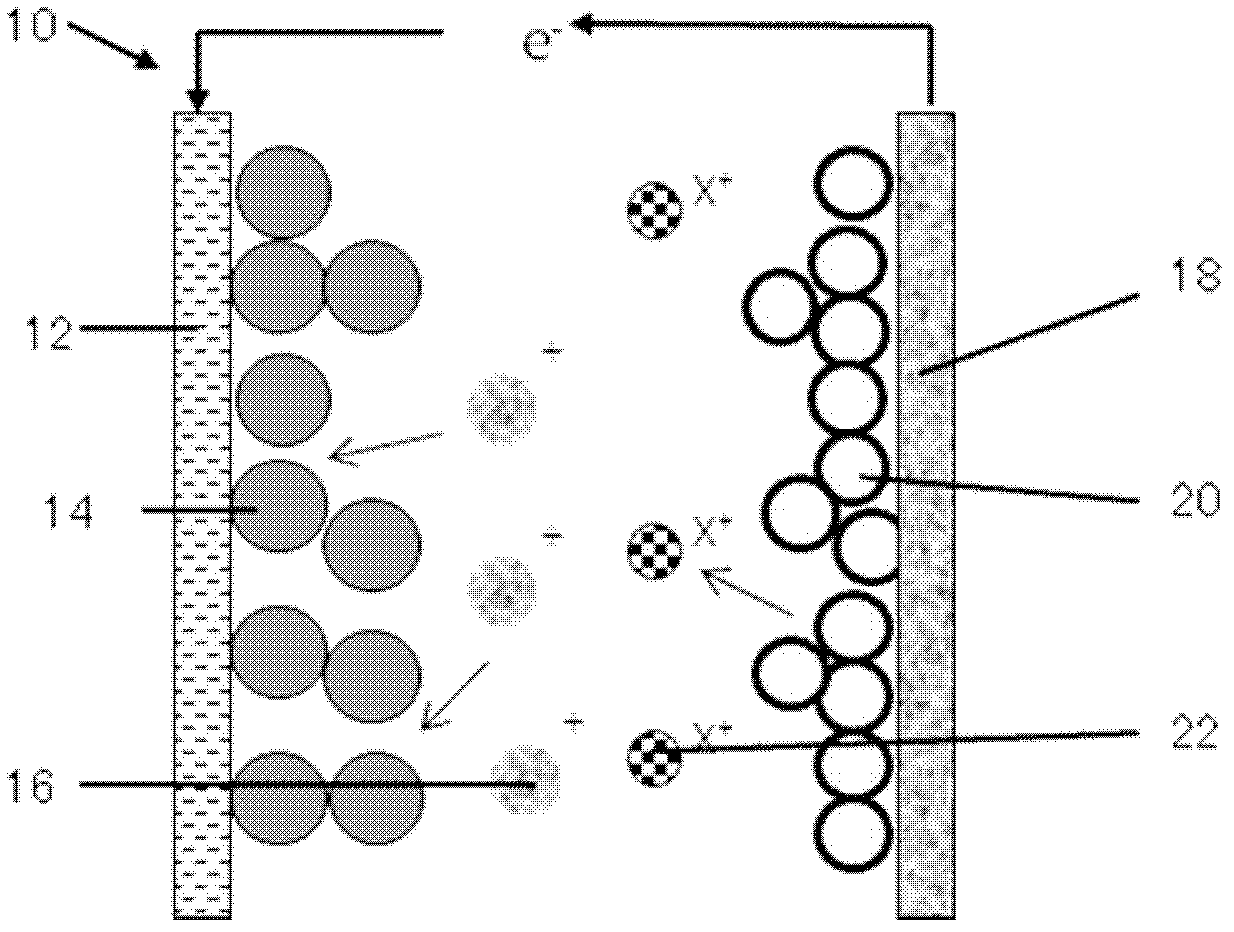

Method used

Image

Examples

Embodiment 1

[0088] The examples in this category are divided into 4 examples, respectively illustrating that different lithium or sodium ion intercalation compounds can be used as the positive electrode active material of the battery of the present invention, but the scope of protection of the present invention is not limited to the scope of these examples. Examples 1-1, 1-2, 1-3 and 1-4 can demonstrate the correctness of the principles of the present invention to those skilled in the art.

Embodiment 1-1

[0090] Take LiMn 2 o 4 Be positive active material, according to the ratio of positive active material 90%: conductive carbon black 6%: binding agent SBR (styrene-butadiene rubber latex) 2%: thickener CMC (sodium carboxymethyl cellulose) 2%, first put Mix CMC with a certain amount of water evenly, then add active material and conductive carbon black, stir for 2 hours, and finally add SBR and stir for 10 minutes to obtain positive electrode slurry. The positive electrode current collector is a graphite plate with a thickness of 1 mm. The positive electrode slurry is evenly coated on the positive electrode current collector, and dried at 120 degrees for 12 hours to form a positive electrode sheet. The negative electrode of the battery is copper-plated tin foil, wherein the thickness of the copper foil is 0.1mm, and the thickness of the tin-plated layer is 0.005mm-0.01mm. The electrolyte is an aqueous solution containing 4mol / L zinc chloride and 1mol / L lithium chloride, and the...

Embodiment 1-2

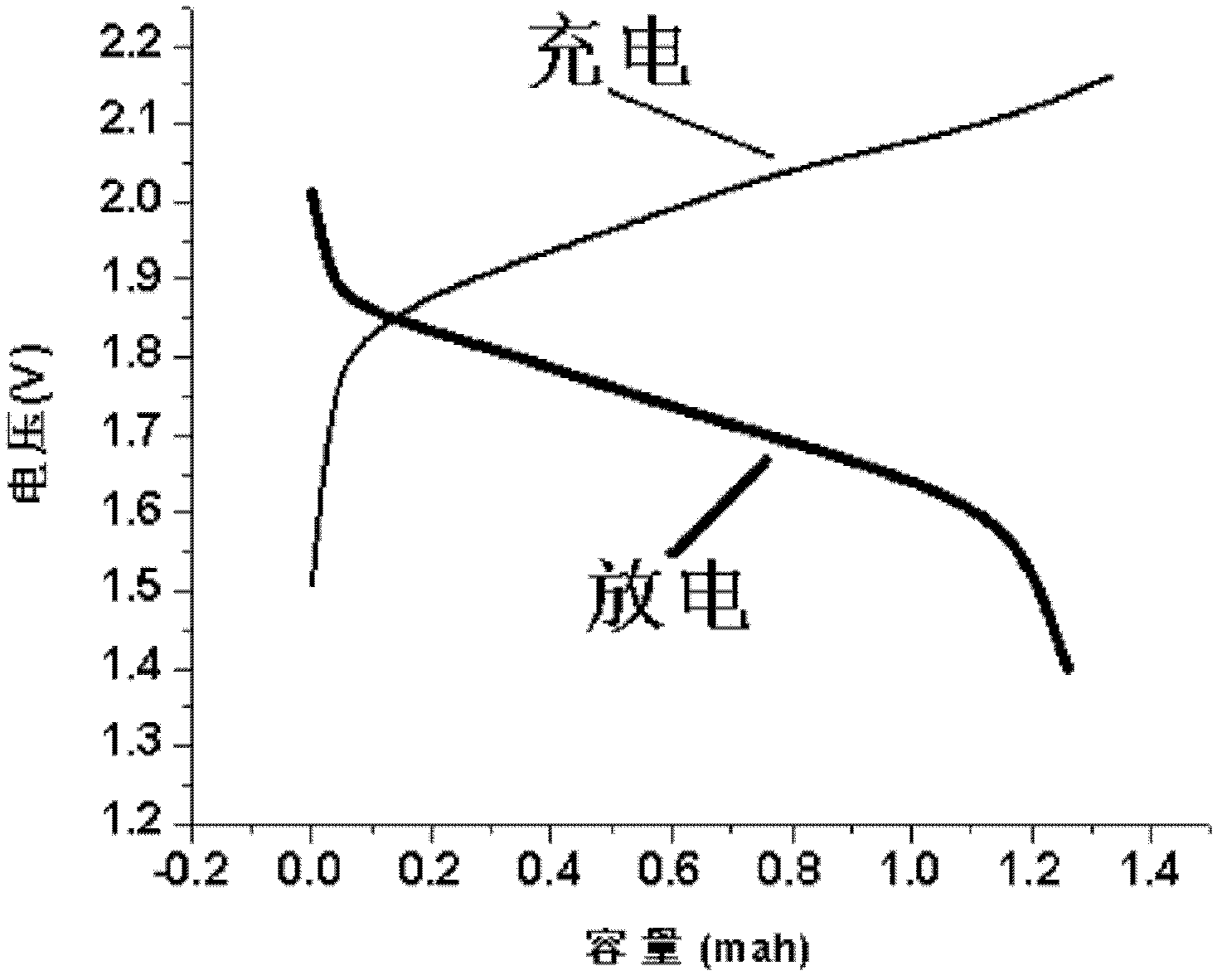

[0092] The battery is manufactured in the same manner as in Example 1-1, except that LiFePO 4 Replace LiMn 2 o 4 As the positive electrode active material, the difference from Example 1-1 is that the cycle operating voltage range of the battery is 0.8-2V. Its battery cycle performance test results are attached Figure 5 , 6 . Different from Example 1-1, the voltage platform of the battery is relatively low, and the discharge platform is about 1.2V, but the cycle performance is better, and there is almost no attenuation in 100 cycles. Although LiFePO 4 Replace LiMn 2 o 4 This leads to a lower platform, resulting in lower energy density, but the battery has better cycle performance than the latter.

[0093] In the same way, LiMnPO with olivine structure 4 Or materials with similar structures can replace the positive electrode active material in the present invention to form the battery described in the present invention, which cannot deviate from the spirit of the prese...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness range | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com