Rapid emergency treatment method of methyl mercaptan odor

A treatment method, a technology of methyl mercaptan, applied in separation methods, chemical instruments and methods, and separation of dispersed particles, can solve the problems of long cycle, cumbersome reaction process, complex equipment, etc., and achieve mild reaction conditions, convenient transportation, good processing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

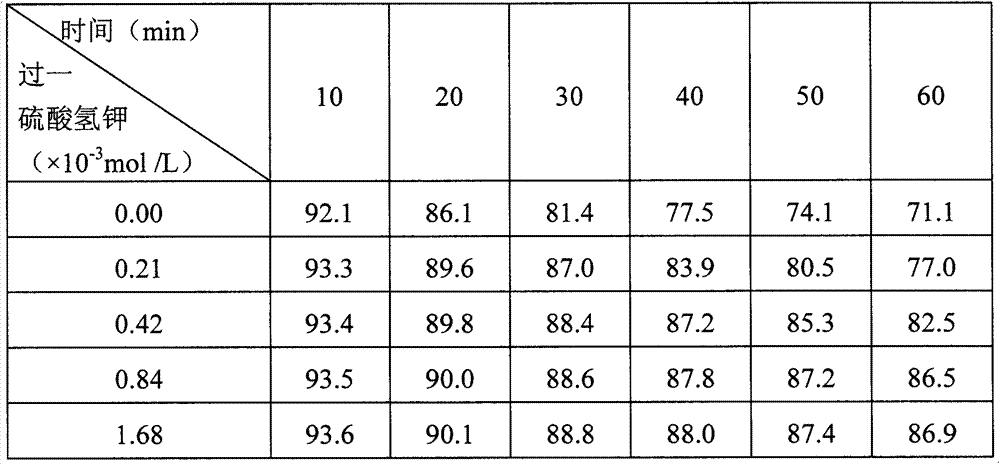

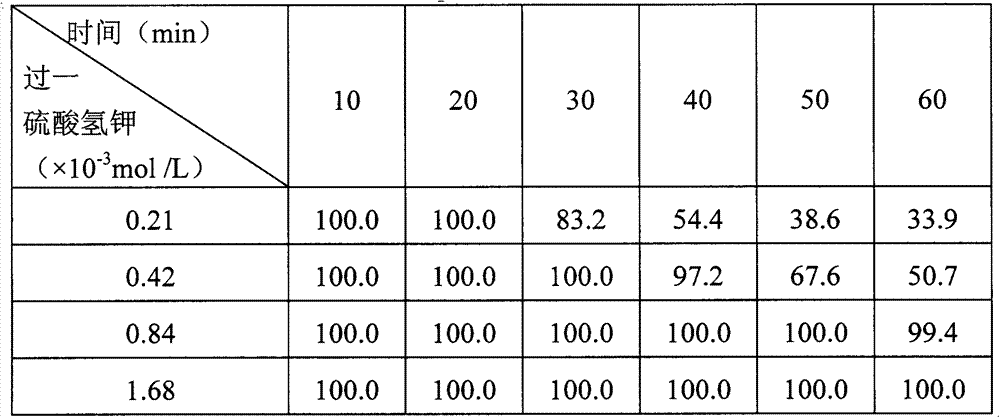

[0013] The details are as follows: prepare potassium persulfate containing different concentrations (0mol / L, 0.21×10 -3 mol / L, 0.42×10 -3 mol / L, 0.84×10 -3 mol / L, 1.68×10 -3 mol / L) of pH=12 of 500mL sodium hydroxide lye; the intake of air keeps 1.5L / min, the intake of methylmercaptan keeps 40mL / min, and the concentration of methylmercaptan gas after mixing is 80ppm; The showering intensity is 120mL / min; the concentration of methyl mercaptan in the water sample and the concentration of methyl mercaptan in the tail gas are sampled every 10 minutes, and the removal rate of methyl mercaptan in the whole system and the removal rate of methyl mercaptan absorbed in the solution are calculated respectively;

[0014] The concentration of methyl mercaptan in the tail gas is directly detected by a methyl mercaptan detector;

[0015] The methyl mercaptan in the solution is detected by spectrophotometry: the reaction between methyl mercaptan and Ellman reagent produces a yellow product,...

Embodiment 2

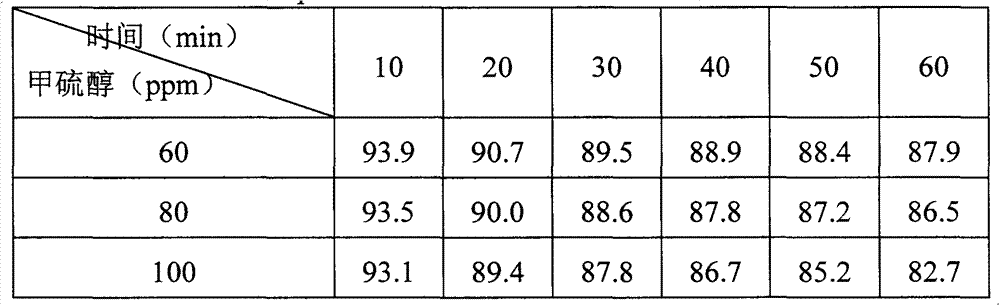

[0025] Prepare 500mL of sodium hydroxide lye with pH=12 containing potassium peroxomonosulfate, the concentration of potassium peroxymonosulfate is 0.84×10 -3 mol / L. The intake of air is maintained at 1.5L / min, and the intake of methyl mercaptan is changed to maintain 30mL / min, 40mL / min, and 50mL / min respectively, and the concentration of mixed methyl mercaptan gas is 60ppm, 80ppm, and 100ppm respectively; spray The intensity is 120mL / min; samples are taken every 10 minutes to detect the concentration of methyl mercaptan in the water sample, and the removal rate is calculated.

[0026] result:

[0027] Table 2-1. Potassium monoperoxymonosulfate to the removal rate (%) of different concentrations of methyl mercaptan in the system under the condition of pH=12

[0028]

[0029] The results show that at 0.84×10 -3 When mol / L of potassium hydrogen persulfate, the removal rate of methyl mercaptan in the whole system increases with the decrease of the concentration.

[0030] T...

Embodiment 3

[0034] Prepare 500mL of sodium hydroxide lye with pH=12 containing potassium peroxomonosulfate, the concentration of potassium peroxymonosulfate is 0.84×10 -3 mol / L. The intake of air is kept at 1.5L / min, the intake of methyl mercaptan is kept at 50mL / min, the concentration of methyl mercaptan gas after mixing is 100ppm respectively; the spray intensity is 120mL / min; samples are taken every 10min to detect formazan in water samples The concentration of mercaptans was used to calculate the removal rate.

[0035] This example is to carry out continuous addition experiment, add potassium bisulfate (0.84 × 10 -3 mol) and sodium hydroxide (10 -2 mol).

[0036] result:

[0037] Table 3. Continuous addition of potassium hydrogen persulfate to the removal rate (%) of methyl mercaptan odor in the system

[0038] time (min)

[0039] The result shows that when there is potassium hydrogen persulfate in the solution, the methylmercaptan concentration removal rate reaches 100...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com