High-ammonia nitrogen organic sewage purification treatment system and method

A technology for organic sewage and purification treatment, applied in water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve problems such as high operating costs, insufficient land carrying capacity, secondary pollution, etc. , to achieve the effect of improving the efficiency of sewage purification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Sewage from the manure treatment project of the scientific research base of the Sichuan Provincial Academy of Animal Husbandry Science in Shipan Town, Jianyang City, Sichuan Province. After measurement, the sewage discharge volume is 40m 3 / d, after anaerobic digestion, the treated raw water index and birth index are shown in Table 1.

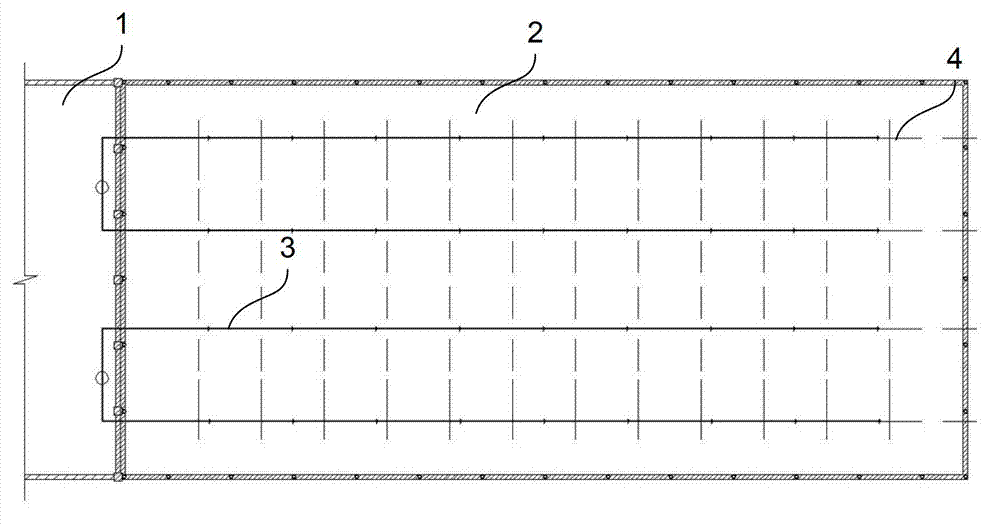

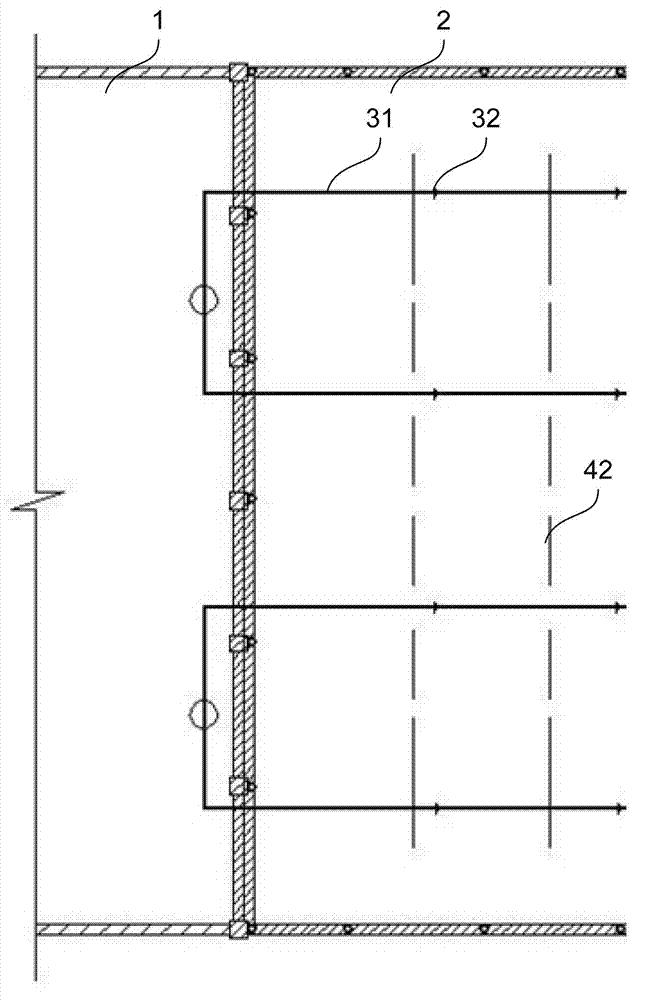

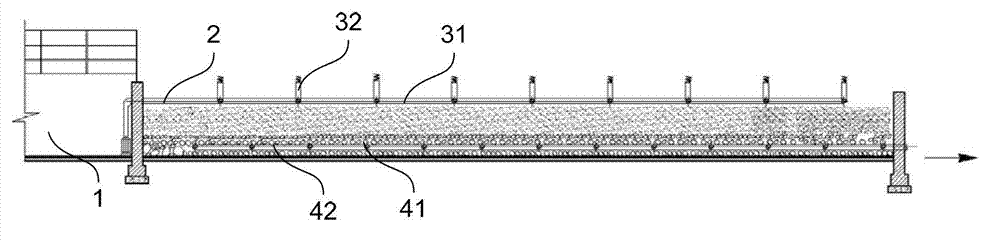

[0025] Specific as figure 1 , figure 2 As shown, build a high ammonia nitrogen organic sewage purification treatment system. The design hydraulic load is 0.06m / d, and the daily sewage treatment capacity is 40m 3 . The effective cross-sectional area of the mineral filter pool in the purification treatment system is designed to be 670m 2 , using brick-concrete and low-pressure polyethylene (HDPE) anti-seepage membrane construction. Mineral filter pools can also be constructed of concrete.

[0026] figure 1 It is a schematic plan view of the high ammonia nitrogen organic sewage purification treatment system; figure 2 yes figure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com