Preparation method of poly-p-aminobenzoylamonoundecylamine

A technology of aminobenzamide and poly-pair, which is applied in the field of synthesis of polymer materials and can solve the problems of difficult synthesis of PA11T

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

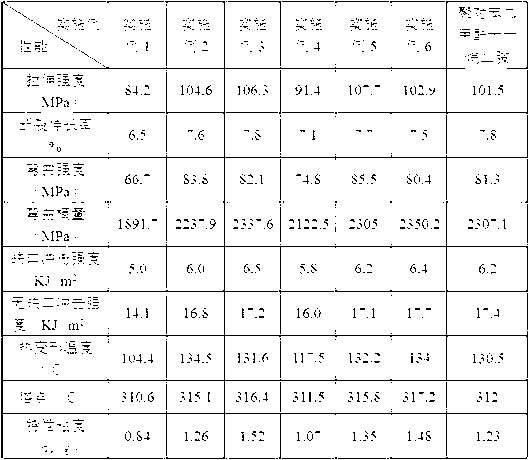

Examples

Embodiment 1

[0032] Example 1 (10 grams per serving)

[0033] The preparation method of poly-p-aminobenzamide undecylamine, its preparation steps are:

[0034] (1) Salt formation: Mix 200 grams of aminoundecanoic acid, 140 grams of p-aminobenzoic acid, 1500 grams of distilled water, and 2 grams of phosphoric acid, stir well, and react at 120 ° C for 3 hours; then filter and wash , dried in vacuum to obtain PA11T salt;

[0035] (2) Adding materials: PA11T salt, distilled water with the same weight as PA11T salt, 0.6% (w / w) acetic acid for PA11T salt, stir evenly to obtain a mixture;

[0036] (3) Reaction synthesis: the mixture is heated up to 270°C in a helium atmosphere, pressurized to 3MPa, and kept at a constant pressure for 2h; then lowered to normal pressure for 2h, raised to 320°C while lowering to normal pressure, and kept for 2h; finally pumped Vacuum to -0.095MPa, keep the temperature and pressure for 1h, and discharge to obtain PA11T.

[0037] The preparation steps are carried...

Embodiment 2

[0039] Example 2 (20 grams per serving)

[0040] The preparation method of poly-p-aminobenzamide undecylamine, its preparation steps are:

[0041] (1) Salt formation: Mix 400 grams of aminoundecanoic acid, 280 grams of p-aminobenzoic acid, 3000 grams of distilled water, and 4 grams of sodium phosphate, stir well, and react at 120 °C for 3 hours; then filter with suction, Washing, vacuum drying, to obtain PA11T salt;

[0042] (2) Adding materials: PA11T salt, methanol with the same weight as PA11T salt, and 1.2% (w / w) butylamine for PA11T salt are stirred evenly to obtain a mixture;

[0043] (3) Reaction synthesis: the mixture was heated up to 280°C in an argon atmosphere, pressurized to 2.5MPa, kept at a constant pressure for 2 hours; then lowered to normal pressure for 2 hours, raised to 310°C while lowering to normal pressure, and kept for 2 hours; finally Vacuumize to -0.095MPa, keep the temperature and pressure for 1h, and discharge the material to obtain PA11T.

[00...

Embodiment 3

[0045] Example 3 (15 grams per serving)

[0046]The preparation method of poly-p-aminobenzamide undecylamine, its preparation steps are:

[0047] (1) Salt formation: Mix 300 grams of aminoundecanoic acid, 210 grams of p-aminobenzoic acid, 2250 grams of distilled water, and 3 grams of phosphorous acid, stir well, and react at 120°C for 3 hours; then filter with suction, Washing and vacuum drying to obtain PA11T salt;

[0048] (2) Adding: Mix PA11T salt, ethanol with the same weight as PA11T salt, and 1.0% (w / w) lauric acid for PA11T salt, and stir evenly to obtain a mixture;

[0049] (3) Reaction synthesis: the mixture was heated up to 290°C in a nitrogen atmosphere, pressurized to 2.7MPa, kept at a constant pressure for 2 hours; then lowered to normal pressure for 2 hours, raised to 330°C while lowering to normal pressure, and kept for 2 hours; finally pumped Vacuum to -0.095MPa, keep the temperature and pressure for 1h, and discharge to obtain PA11T.

[0050] The perform...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com