Yeast essence extract and preparation method thereof

A technology of yeast extract and yeast extract, which is applied in the field of yeast extract and its preparation, can solve the problems that yeast extract is easy to precipitate and does not meet the application in the field of cosmetics, so as to achieve non-degeneration precipitation, enhance skin immune function, and improve skin resistance. Effects of Free Radical Capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

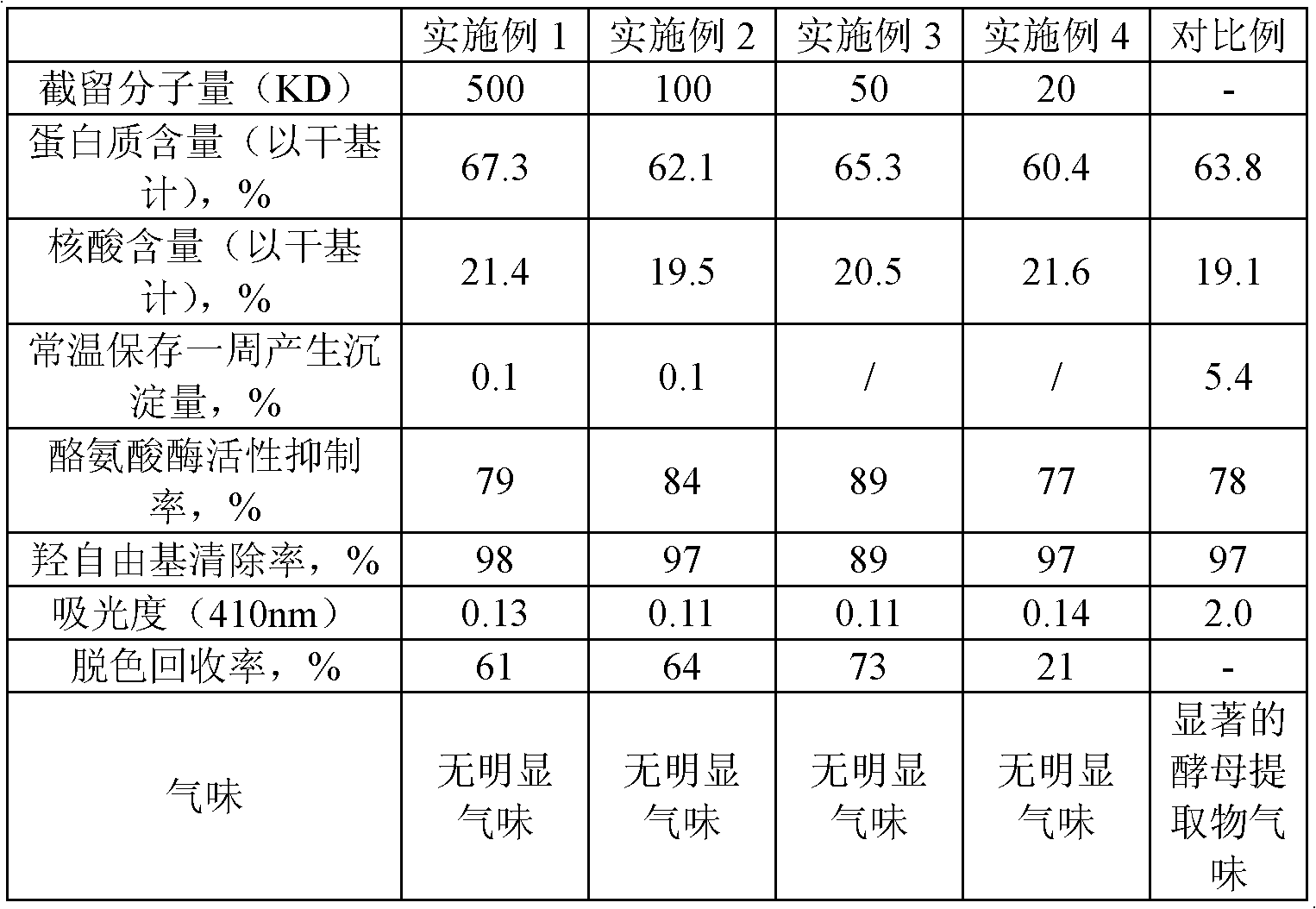

[0020] According to a typical implementation of the present invention, when the dry matter mass percentage is 5%, the absorbance of the yeast extract at a wavelength of 410nm is lower than 0.15, which ensures that the color of the yeast extract is close to colorless , Odorless, suitable for coloring and seasoning of cosmetics, has the advantages of strong applicability and wide application fields.

[0021] The present invention also provides a method for preparing the above-mentioned yeast extract. According to a typical embodiment of the present invention, the preparation method includes the following steps: 1) preparing the yeast extract; 2) membrane separation, and preparing the yeast extract into an aqueous solution with a mass percentage of dry matter of 2% to 20%, and then use an ultrafiltration membrane with a molecular weight cut-off of 20 to 500KD to separate and collect the supernatant; 3) high-temperature treatment, the supernatant is heated to 80- 120°C, keep it fo...

Embodiment 1

[0027] 1) Prepare yeast extract. The yeast was prepared into a 10% suspension by adding water according to the mass ratio, heated at 60°C for 5 hours, adjusted to pH 6.0, added 0.5% papain, reacted for 15 hours, heated to 90°C for 1.5h, and collected the supernatant by centrifugation. Evaporate to dryness to obtain yeast extract.

[0028] 2) Membrane separation. Take 100 kg of yeast extract and add purified water to prepare 1 ton of solution, use a ceramic membrane with a molecular weight cut-off of 500KD for membrane separation, collect and pass through the supernatant to obtain a supernatant with a dry matter of 4.1%.

[0029] 3) High temperature treatment. The supernatant was concentrated in vacuo to a dry matter of 10.2%, and incubated at 100° C. for 1 h.

[0030] 4) Decolorization. The supernatant was adjusted to pH 4.0 with hydrochloric acid, and the temperature was adjusted to 20°C. It was decolorized through a macroporous adsorption resin column, and the decolorize...

Embodiment 2

[0033] 1) Prepare yeast extract. The yeast was prepared into a 10% suspension by adding water according to the mass ratio, heated at 60°C for 5 hours, adjusted to pH 6.0, added 0.5% papain, reacted for 15 hours, heated to 90°C for 1.5h, and collected the supernatant by centrifugation. Evaporate to dryness to obtain yeast extract.

[0034] 2) Membrane separation. Take 50 kg of yeast extract and add purified water to prepare 1 ton of solution, use a ceramic membrane with a molecular weight cut-off of 100KD for membrane separation, collect and pass through the supernatant to obtain a supernatant with a dry matter of 3.2%.

[0035] 3) High temperature treatment. The supernatant was concentrated in vacuo to a dry matter of 8.2%, and treated at 120° C. for 0.5 h.

[0036] 4) Decolorization. The supernatant was adjusted to pH 5.0 with hydrochloric acid, and the temperature was adjusted to 50°C. It was decolorized through a macroporous adsorption resin column, and the decolorized so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com