Composition capable of curing abnormal blood lipid

A technology for dyslipidemia and a composition is applied in the field of medical compositions for the treatment of dyslipidemia, which can solve the problems of unsatisfactory, unsatisfactory safety, unmaximized lipid-lowering effect, etc., and can increase HDL-C and improve blood lipids The effect of reaching the target rate and serum uric acid has no effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

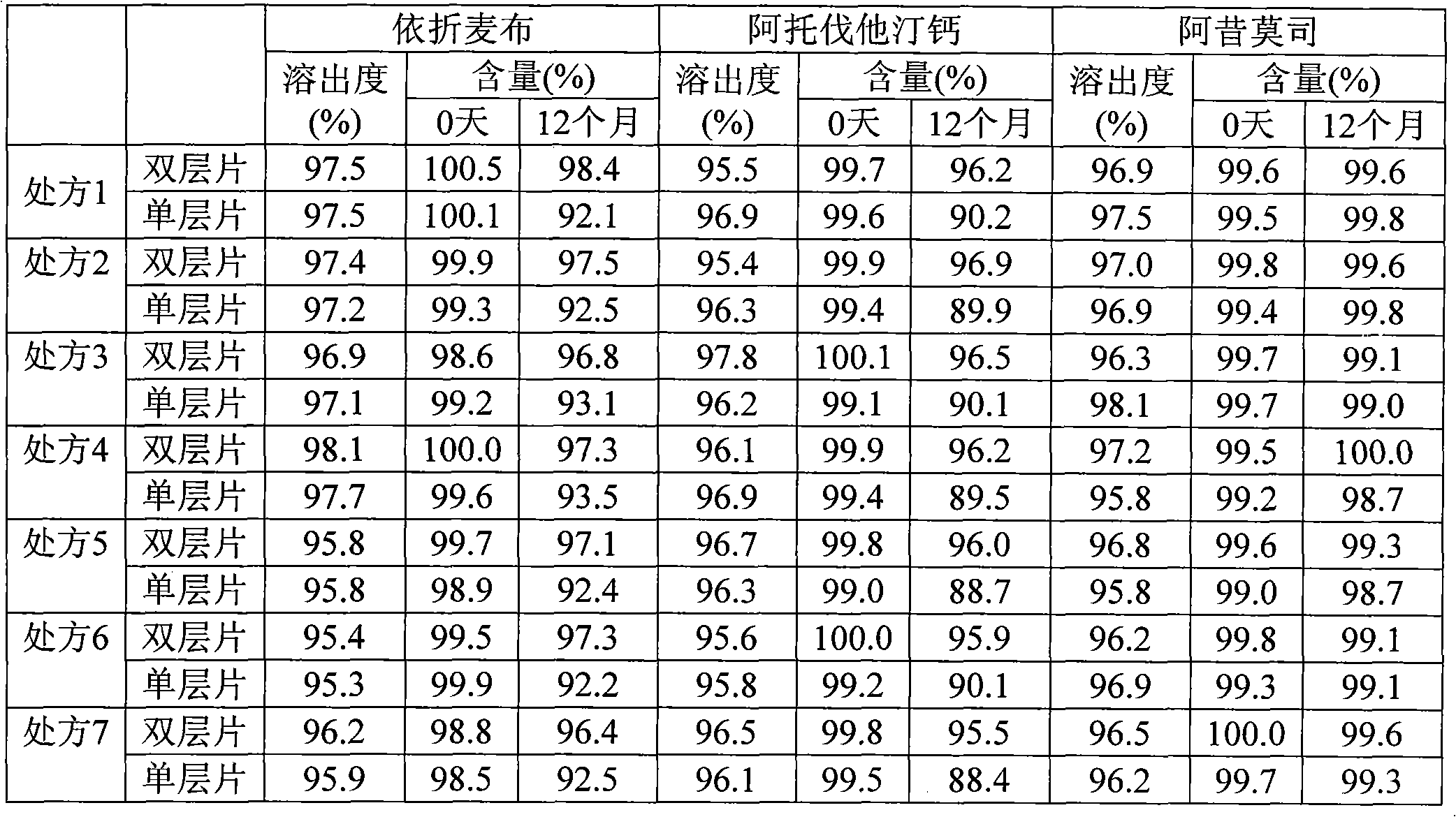

[0074] Example 1 tablet

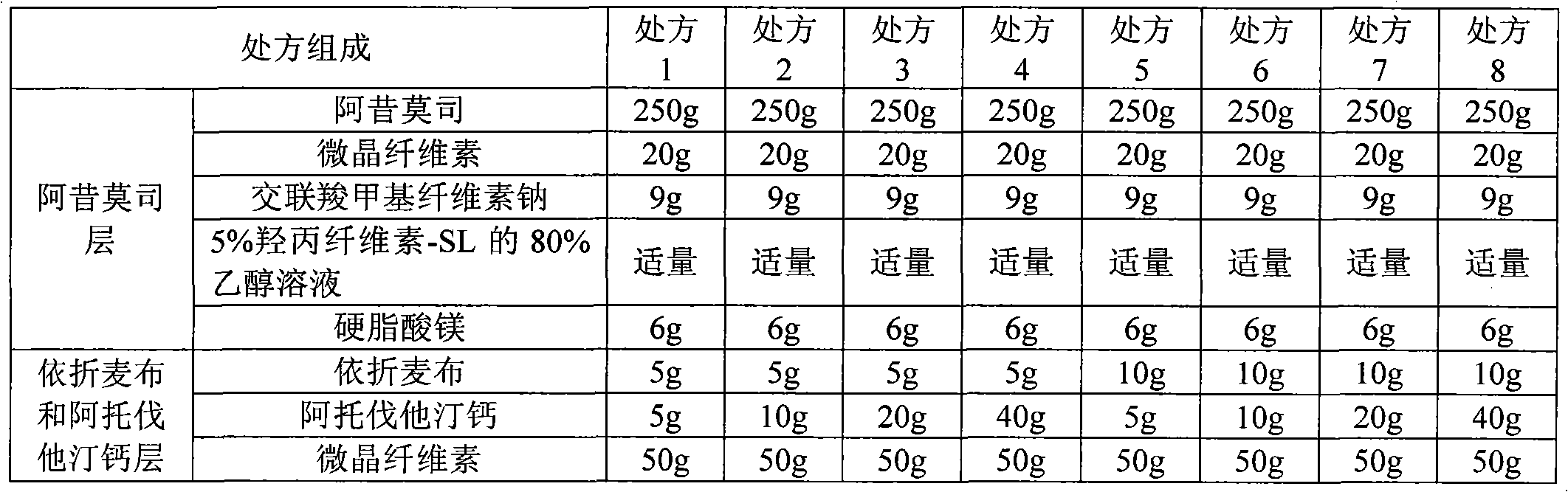

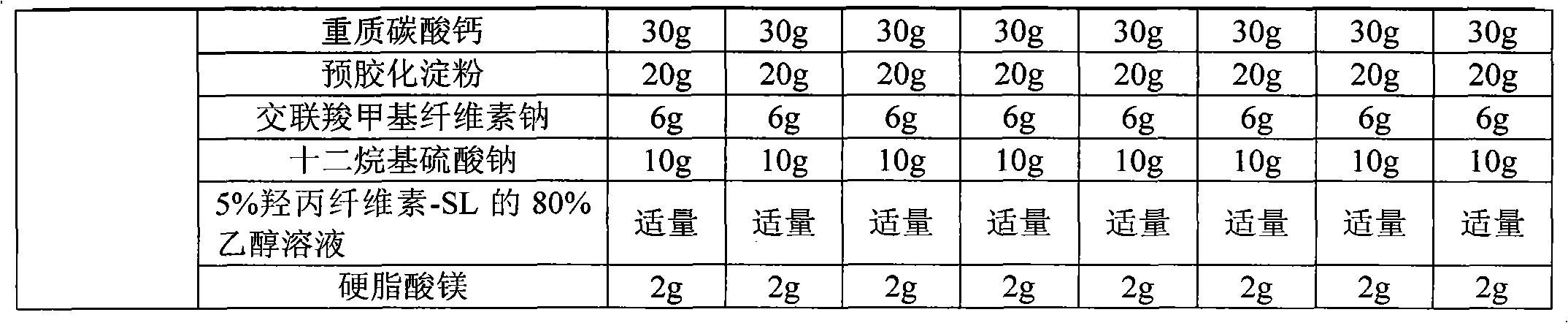

[0075] 1. Prescription (based on 1000 tablets)

[0076]

[0077]

[0078] 2. Preparation process

[0079] (1) Grind acipimox, ezetimibe, and atorvastatin calcium through a 100-mesh sieve for later use.

[0080] (2) Mix acipimox, microcrystalline cellulose, and croscarmellose sodium in a wet granulator according to the prescription amount, stir at 600 rpm, and shear at 1200 rpm for about 10 minutes.

[0081] (3) Add an appropriate amount of 80% ethanol solution of 5% hydroxypropyl cellulose-SL to prepare a soft material, stir at 500 rpm, and shear at 1380 rpm for about 3 minutes.

[0082] (4) Granulate with a 24-mesh sieve, dry at 40° C., and then granulate with a 24-mesh sieve to obtain partial granules of acipimox.

[0083] (5) Ezetimibe, microcrystalline cellulose, heavy calcium carbonate, pregelatinized starch, croscarmellose sodium, and sodium lauryl sulfate are mixed in a wet granulator and stirred at 600 rpm Min, shear 1200 rpm, about ...

Embodiment 2

[0107] Example 2 tablet

[0108] 1. Prescription (based on 1000 tablets)

[0109]

[0110]

[0111] 2. Preparation process

[0112] (1) Grind acipimox, ezetimibe, and atorvastatin calcium through a 100-mesh sieve for later use.

[0113] (2) Mix acipimox, microcrystalline cellulose, and croscarmellose sodium in a wet granulator according to the prescription amount, stir at 600 rpm, and shear at 1200 rpm for about 10 minutes.

[0114] (3) Add an appropriate amount of 80% ethanol solution of 5% hydroxypropyl cellulose-SL to prepare a soft material, stir at 500 rpm, and shear at 1380 rpm for about 3 minutes.

[0115] (4) Granulate with a 24-mesh sieve, dry at 40°C, then granulate with a 24-mesh sieve, add magnesium stearate to obtain the granules of the acipimox part.

[0116] (5) Mix ezetimibe, microcrystalline cellulose, pregelatinized starch, croscarmellose sodium, and sodium lauryl sulfate in a wet granulator, stir at 600 rpm, and shear 1200 rpm, about 10 minutes.

...

Embodiment 3

[0137] Example 3 tablet

[0138] 1. Prescription (based on 1000 tablets)

[0139]

[0140]

[0141] 2. Preparation process

[0142] (1) Grind acipimox, ezetimibe, and atorvastatin calcium through a 100-mesh sieve for later use.

[0143] (2) Mix acipimox, microcrystalline cellulose, and croscarmellose sodium in a wet granulator according to the prescription amount, stir at 600 rpm, and shear at 1200 rpm for about 10 minutes.

[0144] (3) Add an appropriate amount of 80% ethanol solution of 5% hydroxypropyl cellulose-SL to prepare a soft material, stir at 500 rpm, and shear at 1380 rpm for about 3 minutes.

[0145] (4) Granulate with a 24-mesh sieve, dry at 40° C., then granulate with a 24-mesh sieve, and add a prescribed amount of magnesium stearate to obtain granules of the acipimox part.

[0146] (5) Ezetimibe, microcrystalline cellulose, pregelatinized starch, croscarmellose sodium, and sodium lauryl sulfate are mixed in a wet granulator, stirred at 600 rpm, and she...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com