Bio-oil starch adhesive used for artificial board and preparation method

A starch adhesive and bio-oil technology, applied in adhesives, grafted polymer adhesives, oil/fat/wax adhesives, etc., can solve problems such as formaldehyde pollution, achieve high activity, reduce costs, and process stability Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

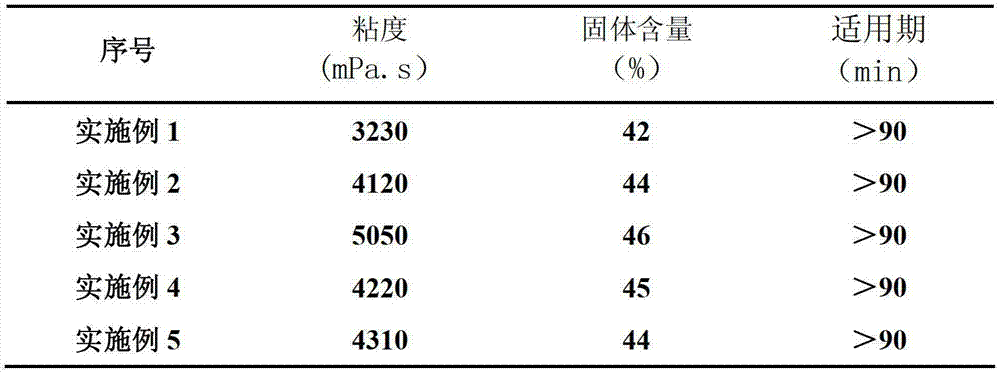

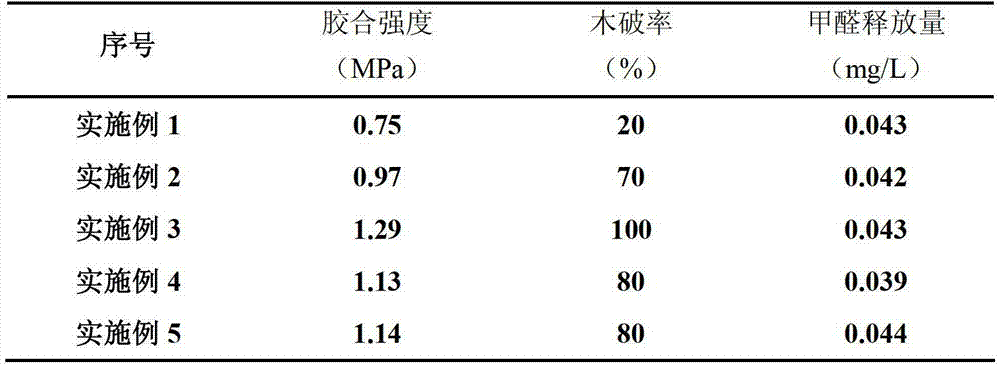

Examples

preparation example Construction

[0022] The preparation method of above-mentioned bio-oil starch adhesive that the present invention proposes comprises the following steps:

[0023] The first step: Take 150 parts of 0.4-0.6mol / L hydrochloric acid into the reaction vessel, then add 80-120 parts of starch to prepare starch emulsion; within 10 minutes, raise the temperature to 50-65°C and keep the temperature until the third step, add 0.8- 2.4 parts of an oxidizing agent with a mass fraction of 10% were reacted for 30-60 minutes to obtain a primary modified starch emulsion.

[0024] Step 2: Add 10-30 parts of polyvinyl alcohol solution with a mass fraction of 8% to the primary modified starch emulsion, neutralize part of the hydrochloric acid with a 10% mass fraction of sodium hydroxide solution, and adjust the pH value to 4-5.5 within 15 minutes; 60 minutes Add 10-30 parts of acrylamide in five batches (each batch is 1 / 5 of the total amount), and then react for 30-60 minutes; then add 0.2-0.6 parts of oxidant, ...

Embodiment 1

[0028]The mass parts of each raw material component in this embodiment are as follows: 80 parts of corn starch, 150 parts of hydrochloric acid, 1 part of ammonium persulfate oxidizing agent, 10 parts of polyvinyl alcohol stabilizer, 10 parts of acrylamide, 20 parts of bio-oil, glyoxal curing agent 10 parts, 5 parts of MDI curing agent, 20 parts of flour filler;

[0029] The preparation method of bio-oil starch adhesive comprises the following steps:

[0030] Step 1: Add 150 parts of 0.4mol / L hydrochloric acid into the reaction vessel, then add 80 parts of cornstarch to make starch emulsion; raise the temperature to 50°C within 10 minutes and keep the temperature until the third step, add 0.8 parts of 10% ammonium persulfate solution, and react for 30 minutes to obtain a modified starch emulsion.

[0031] Step 2: Add 10 parts of 8% 1750-type polyvinyl alcohol solution to the primary modified starch emulsion, neutralize part of the hydrochloric acid with 10% sodium hydroxide so...

Embodiment 2

[0035] The mass parts of each raw material component in this embodiment are as follows: 100 parts of tapioca starch, 150 parts of hydrochloric acid, 2 parts of potassium persulfate oxidizing agent, 20 parts of polyvinyl alcohol stabilizer, 20 parts of acrylamide, 30 parts of bio-oil, glutaraldehyde curing agent 20 parts, 10 parts of PMDI curing agent, 30 parts of light calcium carbonate filler;

[0036] The preparation method of bio-oil starch adhesive comprises the following steps:

[0037] Step 1: Add 150 parts of 0.5mol / L hydrochloric acid to the reaction vessel, then add 100 parts of tapioca starch to make starch emulsion; within 10 minutes, raise the temperature to 55°C and keep the temperature until the third step, add 1.6 parts of 10% cassava starch Potassium persulfate solution was reacted for 45 minutes to obtain a primary modified starch emulsion.

[0038] Step 2: Add 20 parts of 8% 1788 polyvinyl alcohol solution to the primary modified starch emulsion, neutralize ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com