Shield electro-hydraulic control system comprehensive test platform

A technology of electro-hydraulic control system and hydraulic control system, which is applied in the field of test platform, can solve the problems of system installation and debugging technology not fully mastered, and there is no database of design experience database and construction experience database of shield electro-hydraulic control system, so as to shorten the research and development Periodic, full-featured, high-simulation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

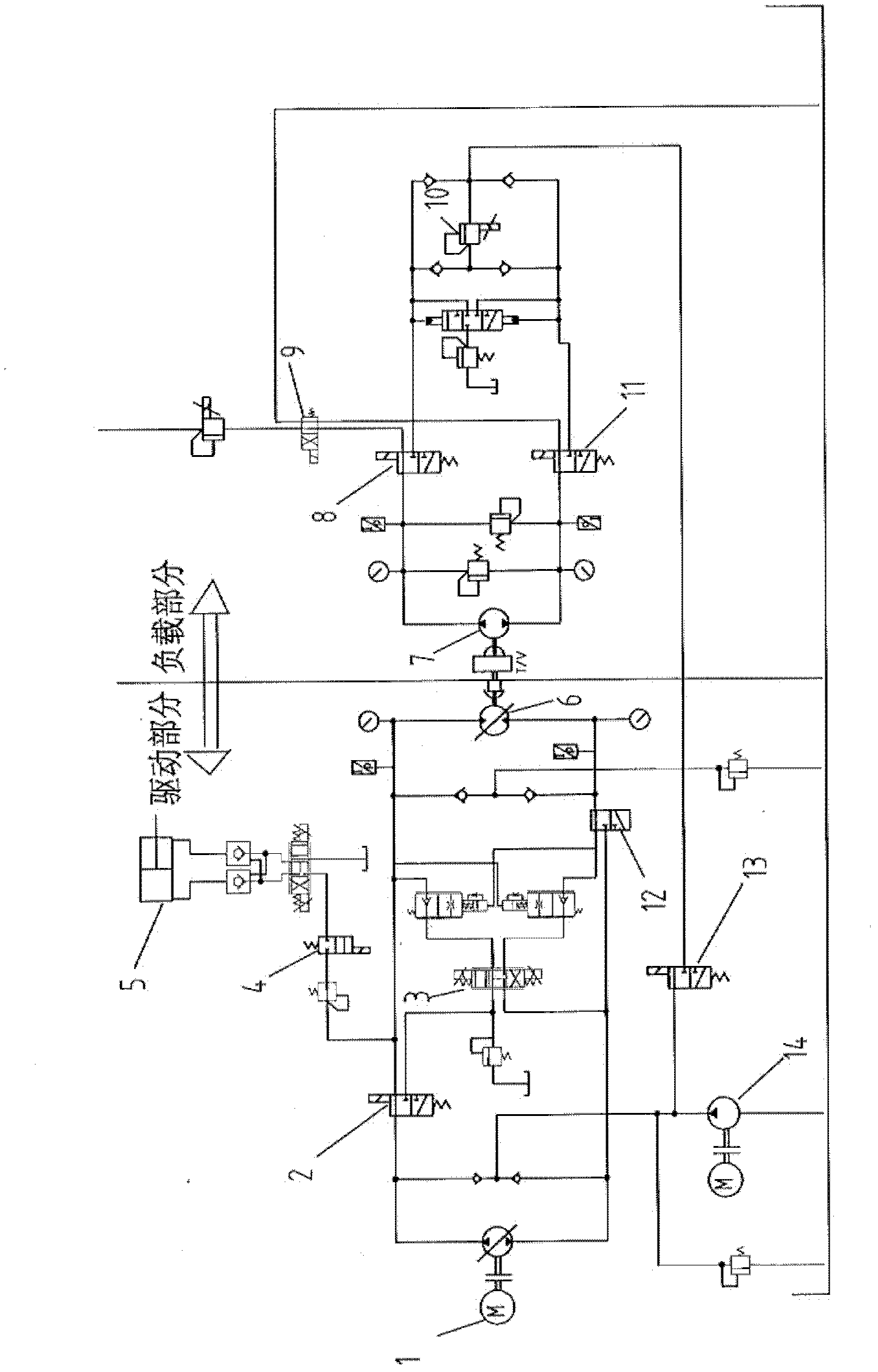

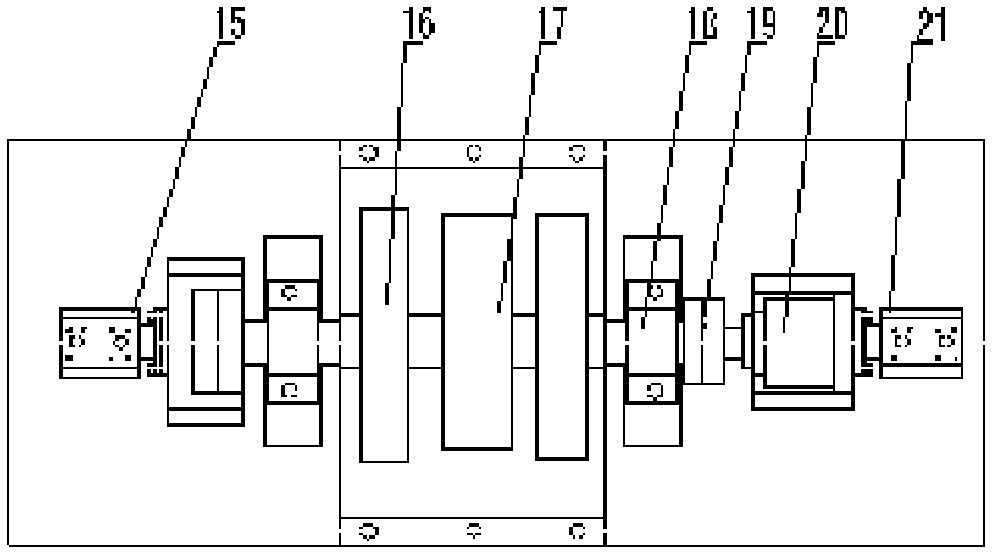

[0041] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. In this embodiment, a simulation test is carried out on the cutter head\segment assembly machine\screw conveyor load simulation and drive test unit of the shield electro-hydraulic comprehensive test platform.

[0042] When carrying out the cutter head drive simulation test, the electromagnets of the two-position three-way reversing valve 2 and the two-position three-way reversing valve 12 are energized, and the electromagnets of the two-position three-way reversing valve 4 are de-energized. The driving part is composed of a variable pump control motor system. By changing the displacement of the variable pump, the speed of the cutter head can be changed, and the speed regulation test of the cutter head is carried out. In the load simulation part on the right, the inertia load of the cutter head is simulated by the fixed inertia wheel 17 and the movable iner...

Embodiment 2

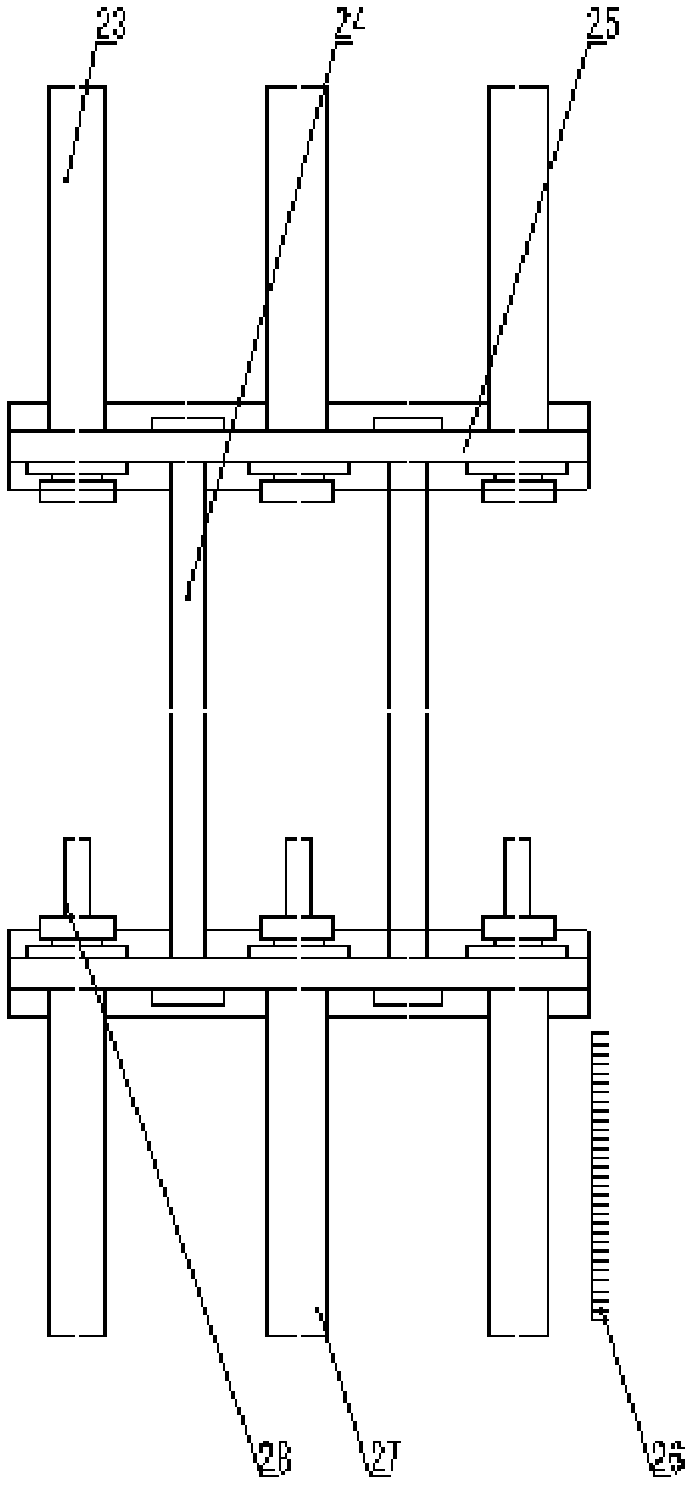

[0046] In this embodiment, a simulation test is carried out on the propulsion control system of the shield electro-hydraulic comprehensive test platform.

[0047] The propulsion hydraulic cylinder 27 and the loading hydraulic cylinder 23 of the simulated propulsion control system adopt a top-to-top configuration; there are two control modes for the output force and propulsion speed of the propulsion hydraulic cylinder: proportional pressure reducing valve control mode and proportional relief valve + proportional speed regulating valve control Mode, two different control modes can be switched through the two-position three-way reversing valve. It can complete the performance comparison test of two typical propulsion systems and the experimental research on the disturbance law of switching between two propulsion modes.

[0048] There are 4 groups of hydraulic cylinders in the whole system, and the pressure and flow of each group of hydraulic cylinders are independently controlle...

Embodiment 3

[0050] In this embodiment, a simulation test is carried out on the hydraulic cylinder motion control test system of the multi-degree-of-freedom segment assembly mechanism of the shield electro-hydraulic comprehensive test platform.

[0051] The multi-degree-of-freedom segment assembly mechanism hydraulic cylinder motion control test system is used to simulate the hydraulic cylinder motion control of the shield segment assembly machine. The system mainly consists of two vertical lifting hydraulic cylinders 32 and one horizontal moving hydraulic cylinder 31 and proportional directional valves controlling them. The flow and direction of the hydraulic cylinder can be controlled by the proportional directional valve, and the speed and direction of the hydraulic cylinder can be controlled. At the same time, each hydraulic cylinder is equipped with a displacement sensor 33, which can monitor the displacement of the hydraulic cylinder in real time and feed back the measured displacemen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com