Calcitriol solution and preparation method thereof

A technology of calcitriol and solution, which is applied in bone diseases, pharmaceutical formulations, medical preparations of non-active ingredients, etc., can solve the problems of low bioavailability, poor stability of soft capsules and capsules, and monotonous dosage forms And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0023] Embodiment 1 calcitriol solution

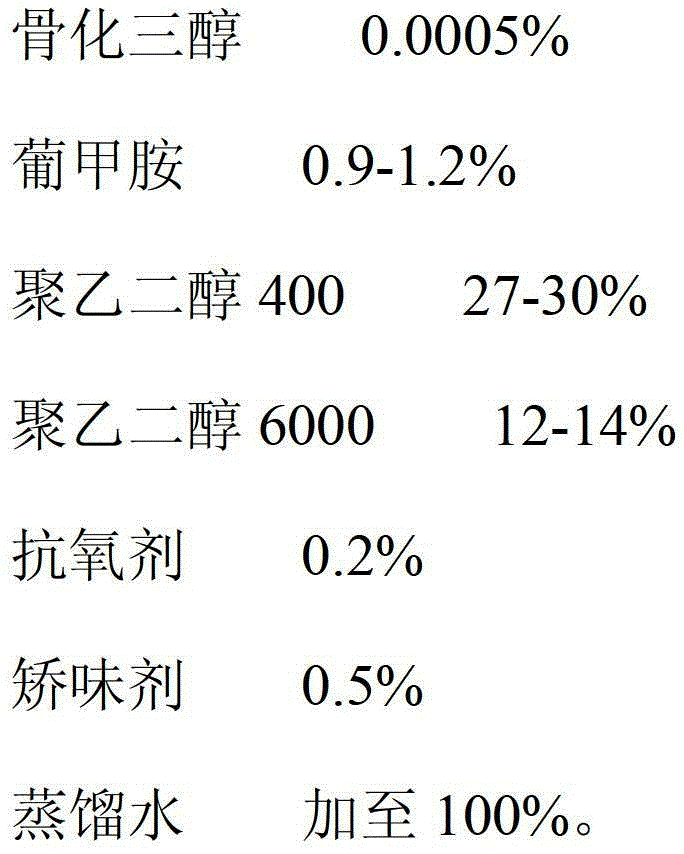

[0024] The prescription is:

[0025]

[0026] The preparation method is:

[0027] 1) Weigh 80% of the prescribed amount of distilled water, add the prescribed amount of polyethylene glycol 400, and stir evenly; continue to add the prescribed amount of meglumine and polyethylene glycol 6000, and stir at 55°C for 25 minutes until completely dissolved;

[0028] 2) Raise the temperature to 70°C, add the prescribed amount of calcitriol at a stirring speed of 1000rpm, and continue stirring for 40 minutes until it is completely dissolved;

[0029] 3) Add distilled water to the full amount, add the prescribed amount of sodium sulfite and aspartame, stir to dissolve; test at room temperature, after passing the test, stir and fill, then label, pack, sample, and store.

Embodiment 2

[0030] Embodiment 2 calcitriol solution

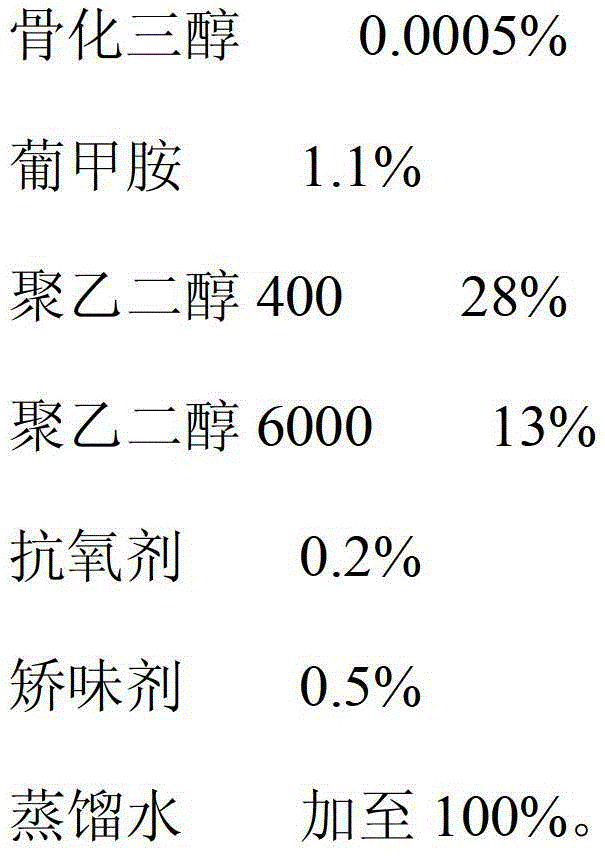

[0031] The prescription is:

[0032]

[0033]

[0034] The preparation method is:

[0035] 1) Weigh 70% of the prescribed amount of distilled water, add the prescribed amount of polyethylene glycol 400, and stir evenly; continue to add the prescribed amount of meglumine and polyethylene glycol 6000, and stir at 45°C for 15 minutes until completely dissolved;

[0036] 2) Raise the temperature to 60°C, add the prescribed amount of calcitriol at a stirring speed of 500rpm, and continue stirring for 20 minutes until it is completely dissolved;

[0037] 3) Add distilled water to the full amount, add the prescribed amount of sodium bisulfite and sucrose, stir to dissolve; test at room temperature, after passing the test, stir and fill, then label, pack, sample, and store.

Embodiment 3

[0038] Embodiment 3 calcitriol solution

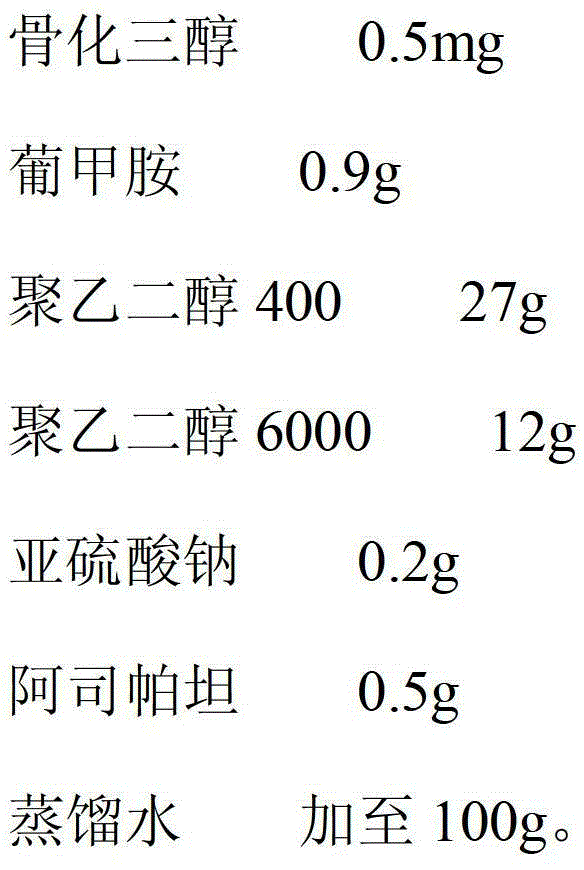

[0039] The prescription is:

[0040]

[0041] The preparation method is:

[0042] 1) Weigh 75% of the prescribed amount of distilled water, add the prescribed amount of polyethylene glycol 400, and stir evenly; continue to add the prescribed amount of meglumine and polyethylene glycol 6000, and stir at 50°C for 20 minutes until completely dissolved;

[0043] 2) Raise the temperature to 65°C, add the prescribed amount of calcitriol at a stirring speed of 800rpm, and continue stirring for 30 minutes until it is completely dissolved;

[0044] 3) Add distilled water to the full amount, add the prescribed amount of sodium metabisulfite and stevioside, stir to dissolve; test at room temperature, after passing the test, stir and fill, then label, pack, sample and store.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com