Calcium and magnesium separation method for dolomite carbonization process and application thereof

A separation method and dolomite technology, applied in the direction of magnesium carbonate, calcium carbonate/strontium/barium, etc., can solve the problems of high equipment requirements, expensive additives, complicated secondary carbonization process, etc., and achieve the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

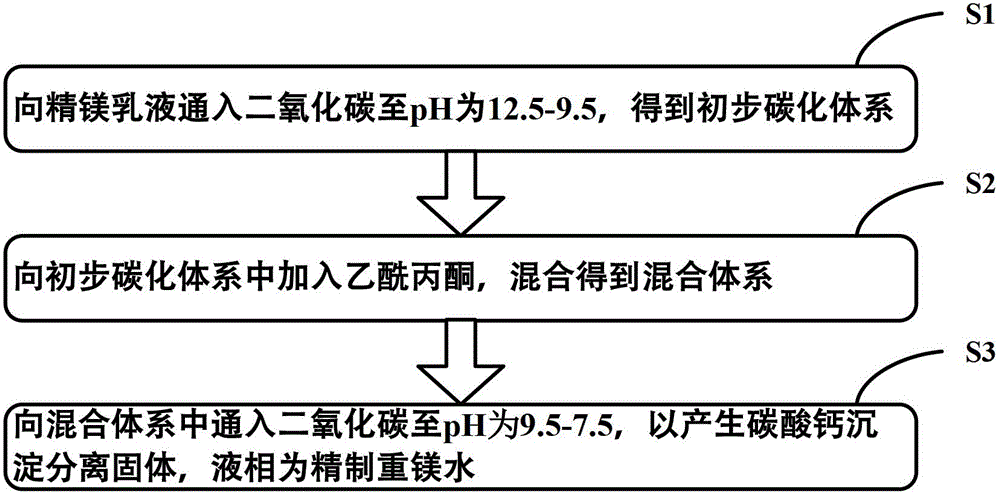

Method used

Image

Examples

preparation example Construction

[0019] The preparation of refined magnesium emulsion can adopt the routine treatment method known to those skilled in the art to carry out. Specifically, for example, the dolomite can be mechanically crushed to a size of 1-10 cm with a crusher first, and generally can be relatively uniform particles of about 2-5 cm. Then it is calcined at 850-1100°C to become calcined white. The calcination temperature and calcination time can be selected and determined by those skilled in the art according to specific conditions, for example, calcination can be performed at 900-1000° C. for 0.5-5 hours, or 1-3 hours. Digestion refers to mixing calcined white with water to make pulp, which can be properly heated and supplemented with stirring to promote digestion. Specific digestion conditions can also be selected and determined by those skilled in the art according to actual conditions. For example, the mass ratio of water to calcined white may be in the range of 30-70:1. The digestion sol...

Embodiment 1

[0042] Inject CO into the refined magnesium emulsion at room temperature 2 , CO 2 The flow rate is 0.5L / min, and the pH of the refined magnesium emulsion is tracked and tested. The initial pH is 13.0; when the pH of the system reaches 12.5, add acetylacetone, and the concentration of acetylacetone in the system is 0.003mol / L; shake well and continue carbonization until the pH of the system is 8.5, then carry out suction filtration and separation, and the filter residue is light Calcium carbonate, the filtrate is the refined heavy magnesium water, which is reserved for the next step. The calcium-magnesium ratio of the refined heavy magnesium water is 1:150.

[0043] Continue to feed carbon dioxide into the refined heavy magnesium water until the pH of the system is 6.9. After pyrolysis, suction filtration, and drying, high-purity basic magnesium carbonate is obtained. The chemical composition and content of basic magnesium carbonate are: MgO-42.27%, CaO-0.40%, Fe-0.02%, reac...

Embodiment 2

[0045] Inject CO into the refined magnesium emulsion at room temperature 2 , CO 2 The flow rate is 0.5L / min, and the pH of the refined magnesium emulsion is tracked and tested. The initial pH is 12.78; when the pH of the system reaches 10, add acetylacetone, and the concentration of acetylacetone in the system is 0.006mol / L; shake well and continue carbonization until the pH of the system is 7.5, then carry out suction filtration and separation, and the filter residue is light Calcium carbonate, the filtrate is the refined heavy magnesium water, which is reserved for the next step. The calcium-magnesium ratio of the refined heavy magnesium water is 1:235.

[0046] Continue to feed carbon dioxide into the refined heavy magnesium water until the pH of the system is 7.0. After pyrolysis, suction filtration, and drying, high-purity basic magnesium carbonate is obtained. The chemical composition and content of basic magnesium carbonate are: MgO-41.30%, CaO-0.375%, Fe-0.009%, rea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com