Reaction extrusion polymerization method of functional acrylate resin

A technology of acrylates and acrylic resins, which is applied in the field of preparation of functional polymer compounds, can solve problems such as the inability to rapidly cool and terminate polymerization, the impossibility of obtaining industrialized products, and the impossibility of implementation, achieving solvent-free recovery, transparency and Excellent mechanical properties and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

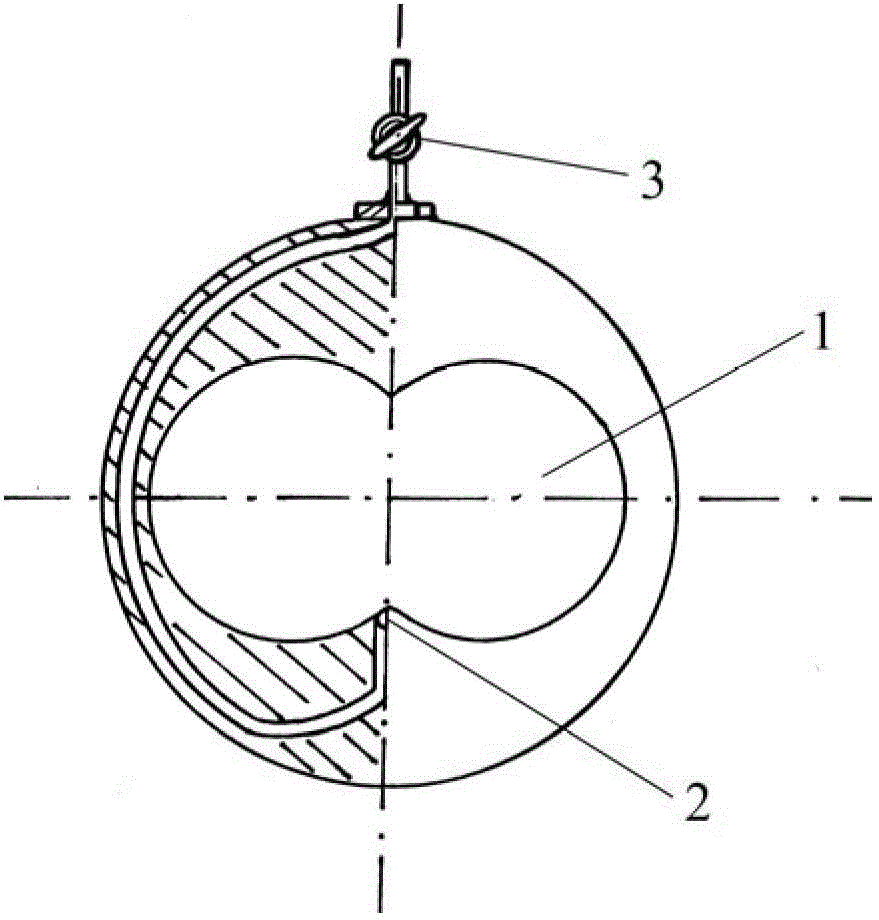

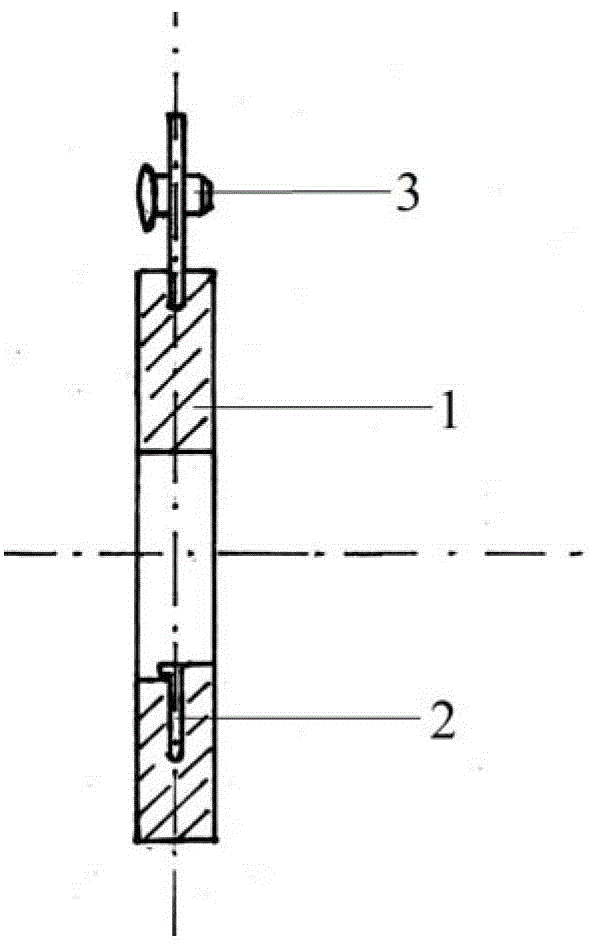

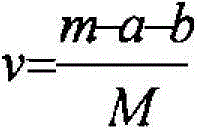

Image

Examples

Embodiment 1

[0056] The methyl methacrylate monomer is refined through active alumina and molecular sieves to meet the polymerization requirements of the present invention. Select polybutylacrylate pellets with 15% by mass of methyl methacrylate monomer as the modified resin, and set 3 feeding ports on the twin-screw extruder, respectively located at the first, second, and fourth screw extruders. The cylinder section is successively the feed port of pellets, the feed port of methyl methacrylate monomer, and the feed port of benzoyl peroxide initiator solution; under the feeding pump, the feed of methyl methacrylate pellets In the first section of the screw barrel, under the delivery of the metering pump, the refined monomer and initiator are respectively input into the second section and the fourth section for reaction extrusion polymerization reaction, and the structure of the number average molecular weight of 350,000 is methyl Product A of methyl acrylate homopolymer. The process condi...

Embodiment 2

[0061] A kind of reaction polymerization method of toughened polymethyl methacrylate, adopts the same processing condition of embodiment 1, polymethyl methacrylate-polybutyl methacrylate-polymethyl methacrylate nano-scale triblock The copolymer is dissolved in the methyl methacrylate monomer, and its mass ratio to the monomer is 1:8, and is fed into the extruder through the second screw barrel section, and the product B is finally obtained. The process conditions are set as follows:

[0062] The temperature of each section of the screw: 180 / 180 / 150 / 90 / 90 / 90 / 90 / 100 / 110 / 150 / 180 / 180 / 180°C; pellet feeding speed: 2.0kg / h; monomer mass flow rate: 8.0 kg / h; initiator mass flow rate: 24g / h; screw speed: 60rpm. The performance test results of product B are shown in Table 2.

[0063] Table 2

[0064]

Embodiment 3

[0066] Select high-molecular-weight polymethyl methacrylate as the modified resin, and set 4 feeding ports on the twin-screw extruder, which are respectively located in the first, second, sixth, and tenth screw barrel sections, followed by high-molecular-weight polymethyl methacrylate. Feed port for methyl acrylate and methyl methacrylate monomer, feed port for benzoyl peroxide initiator, feed port for dicumyl peroxide initiator, feed port for tert-butyl peroxybenzoate initiator Under the delivery of the metering pump, the refined monomer and initiator are input into the twin-screw extruder for reaction extrusion polymerization to obtain a methyl methacrylate homopolymer C with a number average molecular weight of 410,000.

[0067] The temperature of each section of the screw: 90 / 90 / 90 / 100 / 100 / 150 / 160 / 160 / 165 / 165 / 170 / 170 / 180°C; the mass flow rate of the monomer: 8.0kg / h; the mass flow rate of the initiator is 8g / h, 8.9g / h, 6.4g / h. Screw speed: 36 rpm. The performance test r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com