Preparation process of sludge electrical coal

A technology for electric coal and sludge, applied in sludge treatment, water/sludge/sewage treatment, petroleum industry, etc., can solve the problems of pathogen diffusion, heavy metal pollution, groundwater pollution, uneconomical energy consumption, etc. The effect of low moisture content requirement, lower processing cost and improved production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Embodiment 1: a kind of preparation process of sludge electric coal, comprises the following steps:

[0026] (1) Put the dewatered sludge into the hopper, add the dehydrating agent, use the twin-shaft pulverizer to pulverize, stir and mix, and spray the deodorant - G218 Bacillus natto to eliminate the odor during the process.

[0027] (2) Add combustion aids, biomass auxiliary fuel and raw coal to the sludge treated in step (1), transport it to a mixing crusher for pulverization and mix to obtain sludge thermal coal.

[0028] The dehydrating agent is red mud, sodium salt, bentonite and organic flocculant; the red mud is potassium aluminum sulfate dodecahydrate (ie alum), the sodium salt is sodium carbonate, and the bentonite is Activated clay, the organic flocculant is polyacrylamide.

[0029] The combustion aids are strong organic oxidants, magnesium salts, rare earths and sodium humate; the strong organic oxidants are potassium permanganate, the magnesium salts are m...

Embodiment 2- Embodiment 7

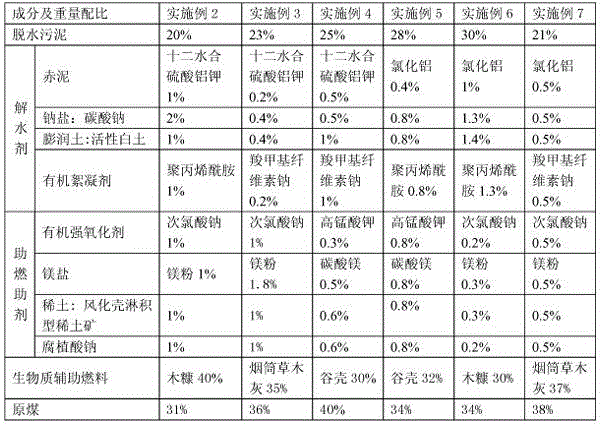

[0032] Embodiment 2-Embodiment 7: A preparation process of sludge electric coal, its specific steps are the same as in Embodiment 1, and the weight ratio of each component is shown in Attached Table 1.

[0033] Schedule 1

[0034]

[0035] The dewatered sludge described in this embodiment refers to sludge with a moisture content lower than or equal to 60% and a calorific value higher than 2000 kcal; the raw coal has a moisture content of 8-10% and a calorific value of 5000-5500 kcal; The chimney plant ash has a moisture content of 1-2%, a calorific value of 1000-1300 kcal, and wood chaff and chaff with a moisture content of 4-7%, and a calorific value of 6000-7000 kcal.

[0036] Each embodiment of the present invention can be prepared to reach the power plant coal standard with a calorific value of 4500-4700 kcal, a moisture content of less than 9%, an ash content of 40-60%, a volatile matter of 15-30%, and a sludge power plant with a sulfur content of less than 3%. coal. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com