Preparation method of nanoscale zirconium-doped lithium titanate material

A lithium zirconate titanate, nano-scale technology, which is applied in the field of electrochemical power supply material preparation, can solve the problems of low initial charge and discharge efficiency, easy reaction of electrolytes, and high cost of organic compounds, and achieves the benefits of migration and migration, shortening Heat treatment time, easy implementation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Disperse 34ml of tetra-n-butyl titanate in 60ml of deionized water to form A liquid; disperse 3.8g of lithium hydroxide monohydrate in 40ml of deionized water, and keep the ratio of the amount of lithium source and titanium source as no Li :n Ti =1:1.11, according to 1% of the total product mass, add 1.05ml of zirconium source solution with a zirconium ion concentration of 1mol / L to be liquid B;

[0025] 2) Under magnetic stirring, slowly add liquid B to liquid A, and stir for 30 minutes; pour the mixed solution into a high-temperature reactor, and then place it in an oven at 180°C for 12 hours. After the reaction, cool naturally to room temperature, and then carry out Suction filtration, washing with deionized water to pH=7, drying at 60°C to obtain the precursor;

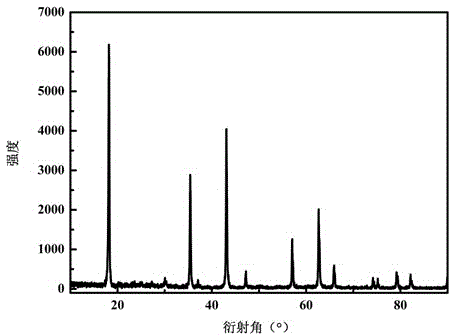

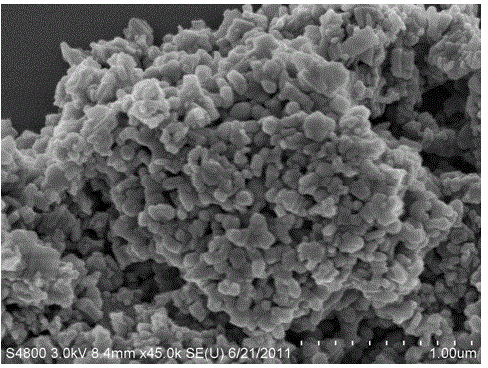

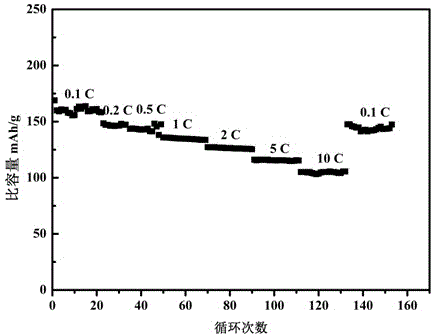

[0026] 3) The obtained precursor was sintered at 750° C. for 2 hours under a nitrogen atmosphere, and the obtained product was a nanoscale lithium zirconate-doped lithium titanate material.

[0027] T...

Embodiment 2

[0031] 1) Add 10g of amorphous TiO 2 Disperse in 50ml of deionized water, which is liquid A; disperse 11.6g of lithium acetate in 50ml of deionized water, and keep the ratio of the amount of lithium source and titanium source n Li :n Ti =1:1.1, according to 0.1% of the product mass, add 0.132ml of zirconium source solution with a zirconium ion concentration of 1mol / L to be liquid B;

[0032] 2) Under magnetic stirring, slowly add liquid B to liquid A, and stir for 30 minutes; pour the mixed solution into a high-temperature reaction kettle, and then place it in a 120°C oven for 24 hours. After the reaction, cool naturally to room temperature, and then carry out Suction filtration, washing with deionized water, and drying at 120°C to obtain the precursor;

[0033] 3) The obtained precursor was sintered at 600° C. for 5 hours under a nitrogen atmosphere, and the obtained product was a nano-scale lithium zirconate-doped lithium titanate material.

[0034] The test method is con...

Embodiment 3

[0036] 1) Disperse 402g of titanium sulfate in 500ml of deionized water to form A liquid; disperse 85g of lithium acetate in 500ml of deionized water, and keep the amount ratio of lithium source and titanium source n Li :n Ti =1:1.2, add 5.27ml of zirconium source solution with a zirconium ion concentration of 1mol / L according to 0.5% of the product mass, to be liquid B;

[0037] 2) Under magnetic stirring, slowly add liquid B to liquid A, and stir for 30 minutes; pour the mixed solution into a high-temperature reactor, and then place it in a 200°C oven for 12 hours. After the reaction, cool naturally to room temperature, and then carry out Suction filtration, washing with deionized water, and drying at 100°C to obtain the precursor;

[0038] 3) The obtained precursor was sintered at 1000° C. for 1 h in a nitrogen atmosphere, and the obtained product was nano-scale zirconium-doped lithium titanate material.

[0039] The test method is consistent with that of Example 1, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com