Silica crucible and method for fabricating the same

A quartz crucible and quartz glass technology, applied in crucible furnaces, manufacturing tools, glass manufacturing equipment, etc., can solve the problems of coating scratches, scratches, peeling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

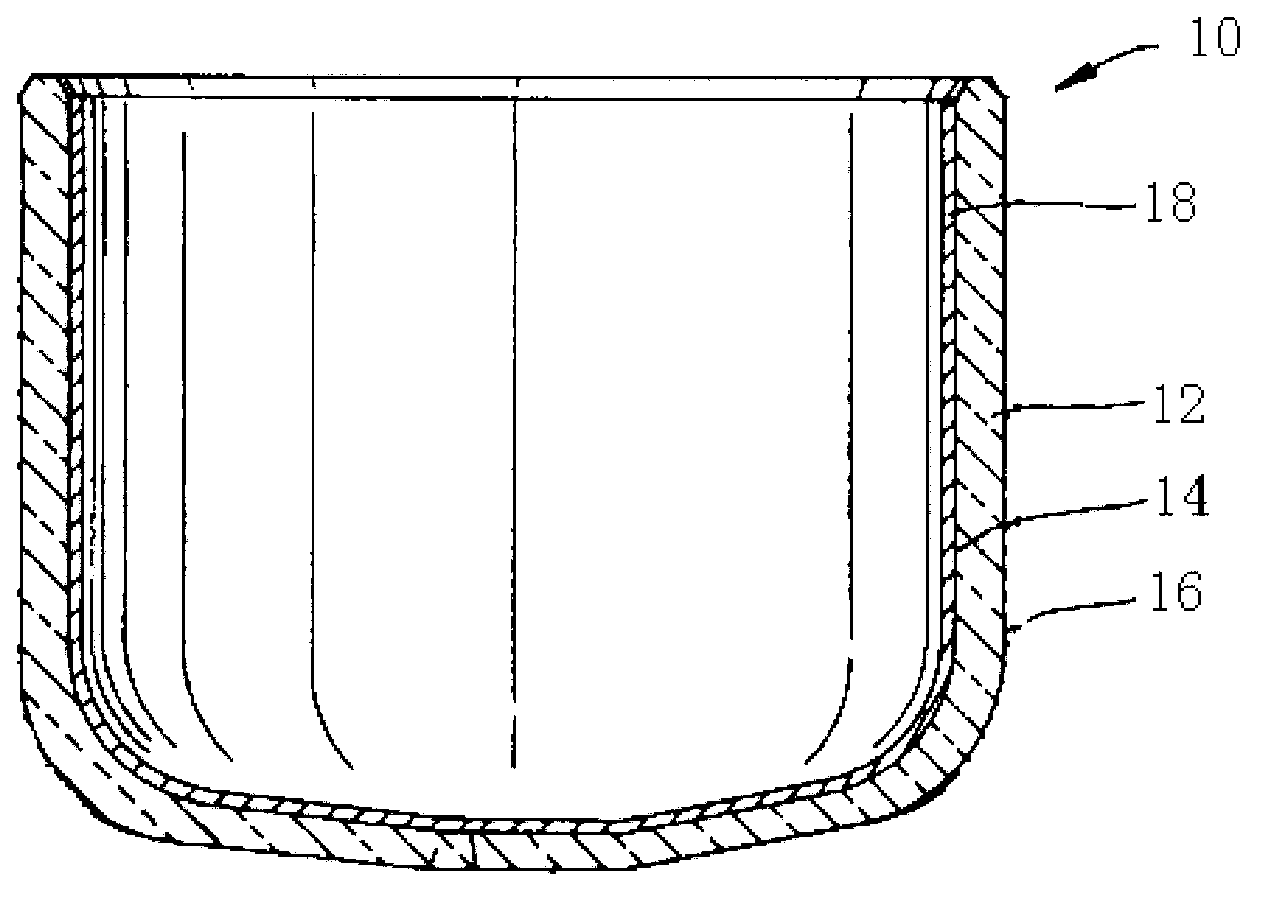

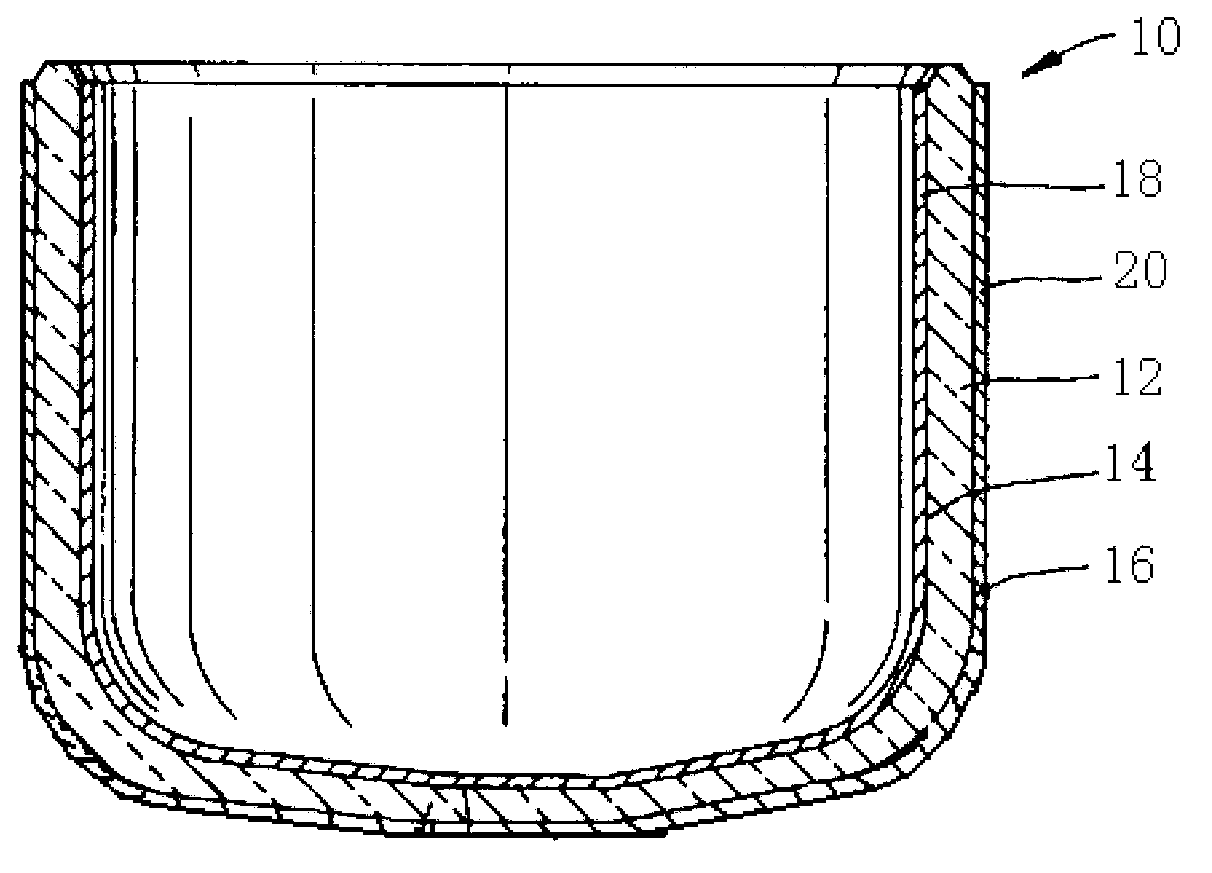

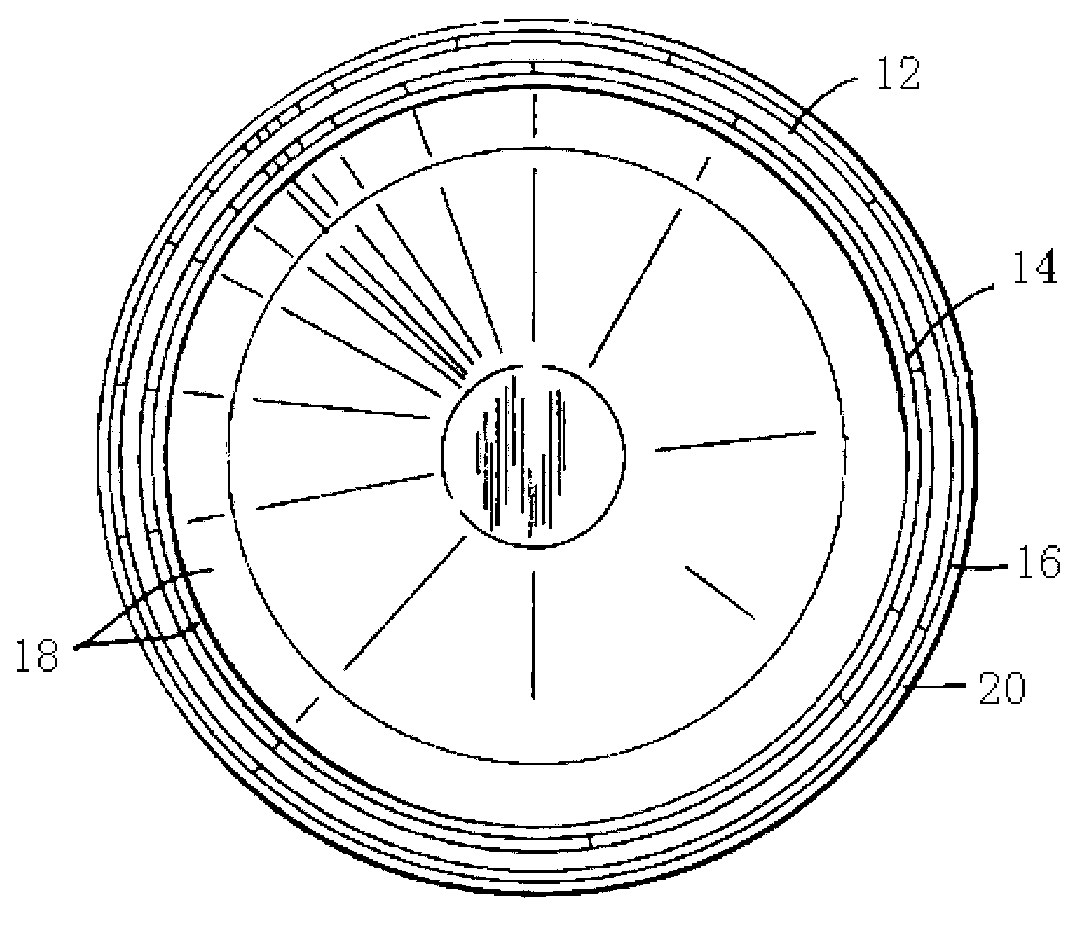

[0098] In order to solve the above problems, the present invention provides a quartz crucible and a manufacturing method thereof. The quartz crucible includes: a quartz glass body having an inner surface and an outer surface, the inner surface constituting a cavity for containing molten material or powder material; and a first coating formed on the inner surface of the quartz glass body. layer. The quartz glass body is formed of quartz crystal, quartz sand or quartz glass sand with a grain size ranging from 1 micron to 600 microns. The quartz glass body can be formed by flame melting, electric melting or arc plasma melting. Depending on the quality of the quartz crystal, quartz sand or quartz glass sand, the quartz glass body can be produced with a structure of different layers. The first coating is formed by pyrolyzing compounds of aluminum, magnesium, calcium, titanium, zirconium, radium, chromium, selenium, barium, yttrium, cerium, hafnium, tantalum, tin or silicon at a p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com