Green solvent modified zeolite phenol sorbent and preparation method thereof

A modified zeolite and green solvent technology, which is applied in chemical instruments and methods, crystalline aluminosilicate zeolite, and other chemical processes, can solve the problems of complex regeneration, low processing efficiency, and high cost, and achieve improved adsorption capacity, The effect of easy to obtain raw materials and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

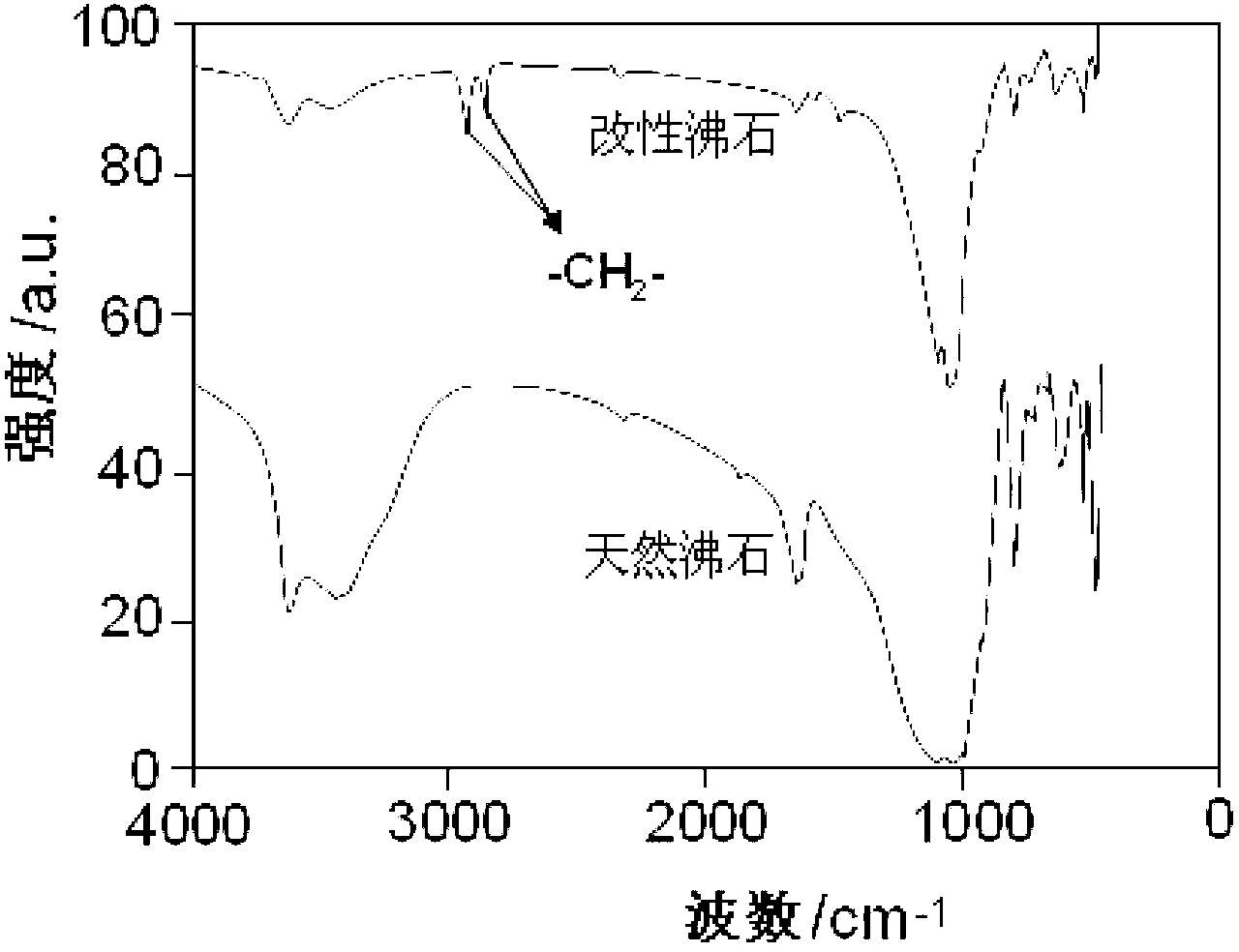

[0020] Example 1: Preparation of Green Solvent Modified Zeolite Phenol Adsorbent

[0021] (1) Raw materials and reagents

[0022] Natural zeolite, fineness 200 mesh, Shangtianlai, Xinyang, Henan.

[0023] Hexadecyl-3-methylimidazolium chloride, molecular weight 361.01, CAS: 404001-62-3, Shanghai Darui Fine Chemicals Co., Ltd.

[0024] (2) Preparation steps

[0025] A. get the hexadecyl-3-methylimidazolium chloride aqueous solution whose concentration is 1.1wt%, adjust the pH of the solution to 7.5 with NaOH solution, and prepare the modifying agent solution;

[0026] B. Mix 50ml modifier solution with 5g natural zeolite, place it in a constant temperature shaker in a water bath, and vibrate at 20°C for 30min;

[0027] C. Carry out solid-liquid separation in a centrifuge, take the precipitate and wash it with distilled water and then centrifuge, repeat the above steps until the supernatant is tested with silver nitrate solution and there is no white precipitate;

[0028] D....

Embodiment 2

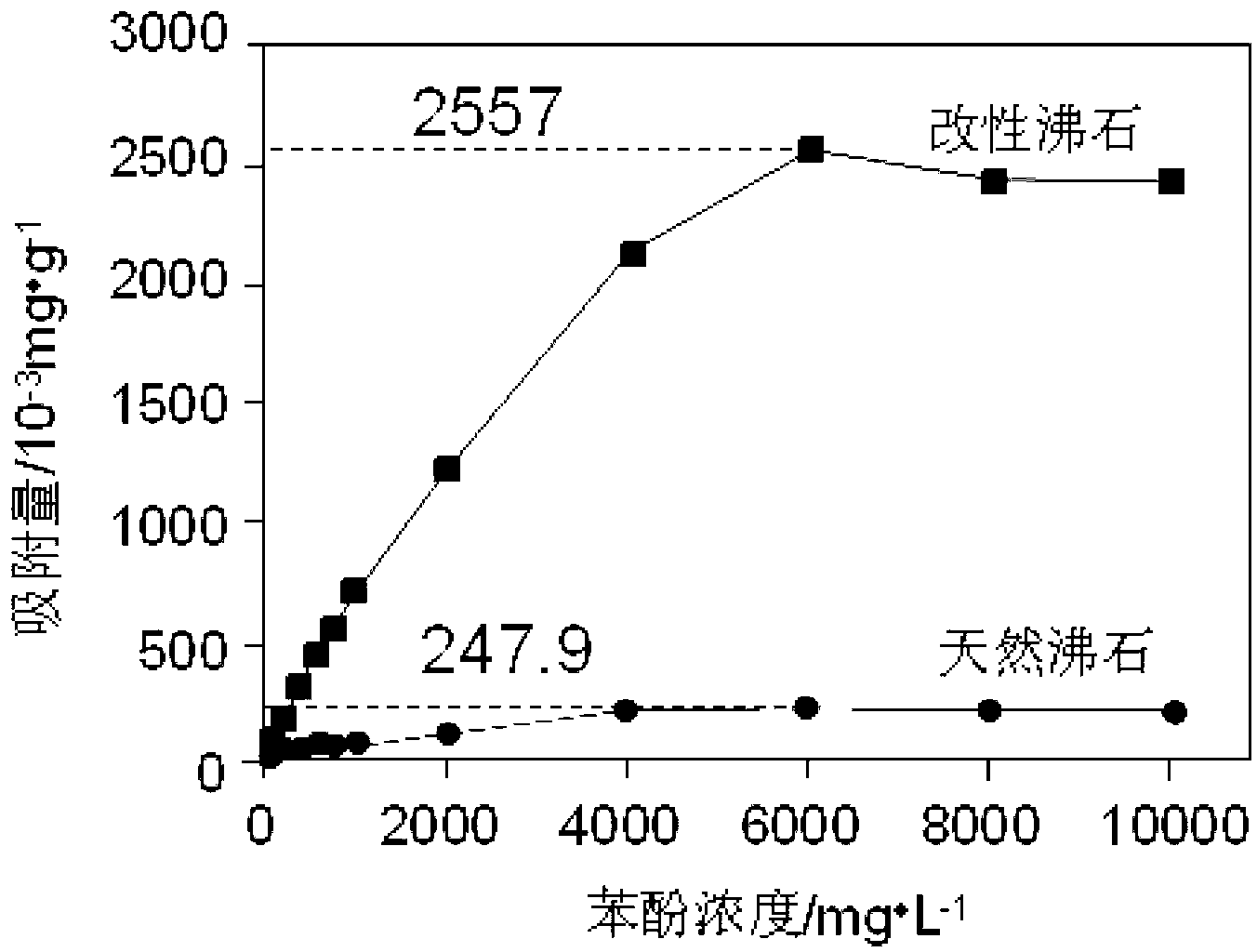

[0030] Embodiment 2 Phenol adsorption performance measurement

[0031] (1) Samples and reagents

[0032] 1) Natural zeolite, fineness 200 mesh, Xinyang Shangtianti, Henan.

[0033] 2) Modified zeolite, prepared in Example 1.

[0034] 3) Phenol-free water: Add 0.2g of activated carbon powder activated at 200°C for 0.45h to 1L of water, shake well, and let stand overnight. Filter with double-layer medium-speed filter paper, transfer to a distillation flask for heating and distillation, and collect the distillate for later use.

[0035] 4) Phenol standard stock solution: Weigh 1g of phenol and dissolve it in water, transfer it into a 1L volumetric flask, dilute with water to the marked line, and shake well. ρ = 1 g / L. Stored in the refrigerator, it is stable for at least one month.

[0036] 5) Phenol standard intermediate solution: Take 1mL of phenol stock solution in a 100mL volumetric flask and dilute with water to the marked line. ρ = 10.0mg / L. Configured on the day of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com