Glass ceramic with high dielectric constant and low dielectric loss and preparation method thereof

A high dielectric constant, glass ceramic technology, applied in the field of glass ceramics and its preparation, can solve the problems of limiting the effective dielectric constant of composite materials, large loss, reducing the reliability and life of capacitors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

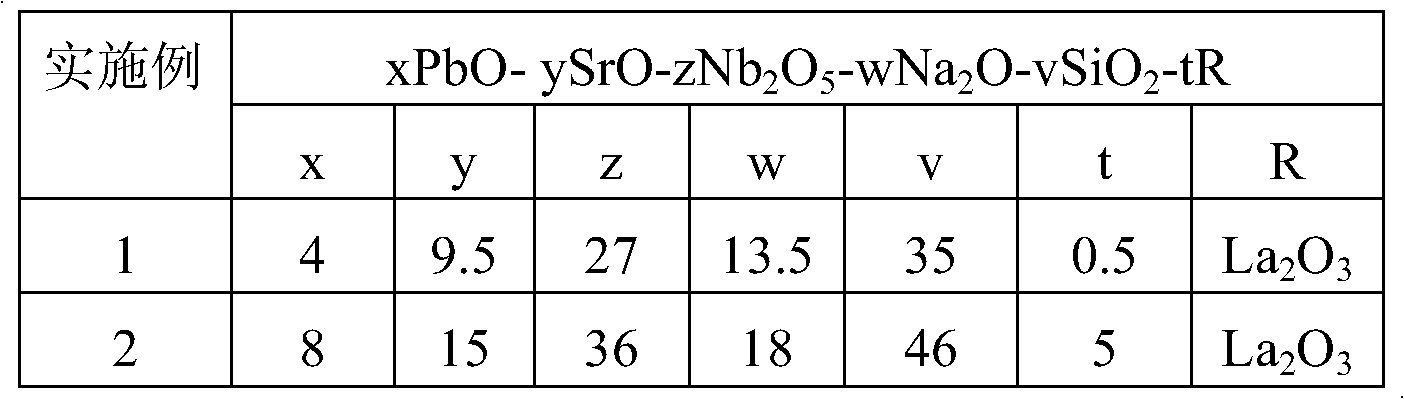

[0020] Choose analytically pure PbO, SrCO 3 , Nb 2 o 5 、Na 2 CO 3 , SiO 2 and La 2 o 3 As raw materials, according to the molar ratio in Table 1, the ingredients are respectively prepared, using deionized water as the dispersion medium, zirconia balls as the grinding medium, mixing in a nylon tank for 4 hours by using an overturning mixer, and mixing the homogeneous slurry at 120 °C oven dry.

[0021] Then the homogeneously mixed raw materials were added into a platinum crucible, and kept at a high temperature of 1450° C. for 3 hours. Then pour the evenly melted molten glass into a metal mold preheated to 550°C in advance, and put it into an annealing furnace for stress relief annealing after forming. After 6 hours of heat preservation, turn off the annealing furnace and cool with the furnace to prepare 1 ~2 mm thick glass sheet.

[0022] The prepared glass sheet is subjected to controllable crystallization heat treatment, and the treatment process is as follows: firs...

Embodiment 2~6

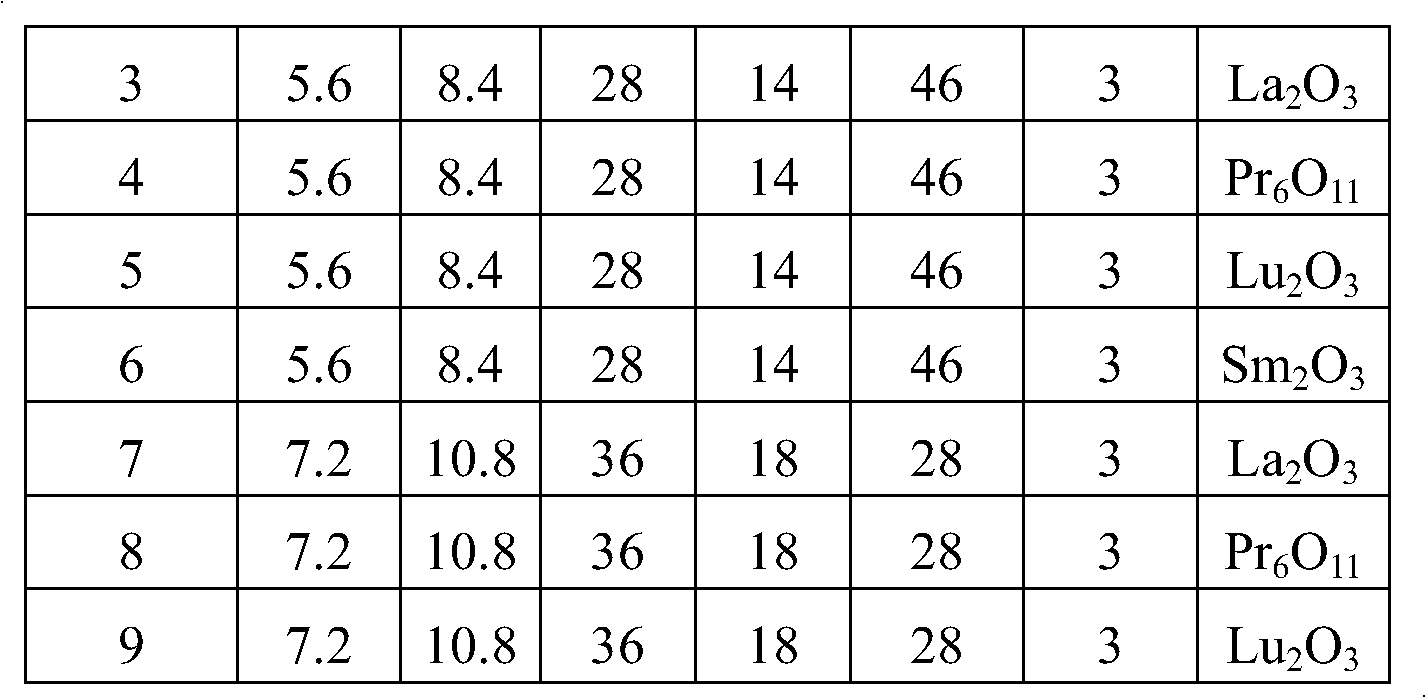

[0024] Select analytically pure PbO, Sr(NO 3 ) 2 , Nb 2 o 5 , NaOH, SiO 2 and R as raw materials, according to the molar ratio in Table 1, respectively, according to the proportion of ingredients, using deionized water as the dispersion medium, zirconia balls as the grinding medium, in a nylon tank using a flipping mixer for 4 hours to mix the uniform slurry Dry in an oven at 120°C.

[0025] Then the homogeneously mixed raw materials were added into a platinum crucible, and kept at a high temperature of 1450° C. for 3 hours. Then pour the evenly melted molten glass between the two rollers of the rotating calender, press it into a glass sheet with a thickness of 1-2mm, and then immediately enter the annealing furnace for stress relief annealing. After 6 hours of heat preservation, turn off the annealing furnace. Cool in the furnace to produce glass flakes.

[0026] The prepared glass sheet is subjected to controllable crystallization heat treatment, and the treatment proc...

Embodiment 7~9

[0028] Select analytically pure PbO, Sr(NO 3 ) 2 , Nb 2 o 5 、NaNO 3 , SiO 2 and R as raw materials, according to the molar ratio in Table 1, respectively, according to the proportion of ingredients, using deionized water as the dispersion medium, zirconia balls as the grinding medium, in a nylon tank using a flipping mixer for 4 hours to mix the uniform slurry Dry in an oven at 120°C.

[0029] Then the homogeneously mixed raw materials were added into a platinum crucible, and kept at a high temperature of 1450° C. for 3 hours. Then pour the evenly melted molten glass into a metal mold preheated to 550°C in advance, and put it into an annealing furnace for stress relief annealing after forming. After 6 hours of heat preservation, turn off the annealing furnace and cool with the furnace to prepare 1 ~2 mm thick glass sheet.

[0030] The prepared glass sheet is subjected to controllable crystallization heat treatment, and the treatment process is as follows: firstly, the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com