Water-dispersible sizing agent, method of manufacturing paper, and method of manufacturing paperboard

A manufacturing method and dispersive technology, applied in the field of paperboard manufacturing, can solve the problems of insufficient reduction of papermaking pollution, difficulty in use, poor stability of dispersant at low temperature, etc., and achieve excellent sizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~4

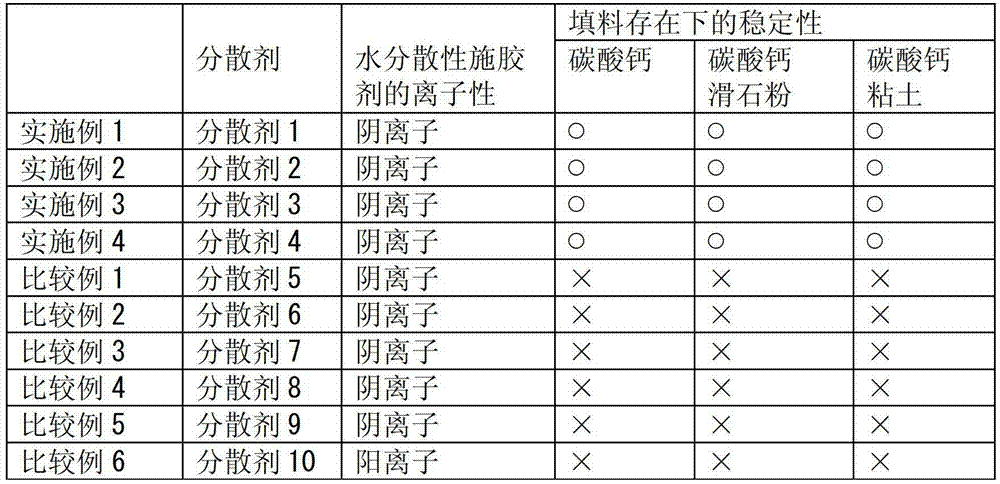

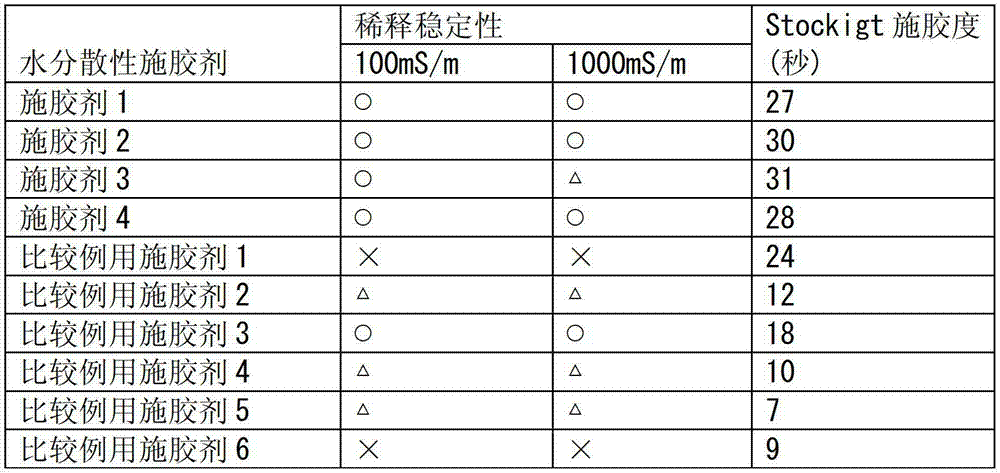

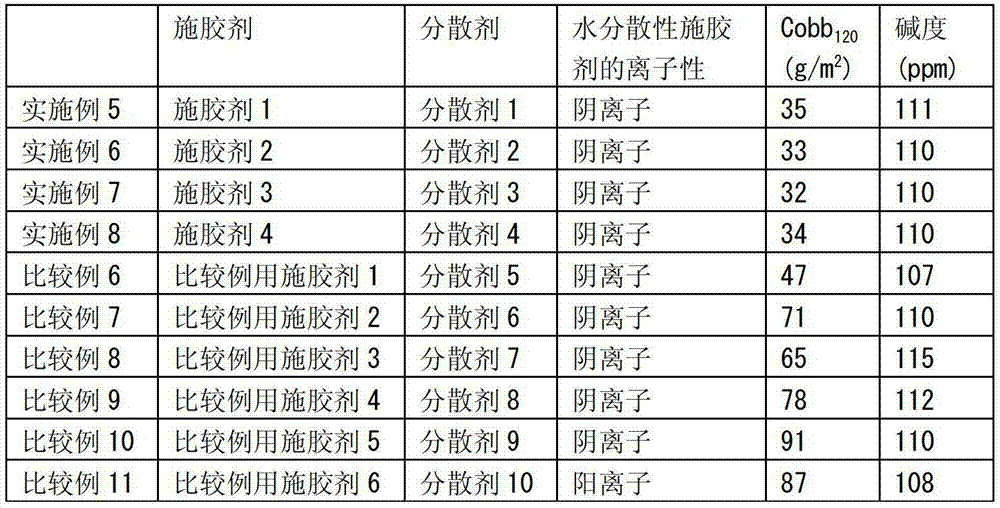

[0078] (Examples 1-4), Comparative Examples 1-6)

Synthetic example 1

[0080] Prepare a mixture of 275 parts by mass of an aqueous acrylamide solution having a concentration of 40% by mass, 25 parts by mass of an aqueous 40% by mass acrylic acid solution, and 595 parts by mass of water under a nitrogen atmosphere, and then add 2% by mass of ammonium persulfate to the mixture at a temperature of 50°C. 5 mass parts of aqueous solution and 5 mass parts of 2 mass % sodium bisulfite aqueous solution, spend 3 hours under 80 ℃ to make above-mentioned acrylamide and acrylic acid copolymerization reaction, add 40 mass % naphthalenesulfonic acid formaldehyde condensate sodium salt aqueous solution ( Demol-NL, Kao Corporation) 75 parts by mass, and the thus obtained mixture was diluted with water to obtain a dispersant 1 having a solid content concentration of 10 mass%.

Synthetic example 2

[0082] Except that the mixture of 275 parts by mass of acrylamide aqueous solution with a concentration of 40 mass %, 25 parts by mass of acrylic acid aqueous solution of 40 mass % and 595 parts by mass of water is replaced by an aqueous solution of acrylamide with a concentration of 40 mass % under nitrogen atmosphere 264 Parts by mass, 25 parts by mass of an aqueous 40 mass % acrylic acid solution, 11 parts by mass of an aqueous 40 mass % dimethylaminopropylacrylamide solution and 595 parts by mass of water, all the same as in Synthesis Example 1 above, to obtain a solid content concentration of 10 mass parts % of dispersant 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com