Low-temperature denitration catalyst for smoke and preparation method thereof

A low-temperature denitrification and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, separation methods, etc., can solve the problems of narrow operating temperature window, high catalyst cost, easy sintering of catalyst, etc., and achieve good low-temperature activity, high The effect of specific surface area and strong anti-sintering ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

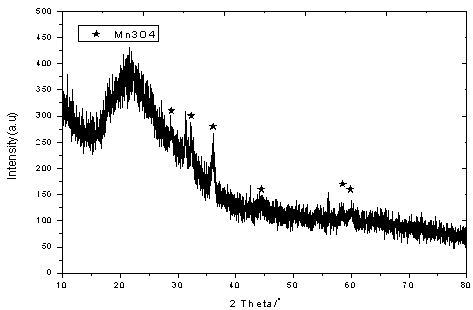

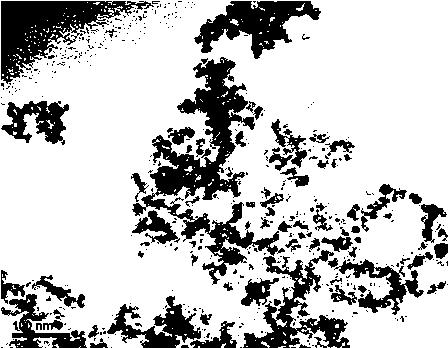

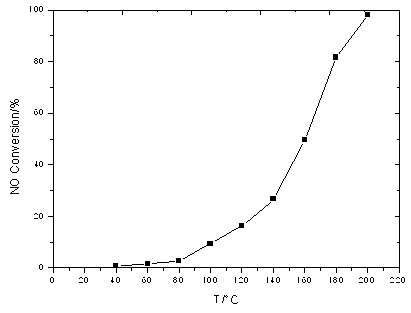

[0021] Take 1g SiO 2 (The specific surface is about 200 m 2 / g) was dispersed in 200 mL of absolute ethanol, and 2 mL of deionized water was added. 50 mL of 4.6667 g / L citric acid ethanol solution was added dropwise to the system, and the adsorption was stirred at 30 °C for 3 h. Then 50 mL of manganese acetate ethanol solution with a concentration of 8.1667 g / L was added dropwise to the system, and reacted at 30 °C for 3 h. After fully reacting, the catalyst precursor was obtained, and after suction filtration and drying, the sample was roasted in a muffle furnace at 400 °C for 5 h to obtain the catalyst. XRD analysis showed that the supported MnOx in the catalyst was Mn 3 o 4 exists in the form of (such as figure 1 shown), the TEM test results show that the catalyst prepared by this method has good dispersion (such as figure 2 shown), the catalyst is applied to flue gas denitrification, and the conversion rate of NO can reach 80% at 180 °C, and can reach more than 90% ...

Embodiment 2

[0023] Take 0.2g SiO 2 Disperse in 200 mL of anhydrous methanol and add 0.2 mL of deionized water. 50 ml of 5.3333 g / L methanolic NaOH solution was added dropwise to the system, and stirred and adsorbed at 30 °C for 3 h. 50 mL of manganese nitrate methanol solution with a concentration of 23.8095 g / L was added dropwise to the system, and reacted at 30 °C for 3 h. After fully reacting, the catalyst precursor was obtained, and after suction filtration and drying, the sample was roasted in a muffle furnace at 300 °C for 5 h to obtain the catalyst. When this catalyst is applied to flue gas denitrification, the conversion rate of NO can reach 70% at 160 °C and more than 80% at 200 °C.

Embodiment 3

[0025] Take 1g SiO 2 Disperse in 200 mL of anhydrous propanol, add 1 mL of deionized water. 50 mL of 12 g / L oxalic acid in propanol was added dropwise to the system, and the adsorption was stirred at -5 °C for 24 h. 50 mL of 26.4 g / L manganese chloride propanol solution was added dropwise to the system, and reacted at -5 °C for 3 h. After fully reacting, the catalyst precursor was obtained. After suction filtration and drying, the sample was roasted in a muffle furnace at 700 °C for 5 h to obtain the catalyst. When this catalyst is applied to flue gas denitrification, the conversion rate of NO can reach 55% at 160 °C and more than 60% at 200 °C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com