Catalyst for preparing chloroethylene through acetylene hydrochlorination

A technology for the production of vinyl chloride and catalysts by chlorination, which is applied in the direction of physical/chemical process catalysts, organic compound/hydride/coordination complex catalysts, hydrogen halide addition preparation, etc., which can solve poor safety, short life, and low activity And other problems, to achieve the effect of not easy to lose and prolong life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Carbon carrier: activated carbon, bulk density 0.50g / ml, BET specific surface area 387m 2 / g, particle size 3.5~4.0mm, particle length 3~10mm. Measure 40ml of this activated carbon.

[0036] Active component: weigh CuCl 2 2.70 g of 2H2O (chemically pure, molecular weight 170.48, content 99%) was dissolved in about 30 ml of distilled water. Weigh 3.50 g of 1,10-phenanthroline (molecular weight 198.22 analytically pure, water content 10%) and dissolve it in about 30 ml of absolute ethanol to obtain solution B.

[0037] Catalyst: Pour the dried activated carbon into solution A and dry it again in a drying oven; then pour the dried activated carbon into solution B and dry it again in a drying oven.

[0038] Phenomenon: good activity, no loss of ligand.

Embodiment 2

[0040] Carbon carrier: activated carbon, bulk density 0.50g / ml, BET specific surface area 387m 2 / g, particle size 3.5~4.0mm, particle length 3~10mm. Measure 40 ml of the activated carbon, raise the temperature to 750° C., and treat it with ammonia gas and water vapor for 40 minutes.

[0041] Active ingredient: Weigh 0.016mol of nickel porphyrin and dissolve it in about 50ml of hot ethanol to obtain solution A.

[0042] Catalyst: Activated carbon is poured into solution A and dried in a drying oven; then the dried activated carbon is poured into solution B and dried in a drying oven again.

[0043] Phenomenon: good activity, no loss of ligand.

Embodiment 3

[0045] Carbon carrier: activated carbon, bulk density 0.38g / ml, BET specific surface area 1091m 2 / g, particle size 2.5mm, particle length 2-5mm.

[0046] Catalyst: prepare 50ml of 0.016mol copper chloride aqueous solution, impregnate the above-mentioned activated carbon, dry, then add 12g of phthalic anhydride, 12g of urea, seal the autoclave, heat at 280°C for 24h, take it out and wash it with distilled water for 5 times, then wash with ethanol 5 times, dry. Then, evaluation was performed using the aforementioned evaluation device.

[0047] Phenomenon: relatively high activity, no loss of ligand or organic base.

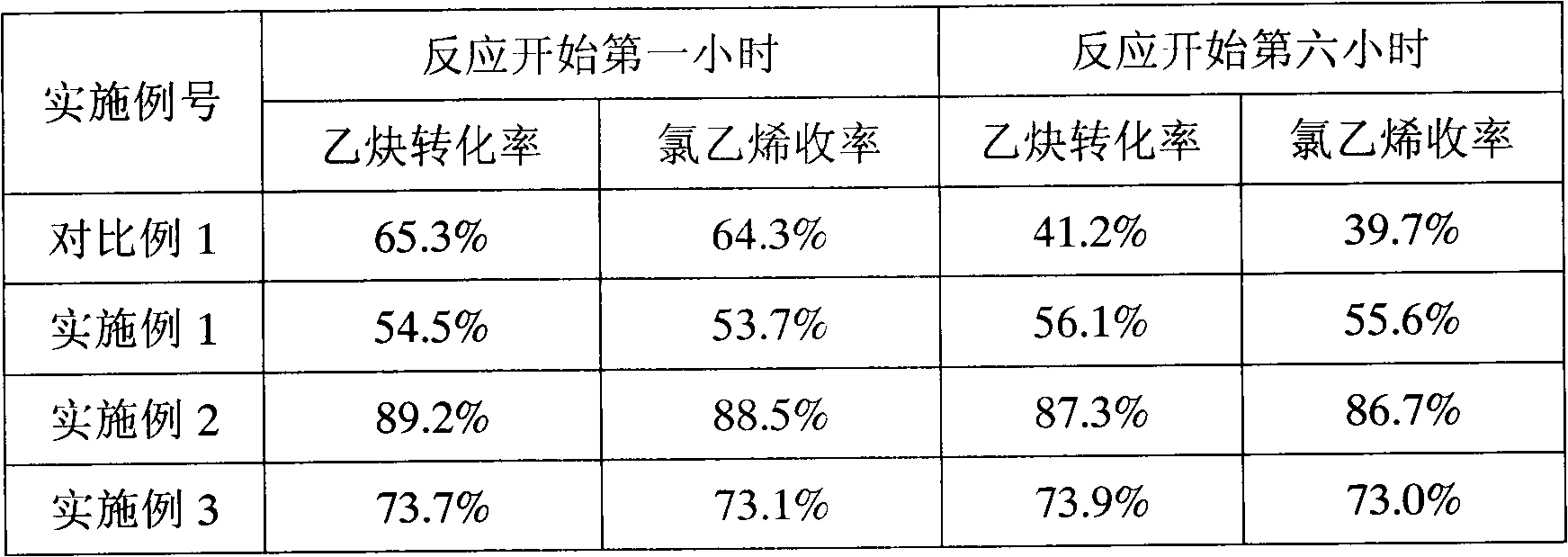

[0048] Table 1. Catalyst evaluation results

[0049]

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com