Brazing filler alloy powder and preparation method thereof

A technology of alloy powder and solder, which is applied in the field of preparation of ultrafine Mo-Ru-B solder alloy powder by jet mill crushing, which can solve the problem of increased temperature difference between solid and liquidus of solder and poor brazing processability , Uneven solder composition and other problems, to achieve the effect of improving the performance of the process, improving the brazing characteristics, and improving the welding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

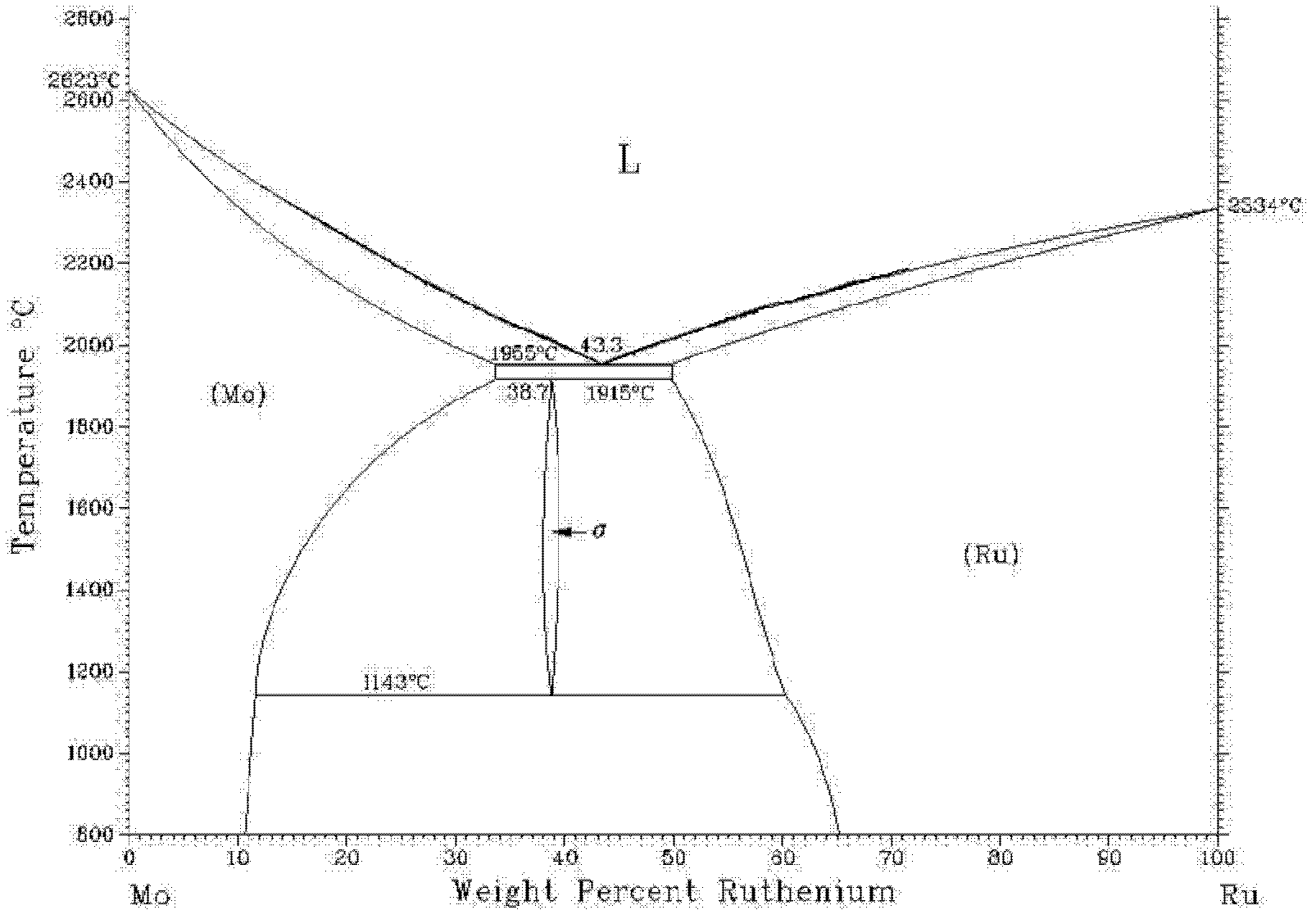

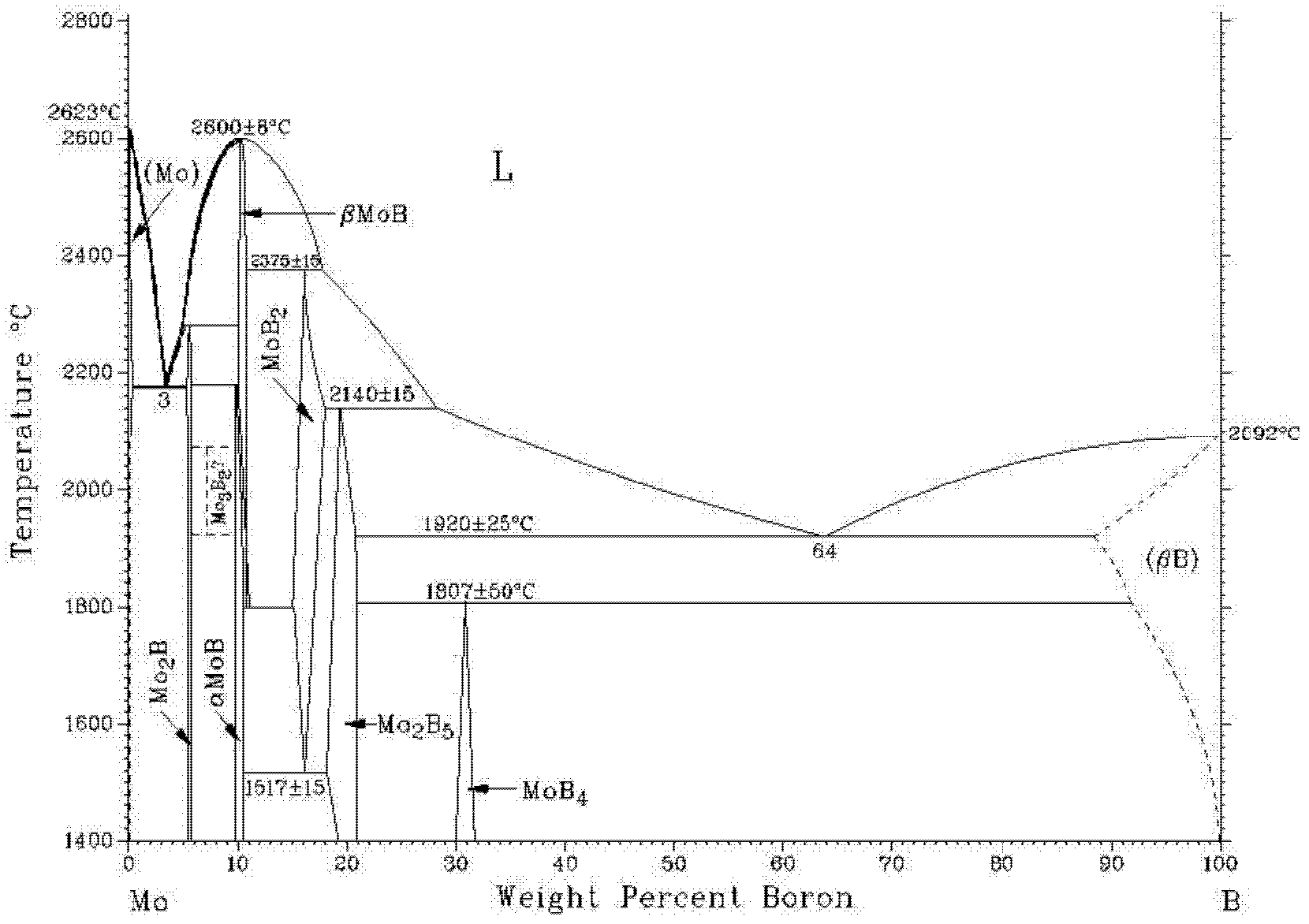

[0026] A solder alloy powder, the composition (mass fraction) is as follows: 55%Mo-43%Ru-2%B.

[0027] The main steps of the above-mentioned solder alloy powder preparation method are as follows:

[0028] First, the high-purity and ultrafine Mo powder, Ru powder, and B powder are subjected to hydrogen burning and impurity removal treatment, weighed according to the above-mentioned solder composition ratio, powder mixed, and granulated. The solder preform is made by cold isostatic pressing, and after dewaxing under the protection of hydrogen atmosphere, it is sintered at 1200°C (hydrogen atmosphere); the sintered solder preform needs to be electron beam vacuum smelted to remove impurities (gas and high temperature) Vapor pressure impurities, etc.), vacuum requirements: the vacuum of the furnace body is better than 5×10 -3 Pa, electron gun vacuum is better than 5×10 -4 Pa; the solder alloy ingot (Φ30mm alloy rod) obtained by electron beam smelting is pulverized (coarse powder)...

Embodiment 2

[0031] A solder alloy powder, the composition (mass fraction) is as follows: 55.5%Mo-42%Ru-2.5%B.

[0032] The main steps of the above-mentioned solder alloy powder preparation method are as follows:

[0033] First, the high-purity and ultrafine Mo powder, Ru powder, and B powder are subjected to hydrogen burning and impurity removal treatment, weighed according to the above-mentioned solder composition ratio, powder mixed, and granulated. The solder preform is made by cold isostatic pressing, and after dewaxing under the protection of hydrogen atmosphere, it is sintered at 1350°C (hydrogen atmosphere); the sintered solder preform needs to be electron beam vacuum smelted to remove impurities (gas and high temperature) Vapor pressure impurities, etc.), vacuum requirements: the vacuum of the furnace body is better than 5×10 -3 Pa, electron gun vacuum is better than 5×10 -4 Pa; The solder alloy ingot (Φ30mm alloy rod) obtained by electron beam smelting is pulverized (coarse pow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com