A kind of nanometer magnesium oxide triclosan composite nanometer antibacterial agent

A technology of nano-magnesium oxide and nano-antibacterial agent, which is applied in the field of antibacterial agents, can solve the problems such as the undeveloped nano-magnesia functional powder preparation process, and achieve the effects of easy industrial production, simple preparation process, and rapid sterilization ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

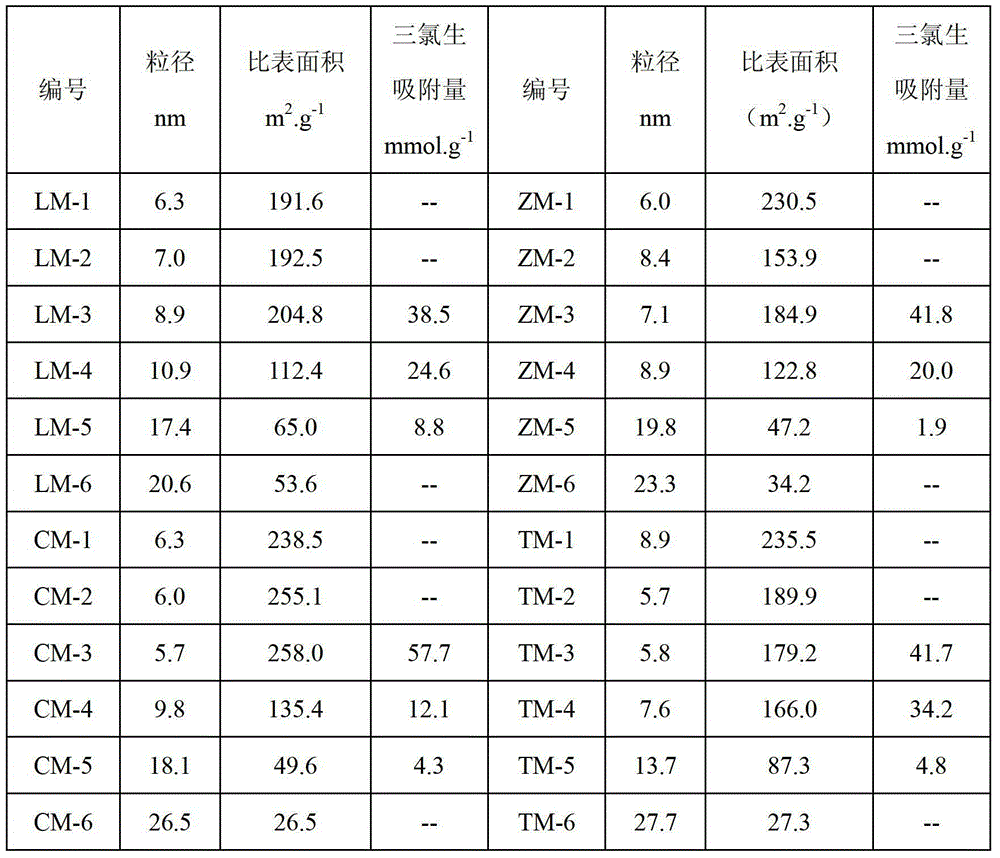

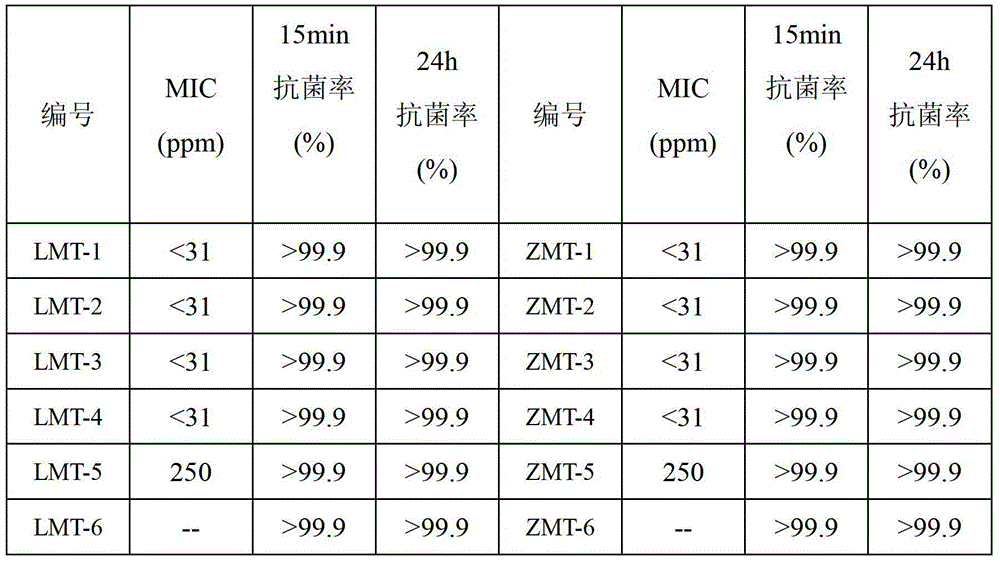

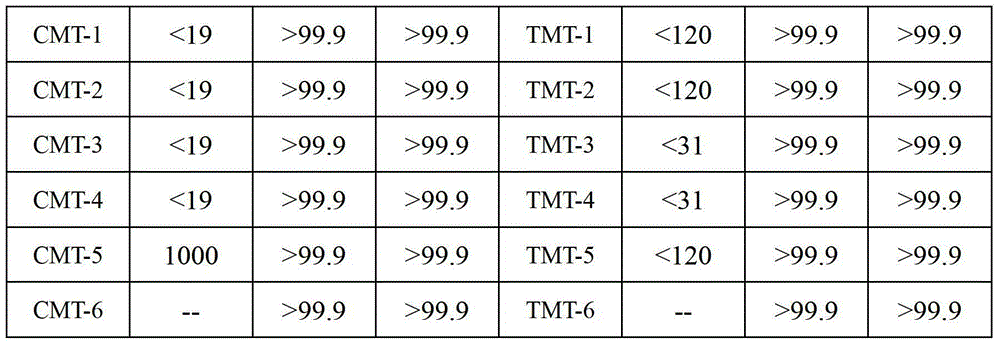

Embodiment 1

[0048] according to + / Mg 2+ (mol / mol)=0.01 ratio, directly mix 20ml of ethanol solution of lithium salt with 500ml of 0.5mol magnesium nitrate ethanol solution, and stir evenly at room temperature; after that, directly add 500ml of ethanol solution containing equimolar oxalic acid In the magnesium ethanol solution, after continuous stirring for 30 minutes, the precursor gel was obtained after standing at room temperature for 8 hours; the gel was filtered, washed with ethanol for 3 to 5 times, and dried at 80° C. for 48 hours to obtain the xerogel of the magnesium oxide precursor. Finally, the obtained xerogel was sintered at a high temperature of 500°C for 1 hour to obtain lithium ion-doped nano-magnesia powder LM-1; 0.5 g of lithium-doped nano-magnesia powder was weighed and added to 120 ppm triclosan ethanol solution , stirred at room temperature for 12h. After that, centrifuge, wash with ethanol for 2-3 times, and dry at 80°C to obtain the composite antibacterial agent L...

Embodiment 2

[0050] According to Li + / Mg 2+ (mol / mol)=0.05 ratio, directly mix 20ml of ethanol solution of lithium salt with 500ml of 0.3mol magnesium nitrate ethanol solution, and stir evenly at room temperature; after that, directly add 500ml of ethanol solution containing equimolar oxalic acid In the magnesium ethanol solution, after continuous stirring for 30 minutes, the precursor gel was obtained after standing at room temperature for 24 hours; the gel was filtered and washed with ethanol for 3 to 5 times, and dried at 120° C. for 12 hours to obtain the xerogel of the magnesium oxide precursor. Finally, the obtained dry gel was sintered at a high temperature of 500° C. for 5 hours to obtain lithium ion-doped nano magnesium oxide powder LM-2. The prepared 0.1 g of lithium-doped nano magnesium oxide was weighed, added to 80 ppm triclosan ethanol solution, and stirred at room temperature for 5 h. After that, centrifuge, wash with ethanol for 2-3 times, and dry at 80°C to obtain the c...

Embodiment 3

[0052] According to Li + / Mg 2+ (mol / mol)=0.02 ratio, directly mix 20ml of ethanol solution of lithium salt with 500ml of 0.2mol magnesium nitrate ethanol solution, and stir evenly at room temperature; after that, directly add 500ml of ethanol solution containing equimolar oxalic acid In the magnesium ethanol solution, after continuous stirring for 30 minutes, the precursor gel was obtained after standing at room temperature for 12 hours; the gel was filtered, washed with ethanol for 3 to 5 times, and dried at 100° C. for 24 hours to obtain the xerogel of the magnesium oxide precursor. Finally, the obtained dry gel was sintered at a high temperature of 500° C. for 2 hours to obtain lithium ion-doped nano magnesium oxide powder LM-3. Weigh the prepared 0.3g of lithium-doped nano magnesium oxide, add it into the 100ppm triclosan ethanol solution, and stir at room temperature for 8h. After that, centrifuge, wash with ethanol for 2-3 times, and dry at 80°C to obtain the composit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com