Star silsesquioxane-grafted acrylic ester-sulfonated styrene segmented copolymer and preparation method thereof

A technology of silsesquioxane and sulfonated styrene, used in electrochemical generators, fuel cells, electrical components, etc. The effect of hydrophilicity and superior thermal stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

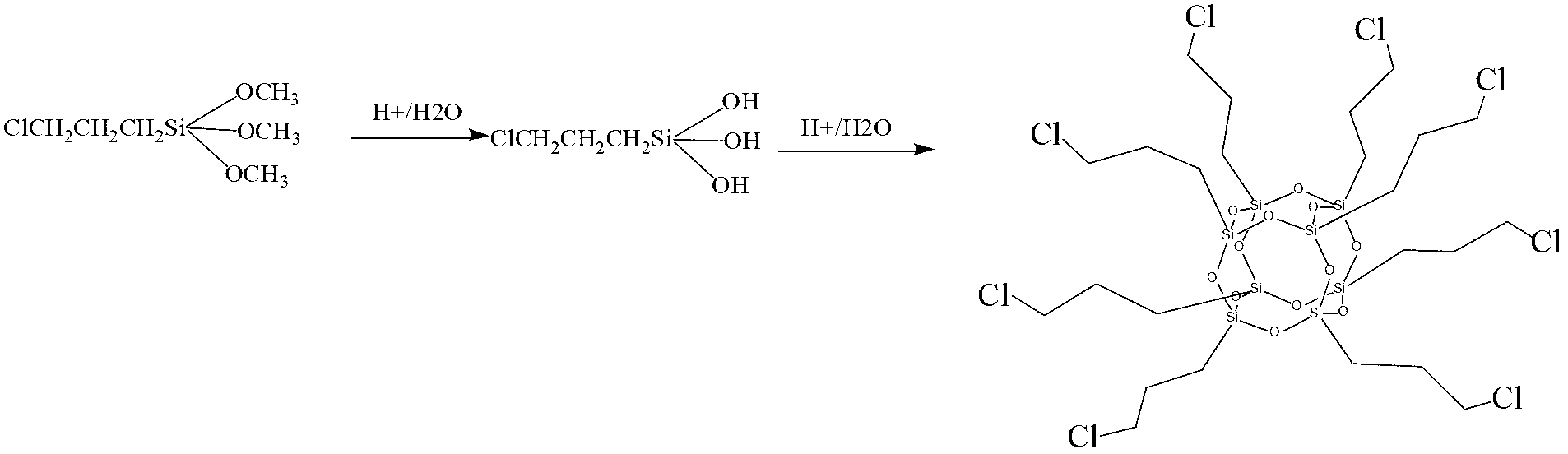

[0027] (1) Step 1: Add 600ml of anhydrous methanol, 24ml of concentrated hydrochloric acid, and 30ml of γ-chloropropyltrimethoxysilane to a 1000ml three-necked flask in sequence, and continuously stir the reaction at 40°C for 5 days to obtain a white solid. Rinse several times, and dry in a vacuum oven at 50°C for 48 hours. Synthetic process such as figure 1 shown;

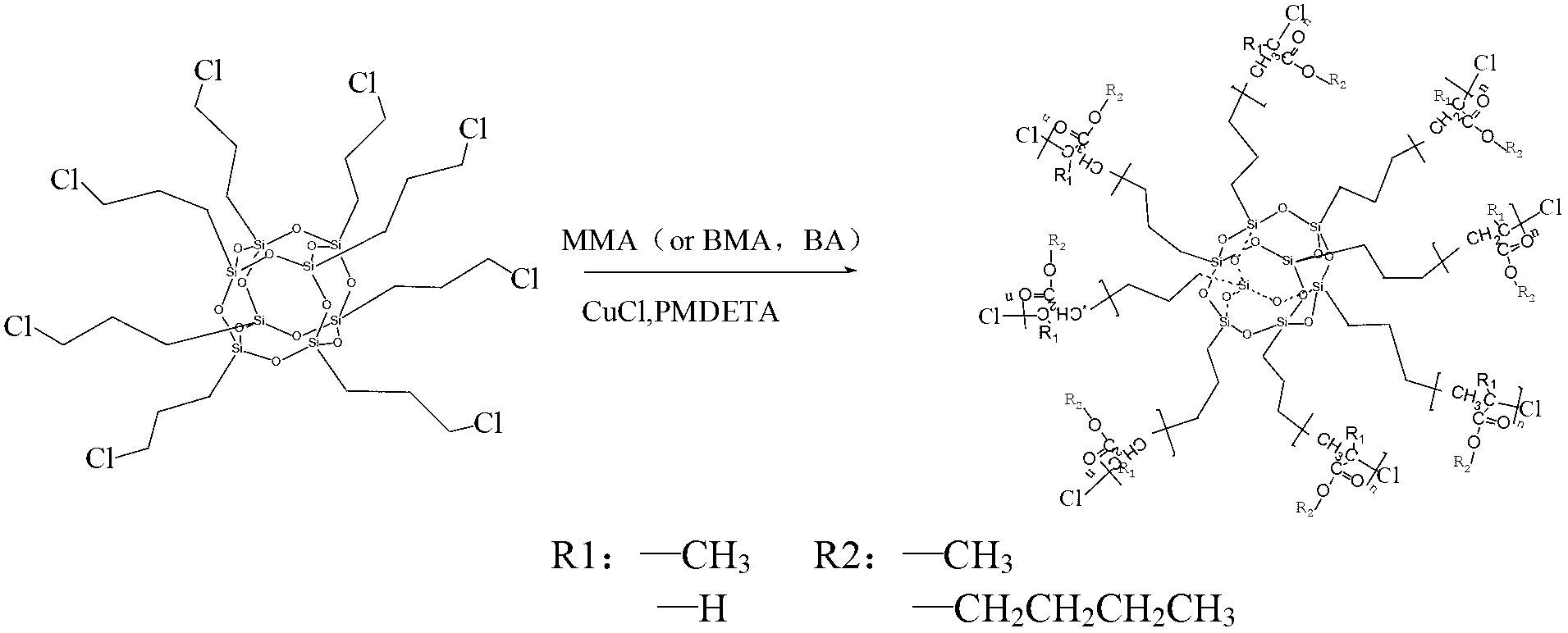

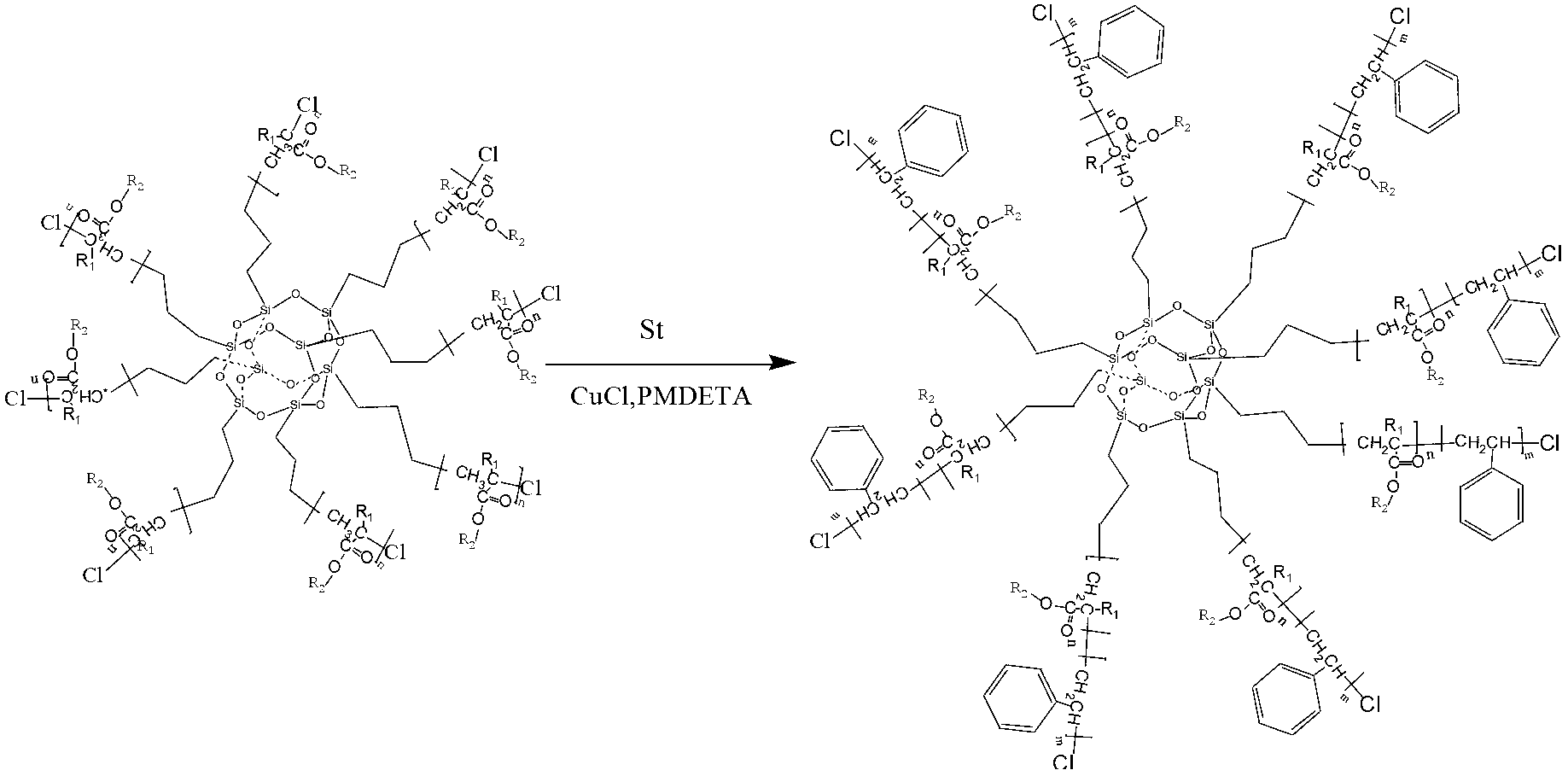

[0028] Step 2: Mix the measured octachloropropylsilsesquioxane (0.2g), pentamethyldivinyltriamine (0.15ml), cuprous chloride (0.015g), methyl methacrylate (20ml ) and toluene (20ml) were respectively added in a 100ml three-neck flask equipped with a condenser tube and a magnetic stirrer, stirred under nitrogen protection, the temperature was raised to 70°C, and then gradually increased to 110°C, and reacted to The viscosity of the system increased significantly. Dissolve the product in the container with a large amount of tetrahydrofuran to obtain a polymer solution. Pass the solution through a neutral alumina c...

Embodiment 2

[0043] (1) Step 1: Add 600ml of anhydrous methanol, 24ml of concentrated hydrochloric acid, and 30ml of γ-chloropropyltrimethoxysilane to a 1000ml three-necked flask in sequence, and continuously stir the reaction at 40°C for 5 days to obtain a white solid. Rinse several times, and dry in a vacuum oven at 50°C for 48 hours. Synthetic process such as figure 1 shown;

[0044] Step 2: Mix the measured octachloropropylsilsesquioxane (0.4g), pentamethyldivinyltriamine (0.30ml), cuprous chloride (0.030g), methyl methacrylate (40ml ) and toluene (40ml) were respectively added in a 250ml three-neck flask equipped with a condenser tube and a magnetic stirrer, stirred under nitrogen protection, the temperature was raised to 70°C, and then gradually increased to 110°C, and reacted to The viscosity of the system increased significantly. Dissolve the product in the container with a large amount of tetrahydrofuran to obtain a polymer solution. Pass the solution through a neutral alumina c...

Embodiment 3

[0059] (1) Step 1: Add 600ml of anhydrous methanol, 24ml of concentrated hydrochloric acid, and 30ml of γ-chloropropyltrimethoxysilane to a 1000ml three-necked flask in sequence, and continuously stir the reaction at 40°C for 5 days to obtain a white solid. Rinse several times, and dry in a vacuum oven at 50°C for 48 hours. Synthetic process such as figure 1 shown;

[0060] Step 2: Mix the measured octachloropropylsilsesquioxane (0.2g), pentamethyldivinyltriamine (0.15ml), cuprous chloride (0.015g), methyl methacrylate (20ml ) and toluene (20ml) were respectively added in a 100ml three-neck flask equipped with a condenser tube and a magnetic stirrer, stirred under nitrogen protection, the temperature was raised to 70°C, and then gradually increased to 110°C, and reacted to The viscosity of the system increased significantly. Dissolve the product in the container with a large amount of tetrahydrofuran to obtain a polymer solution. Pass the solution through a neutral alumina c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com