Preparation method of hot melt adhesive for multilayer oil tank

A technology of hot-melt adhesives and fuel tanks, applied in the direction of adhesives, layered products, grafted polymer adhesives, etc., can solve the problems of unstable adhesive force, poor resistance to fuel immersion, and large crystal size, etc., to achieve Cost-effective, environmentally friendly, and accelerated crystallization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

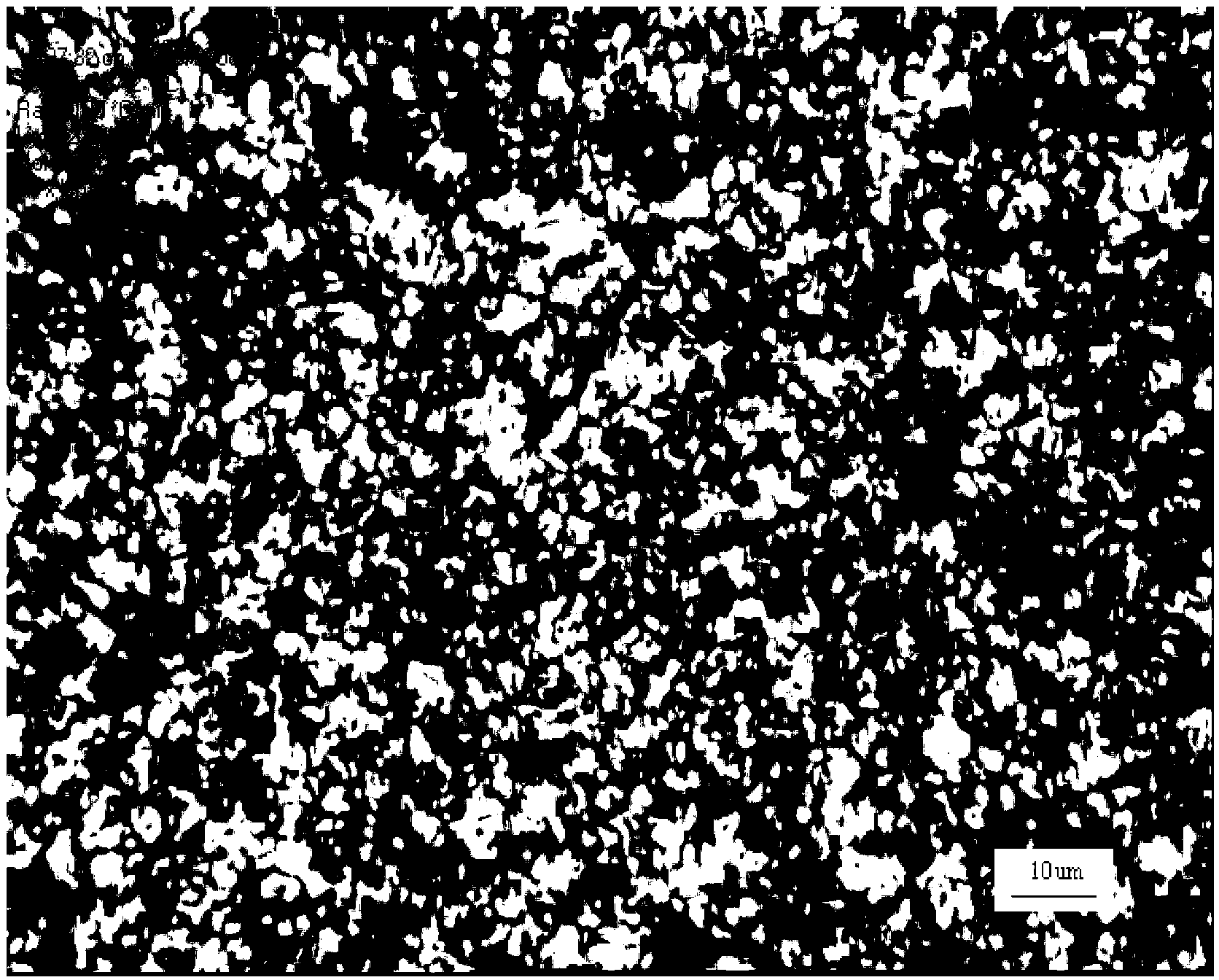

Image

Examples

Embodiment 1

[0037] The preparation method of the hot-melt adhesive for the multi-layer oil tank of the present embodiment comprises the following steps:

[0038] 1) 9.6Kg of MI 2 g / 10min (2.16Kg, 190°C) metallocene-catalyzed linear low density polyethylene, 300g of homopolypropylene, 100g of maleic anhydride, 10g of 2,5-dimethyl- Mix 2,5-bis(tert-butylperoxy)hexane and 80g of nano-silica in a high-speed mixer for 30 minutes, add 100g of mineral oil or acetone, so that a small amount of initiator can be adsorbed on the surface of the resin particles, achieve their homogeneous mixing.

[0039]2) Melt and mix the above uniformly mixed materials in a twin-screw extruder, the extrusion temperature is 210°C, the unreacted monomers are removed under a vacuum of 0.1MPa, and after cooling and pelletizing, polyethylene grafts are obtained thing.

[0040] 3) Mix 2kg of the above-mentioned polyethylene graft and 8kg of bimodal linear low-density polyethylene with an MI of 1 g / 10min (2.16Kg, 190°C) ...

Embodiment 2

[0042] The preparation method of the hot-melt adhesive for the multi-layer oil tank of the present embodiment comprises the following steps:

[0043] 1) 9.5Kg of MI 2.5 g / 10min (2.16Kg, 190°C) metallocene-catalyzed linear low-density polyethylene, 500g of random copolymerized polypropylene, 150g of maleic anhydride, 30g of dicumyl peroxide and Mix 20g of DBS (dibenzylidene sorbitol) in a high-speed mixer for 30 minutes, add 100g of mineral oil or acetone, so that a small amount of initiator can be adsorbed on the surface of the resin particles to achieve their uniform mixing.

[0044] 2) Melt and mix the above uniformly mixed materials in a twin-screw extruder, the extrusion temperature is 200°C, the unreacted monomers are removed under a vacuum of 0.1MPa, and after cooling and pelletizing, polyethylene grafts are obtained thing.

[0045] 3) Mix 2.5kg of the above-mentioned polyethylene grafts and 7.5kg of linear low-density polyethylene with an MI of 1 g / 10min (2.16Kg, 190°C...

Embodiment 3

[0047] The preparation method of the hot-melt adhesive for the multi-layer oil tank of the present embodiment comprises the following steps:

[0048] 1) Add 9.8Kg of MI to 4 g / 10min (2.16Kg, 190°C) high-density polyethylene, 200g of homopolypropylene, 200g of maleic anhydride, 20g of benzoyl peroxide (BPO) and 80g of p-hydroxy Benzoic acid is mixed in a high-speed mixer for 30 minutes, and 100g of mineral oil or acetone can be added, so that a small amount of initiator can be adsorbed on the surface of the resin particles to achieve their uniform mixing.

[0049] 2) Melt and mix the above uniformly mixed materials in a twin-screw extruder, the extrusion temperature is 190°C, the unreacted monomers are removed under a vacuum of 0.1MPa, and after cooling and pelletizing, polyethylene grafts are obtained thing.

[0050] 3) Mix 1.5kg of the above-mentioned polyethylene grafts and 8.5kg of bimodal linear low-density polyethylene with an MI of 1g / 10min (2.16Kg, 190°C) in a high-spe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com