Thermosetting crosslinked cycloolefin resin film and manufacturing process therefor

A cycloolefin resin and a manufacturing method technology, which are applied in the directions of printed circuit manufacturing, electric solid state devices, semiconductor/solid state device parts, etc., can solve the problem that the resin does not have mold releasability and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1~9 and comparative example 1~4

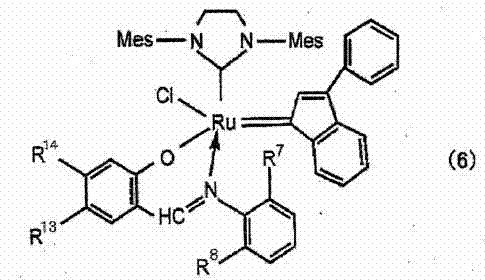

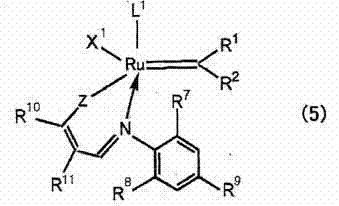

[0123] Prepare the polymers shown in Table 1. A specific polymer containing an alkyl (meth)acrylate unit having an alkyl group having 3 or more carbon atoms having the mass shown in Table 2 and Table 3 was dissolved in dicyclopentadiene to obtain a reaction stock solution. Then, add the ruthenium catalyst with the structure of formula (7) shown in Table 2 and Table 3 to the above reaction stock solution, mix with a line mixer, and then heat Cast film formation was carried out on a carrier film made of polyethylene terephthalate. Then, it heated at 200 degreeC for 5 minutes in nitrogen atmosphere, and obtained the release film. The results are shown in Table 2 and Table 3.

[0124] [chemical 5]

[0125]

[0126] [Table 1]

[0127]

[0128] Polymer 1: Actoflow (registered trademark) UT-1001 manufactured by Soken Scientific Co., Ltd., the terminal is modified with a hydroxyl group, and the hydroxyl value is 57±2.

[0129] Polymer 2: Refer to Production Example 1

[01...

manufacture example 1

[0135] A monomer mixture consisting of 65% of 2-ethylhexyl acrylate and 35% of styrene and 0.03 part of 2,2'-azobisisobutyronitrile were dissolved in 700 parts of ethyl acetate in the reactor. After nitrogen substitution, polymerization reaction was performed at 80° C. for 6 hours. The polymerization conversion rate was 95%. The obtained copolymer was dried under reduced pressure, ethyl acetate was evaporated, and a viscous solid copolymer was obtained. The weight average molecular weight of the copolymer was 400,000, and the weight average molecular weight / number average molecular weight was 3.1.

manufacture example 2

[0137] A monomer mixture consisting of 25% n-butyl acrylate and 75% styrene and 0.03 part of 2,2'-azobisisobutyronitrile were dissolved in 700 parts of ethyl acetate in the reactor. After nitrogen substitution, polymerization reaction was performed at 80° C. for 6 hours. The polymerization conversion rate was 95%. The obtained copolymer was dried under reduced pressure, ethyl acetate was evaporated, and a viscous solid copolymer was obtained. The copolymer had a weight average molecular weight of 40,000.

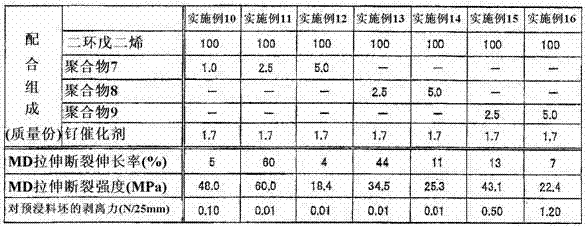

[0138] [Table 2]

[0139]

[0140] [table 3]

[0141]

[0142] Ruthenium catalyst: VC843 manufactured by RIMTEC Co., Ltd.

[0143] The release films of Examples 1 to 9 had high releasability and mechanical strength. The release film of Comparative Example 1 obtained by ring-opening metathesis polymerization of a polymerizable composition containing no polymer containing an alkyl group having 3 or more carbon atoms ( Alkyl meth)acrylate units. Although the alkyl ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com