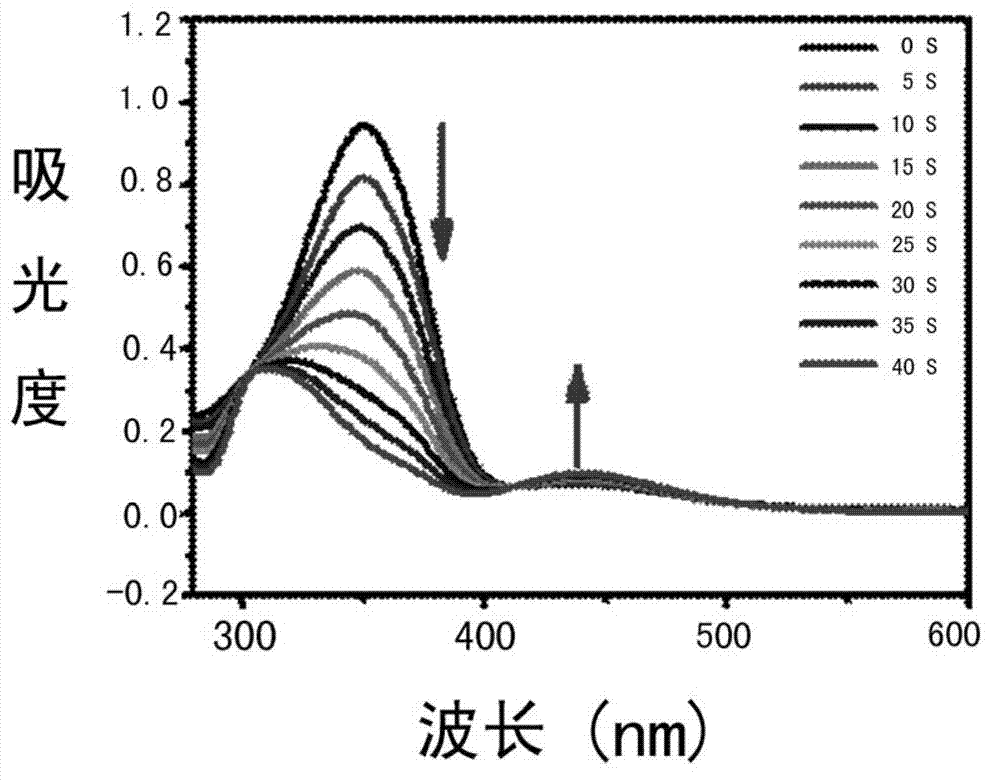

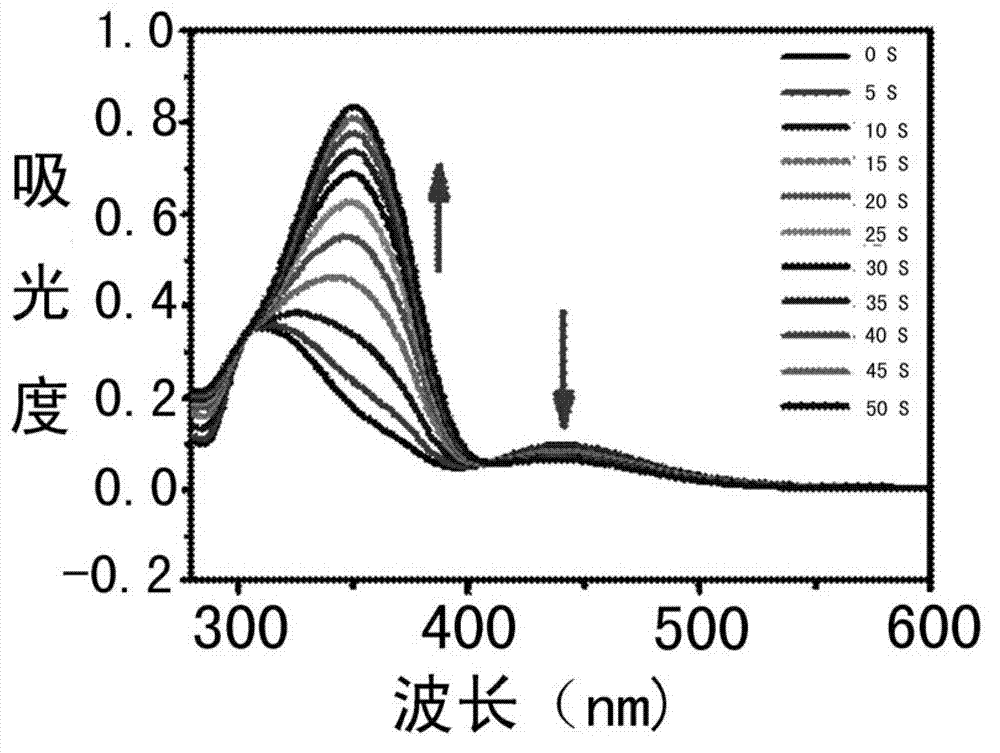

Preparation method of light/pH-sensitive amphiphilic azobenzene polymer micelles

A technology of amphiphilic polymers and polymers, applied in medical preparations with non-active ingredients, medical preparations containing active ingredients, pharmaceutical formulations, etc., to achieve the effect of broad application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

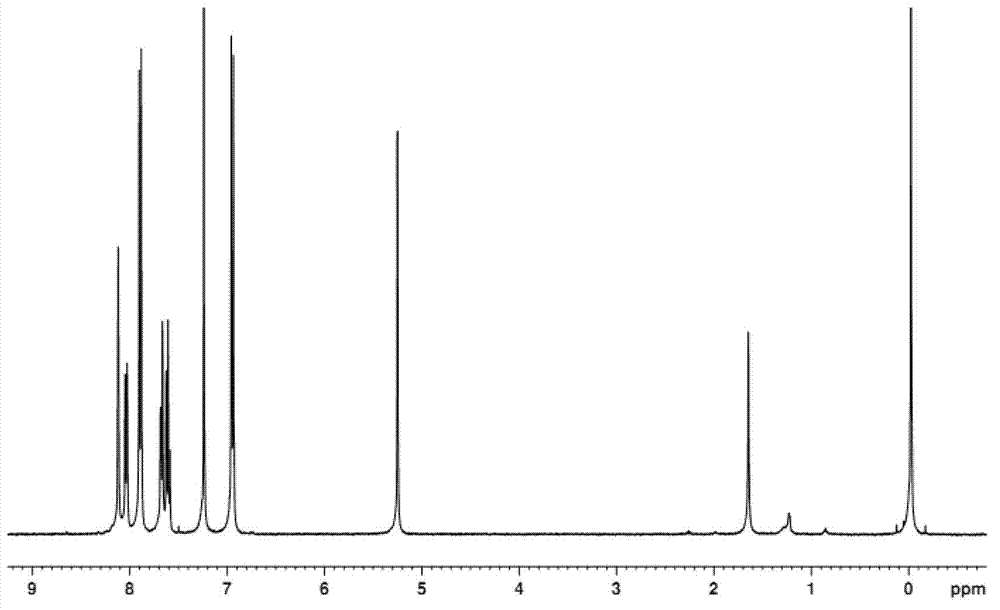

Embodiment 1

[0035] Preparation of m-trifluorotoluene azophenol: m-trifluoromethylaniline (3.22g, 2.47ml, 0.02mol) was mixed with concentrated hydrochloric acid (36%, 6ml) and deionized water (12ml) to make a paste, and the temperature was controlled around 0°. Slowly add a cold solution of sodium nitrite (0.0202mol, 1.394g) dropwise under stirring, stir until the solution turns the starch potassium iodide blue, add a small amount of urea to destroy the excess sodium nitrite, filter the product, and take the filtrate to cool for later use. Phenol (1.88g, 0.02mol) was dissolved in sodium hydroxide (1.2g, 0.03mol) aqueous solution (10ml). After the dissolution was completed, the pH was adjusted to about 10 with dilute hydrochloric acid, and the temperature was controlled at about 0°. The aforementioned diazonium salt solution was added dropwise into the phenol solution, and during the dropwise addition, the pH was kept at about 10 by adjusting with saturated sodium carbonate solution. Conti...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com