High-performance multiple azo brown reactive dye as well as synthesis and application of mixture thereof

A technology of reactive dyes and polyazo, applied in the direction of reactive dyes, azo dyes, organic dyes, etc., can solve the problems of reducing printing and dyeing costs, and achieve the effects of energy saving, excellent wet fastness, and good level dyeing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

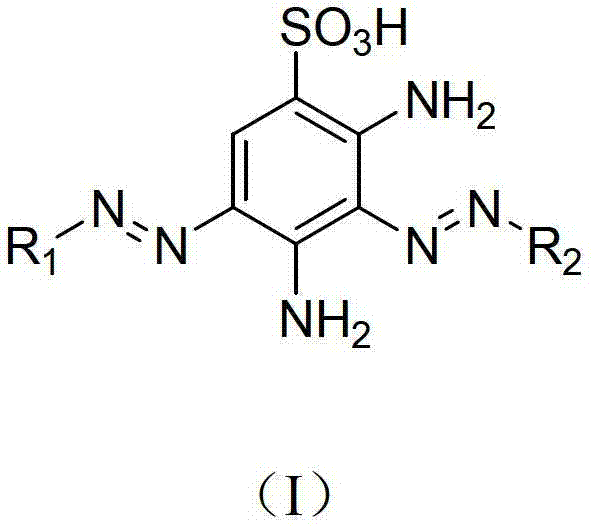

[0037] The preparation of embodiment 1 polyazo brown reactive dye I-1

[0038] In a 1000ml beaker, add 150 parts of water, 28.1 parts of para-ester, 0.1 part of dispersant, stir and beat for 2 hours, add 30 parts of 30% hydrochloric acid, and add 23 parts of 30% sodium nitrite at 0-5 °C The solution was subjected to diazotization reaction for 2 hours. After reaching the end point, sulfamic acid was added to destroy excess nitrous acid, then 188 parts of m-phenylenediaminesulfonic acid solution was added, the temperature was raised to 10-15°C, and the pH was adjusted with 15% sodium acetate solution. =1~2, react for 4~6 hours, when there is no diazonium salt, it is the end point, and set aside.

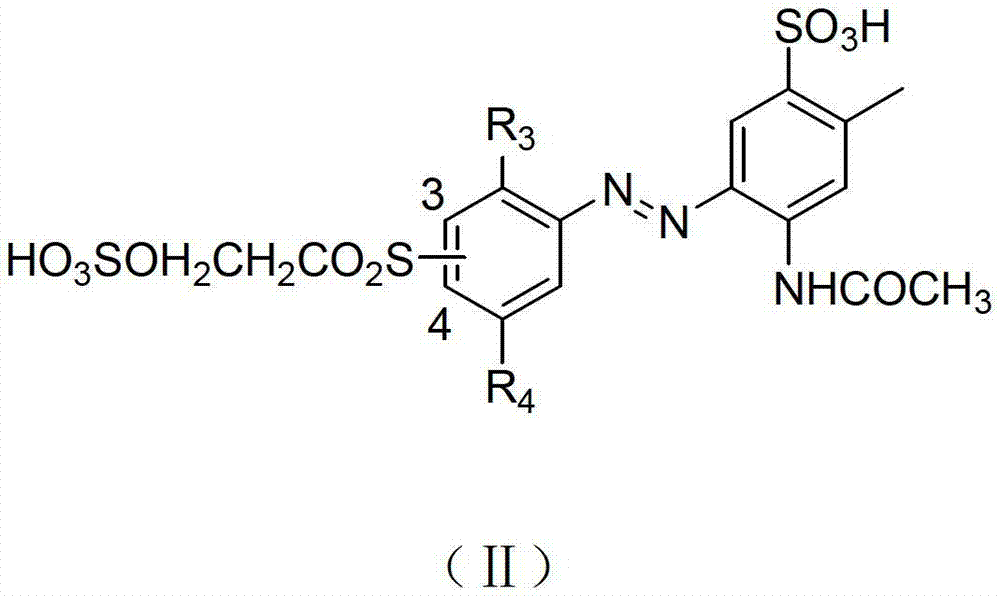

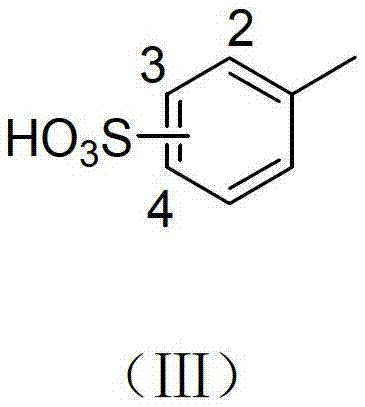

[0039] In a 1000 ml beaker, add 350 parts of water, 52.3 parts of the compound of formula Ⅱ-1 (R 3 , R 4 hydrogen), 0.1 part of dispersant, stir until fully dissolved, add 30 parts of 50% sulfuric acid, add 23 parts of 30% sodium nitrite solution at 0-5°C for diazotization reaction f...

Embodiment 2

[0041] The preparation of embodiment 2 polyazo brown reactive dyes 1-2

[0042] In a 1000 ml beaker, add 350 parts of water, 52.3 parts of the compound of formula Ⅱ-1 (R 3 , R 4 hydrogen), 0.1 part of dispersant, stir until fully dissolved, add 30 parts of 50% sulfuric acid, add 23 parts of 30% sodium nitrite solution at 0-5°C for diazotization reaction for 2 hours, and add Sulfamic acid destroys excess nitrous acid, add 188 parts of m-phenylenediamine sulfonic acid solution, heat up to 10-15°C, adjust pH=1-2 with 15% sodium acetate solution, react for 4-6 hours, no diazo Salt time is the end point, set aside.

[0043]In a 1000ml beaker, add 150 parts of water, 28.1 parts of para-ester, 0.1 part of dispersant, stir and beat for 2 hours, add 30 parts of 30% hydrochloric acid, and add 23 parts of 30% sodium nitrite at 0-5 °C The solution was subjected to diazotization reaction for 2 hours, and after reaching the end point, sulfamic acid was added to destroy excess nitrous aci...

Embodiment 3-11

[0045] The preparation of embodiment 3-11 polyazo brown reactive dyes I-3~I-11

[0046] Referring to the method of Example 1, dyes I-3 to I-6 can be obtained, and the polyazo brown reactive dyes of I-7 to I-12 can be obtained by changing the coupling sequence and raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com