Method for testing indium content in epitaxial layer of InGaN chip

A technology of element content and test method, applied in the direction of color/spectral characteristic measurement, etc., can solve problems such as difficulty in wafer sample processing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] (1) Sample pretreatment

[0032] Take a 10mm×10mm square InGaN (In 0.12 Ga 0.88 N) Wafer, soak the sample with dilute hydrochloric acid for 10 minutes, rinse it with deionized water, soak it with analytical grade acetone for 5 minutes, and accurately weigh the sample with a balance to 715.558mg (m 0 ).

[0033] (2) Etching

[0034] Place the processed InGaN wafer sample horizontally in a platinum crucible with the epitaxial layer facing up, spread 0.02g of powdered analytical pure sodium hydroxide evenly on the surface of the sample, heat until the sodium hydroxide is completely melted, etch for 30s, and cool , dissolve the etchant with 15ml deionized water to obtain the etchant, and the surface of the wafer is 340 There is no substrate peak in the nm photoluminescence spectrum; spread 0.01g of sodium hydroxide on the surface of the wafer, repeat the above operation, and the photoluminescence spectrum is 340 A substrate peak appeared at nm, stop etching, the weight...

Embodiment 2

[0043] (1) Preparation of etching solution

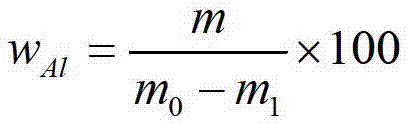

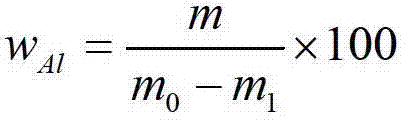

[0044] Take a 15mm×15mm square indium gallium nitride wafer (In0.09Ga0.91N), weighing 532.115mg (m 0 ), the sample is processed by alkali fusion etching, and 0.04g of analytically pure sodium hydroxide is spread on the wafer surface, heated until the sodium hydroxide is completely melted, and after 20 seconds of etching once, the photoluminescence spectrum 340 The substrate peak appeared at nm, and the etching was completed, weighing 531.236mg (m 1 ), then the mass of the etched epitaxial film is 0.879mg (m 0 —m 1 ), with 3mol L -1 Sulfuric acid to adjust the pH of the etching solution to 1, and then use 2mol L -1 Aqueous ammonia to adjust the PH to 3, constant volume.

[0045] (2) Preparation of complexation chromogenic solution

[0046] Take 30ml of etching solution in a 100ml volumetric flask, and add 5.7ml of sulfuric acid (3mol L -1 ), 3ml of potassium iodide solution (1g / ml), 0.5ml of sodium thiosulfate solution (20g / l)...

PUM

| Property | Measurement | Unit |

|---|---|---|

| absorbance | aaaaa | aaaaa |

| absorbance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com