Method for treating garlic processing waste water

A technology of garlic processing wastewater and treatment method, which is applied in the directions of water/sewage multi-stage treatment, water/sludge/sewage treatment, dehydration/drying/concentrated sludge treatment, etc. Improve biochemical performance, improve efficiency, and ensure the effect of effluent quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

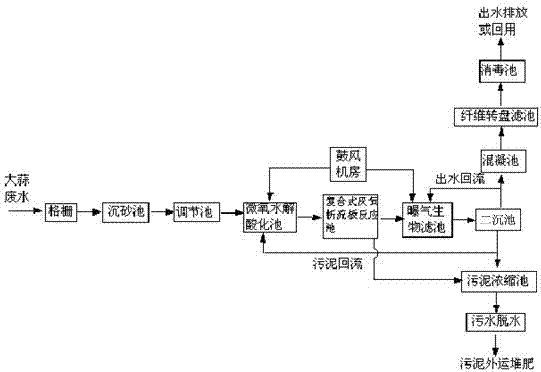

[0025] In the figure, the implementation steps of this garlic processing wastewater treatment method are:

[0026] (1) The waste water enters the grid first, the installation angle of the grid is 60°, and the gap between the grid bars is controlled at 6mm. When the waste water flows through the grid, the coarse debris in the waste water is removed;

[0027] (2) The effluent enters the cyclone grit chamber to remove inorganic sand particles, and the hydraulic retention time is 2 minutes;

[0028] (3) The effluent enters the regulating tank to adjust the water quality and quantity, and the hydraulic retention time is 9 hours;

[0029] (4) The effluent enters the microaerobic hydrolysis acidification tank, the return sludge is mixed with the garlic processing wastewater, and the mixed solution is subjected to microaerobic aeration to degrade the refractory organic matter in the wastewater into easily degradable small molecule organic matter, improving the biochemical pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com