Method for synthesizing tetra-glycylglycine

A synthetic method and technology of tetraglycine peptide, applied in the preparation method of peptides, chemical instruments and methods, peptides, etc., can solve the problems of strict impurity requirements, poor solubility, low yield, etc., and achieve product qualification rate High, good solubility, high yield effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

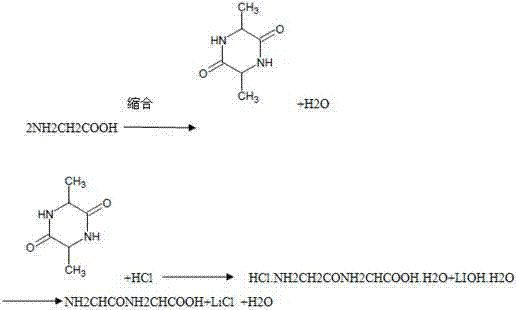

[0018] Add 50L ethylene glycol and 10KG glycine into a 100L oil bath, stir and heat up to 170-175°C for 45-60 minutes, cool to 60°C, add 10L water, cool to room temperature and centrifuge to obtain 8KG crude product, which is hydrolyzed by adding 15L hydrochloric acid Cool and centrifuge for 1-2 minutes to obtain 7KG solid, add lithium hydroxide solution to adjust pH5.5-6, add about 0.2KG activated carbon, refine and decolorize, add 2-3 times alcohol to filter to obtain double 5KG crude glycine peptide, and then water Recrystallize, add 2-3 times of alcohol, filter and wash until the chlorine is qualified, and dry to obtain 3.5KG of glycylglycine (content 99.2%). In this example, the reaction formula is as follows:

[0019]

Embodiment 2

[0021] Add 50L1. centrifuged ethylene glycol mother liquor and 10KG glycine to a 100L oil bath, stir and heat up to 170-175°C for 45-60 minutes, cool to 60°C, add 10L water, cool to room temperature and centrifuge to obtain 8.2KG crude product, crude product Add 20L 2N lithium hydroxide aqueous solution and keep it warm at 30-40°C for 30-60 minutes, neutralize the pH5.5-6.0 with hydrochloric acid, add about 0.2KG activated carbon to refine and decolorize, add 2-3 times of alcohol to filter to obtain double 5KG glycine peptide The crude product was recrystallized with water, added 2-3 times of alcohol, filtered, washed, and dried to obtain 3.8KG (content 99.0%) of glycylglycine. In this example, the reaction formula is as follows:

[0022]

[0023] 2. Synthesis of triglycyl peptide

[0024] See the reaction below:

[0025]

[0026]

[0027]

Embodiment 3

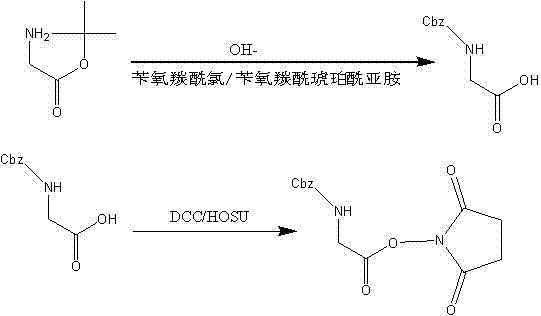

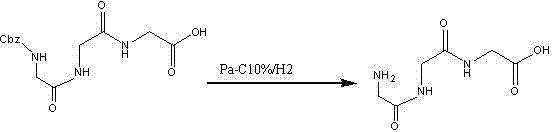

[0029]Add 50% of water and 15KG of glycine into a 100L reaction tank, use 4N aqueous sodium hydroxide solution to maintain the pH=9-10, keep the temperature at 5-10°C, add 37KG of methyl chloride benzyl dropwise, and naturally heat up the reaction after the dropwise addition , TLC to test the reaction until the reaction of benzyl chloroformate is complete, add 30L ethyl acetate, neutralize the pH2.2-2.5 with hydrochloric acid, stir and crystallize, centrifugally wash and dry to obtain 27KG Z-glycine; Add 12KG HOSU and 23KG DCC, react at 25-30°C for 36 hours, spot on TLC plate until the reaction is complete, and filter off the solid to obtain 1,20L Z-GLY-OSU / ethyl acetate solution; -GLY-OSU / ethyl acetate solution was dropped into (13 KG glycylglycyl peptide, 50 L water, 17 KG sodium bicarbonate mixed solution), reacted at room temperature for 24 hours, TLC plated until Z-GLY-OSU reacted 98. 0% or more (liquid phase monitoring), the ethyl acetate layer was separated at the end o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com