System for producing clean energy

A clean energy and gasification device technology, applied in the system field of clean energy production, can solve problems such as impact, ecological system life hazard, ecosystem damage, etc., and achieve the effects of increasing economic benefits, reducing product costs, and improving thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

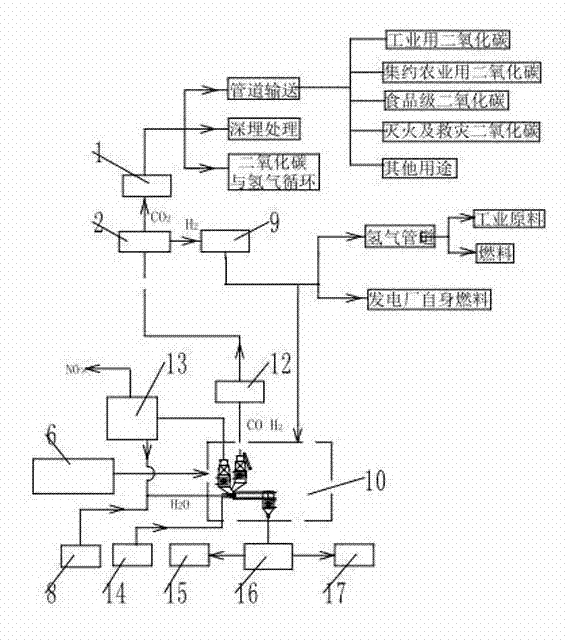

Embodiment 1

[0023] The system of clean energy production of the present invention is as figure 1 As shown, it includes gasification device 10, coal stockyard 6, shift reaction and hydrogen purification device 2, gas purification device 12, hydrogen delivery equipment 9, carbon dioxide storage device 1, nitrogen oxide compound treatment and water vapor recovery device 13, water vapor storage tank 8 , oxygen and oxygen-enriched air supply equipment 14 , heavy metal treatment equipment 15 , slag separation equipment 16 , cement plant 17 and water vapor storage tank 8 . The gasification device is provided with feeding equipment 21, gasification equipment, fuel gas inlet, steam inlet, flue gas outlet, gasification gas outlet and waste residue outlet. The feeding equipment is connected with the coal yard, and the steam inlet is connected with the steam storage tank. The conversion reaction and hydrogen purification device is provided with a gas inlet, a hydrogen outlet and a carbon dioxide out...

Embodiment 2

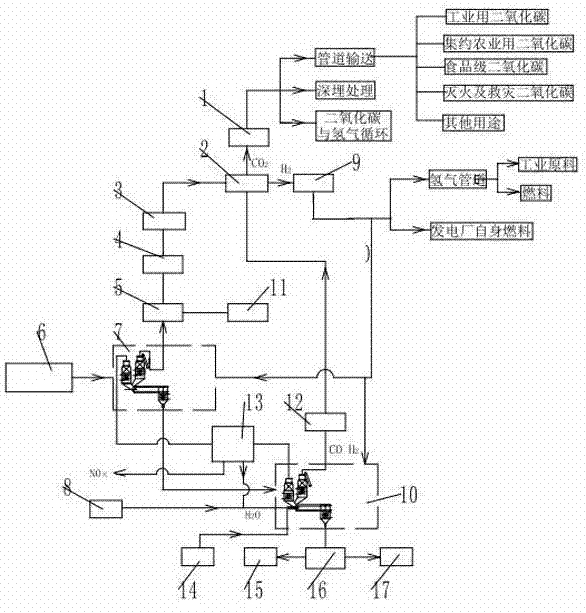

[0026] Another embodiment of the present invention is as figure 2 As shown, the clean energy production system also includes a coking unit 7 , a cracking unit 3 , a gas purification unit 4 , a tar separation unit 5 and a tar and chemical utilization unit 11 . The coking device is provided with feeding equipment 21, flue gas outlet, fuel gas inlet, pulverized coal nozzle, coking gas outlet and coke outlet. The feeding equipment is connected to the coal stockyard 6, the coke outlet is connected to the feeding equipment of the gasification device 10, the coking gas outlet is connected to the tar separation device 5, and the flue gas outlet is connected to the flue gas of the nitrogen oxide treatment and water vapor recovery device 13. The gas inlet and the fuel gas inlet are connected with the hydrogen delivery equipment 9 . The tar separation device is provided with a liquid outlet and a gas outlet, the liquid outlet is connected to the tar and chemical utilization device 11, ...

Embodiment 3

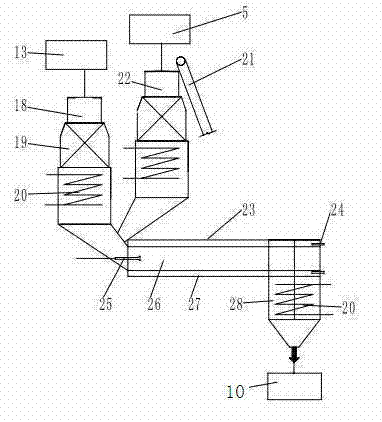

[0029] Another form of the gasification device of the clean energy production system of the present invention is as Figure 5 As shown, a common rotary kiln 32, a cooler 28 and a raw material preheater 22 are provided. Common rotary kiln is provided with hydrogen and oxygen nozzle 31. The raw material preheater 22 is provided with a heat exchanger 19, a power generation steam coil 20, an upper port, a lower port and a gasification outlet. The upper port is connected to the feeding equipment 21, the lower port is connected to the kiln chamber of a common rotary kiln, and the gasification outlet is connected to the gas purification device 12. The cooler is provided with a power generation steam coil 20, the upper port of the cooler is connected with a common rotary kiln, and the lower port is connected with a slag separation device 16. Other processes and equipment are the same as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com