Air energy heat cycle preserved fruit drying apparatus and automatic temperature control method thereof

A technology for drying dried fruits and air energy heating, which is applied to auxiliary controllers with auxiliary heating devices, uses electric methods for temperature control, and preserves fruits/vegetables through dehydration, etc., which can solve the problem of low continuous work efficiency and high energy consumption. problem, to achieve the effect of low production cost, low energy consumption and good preservation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

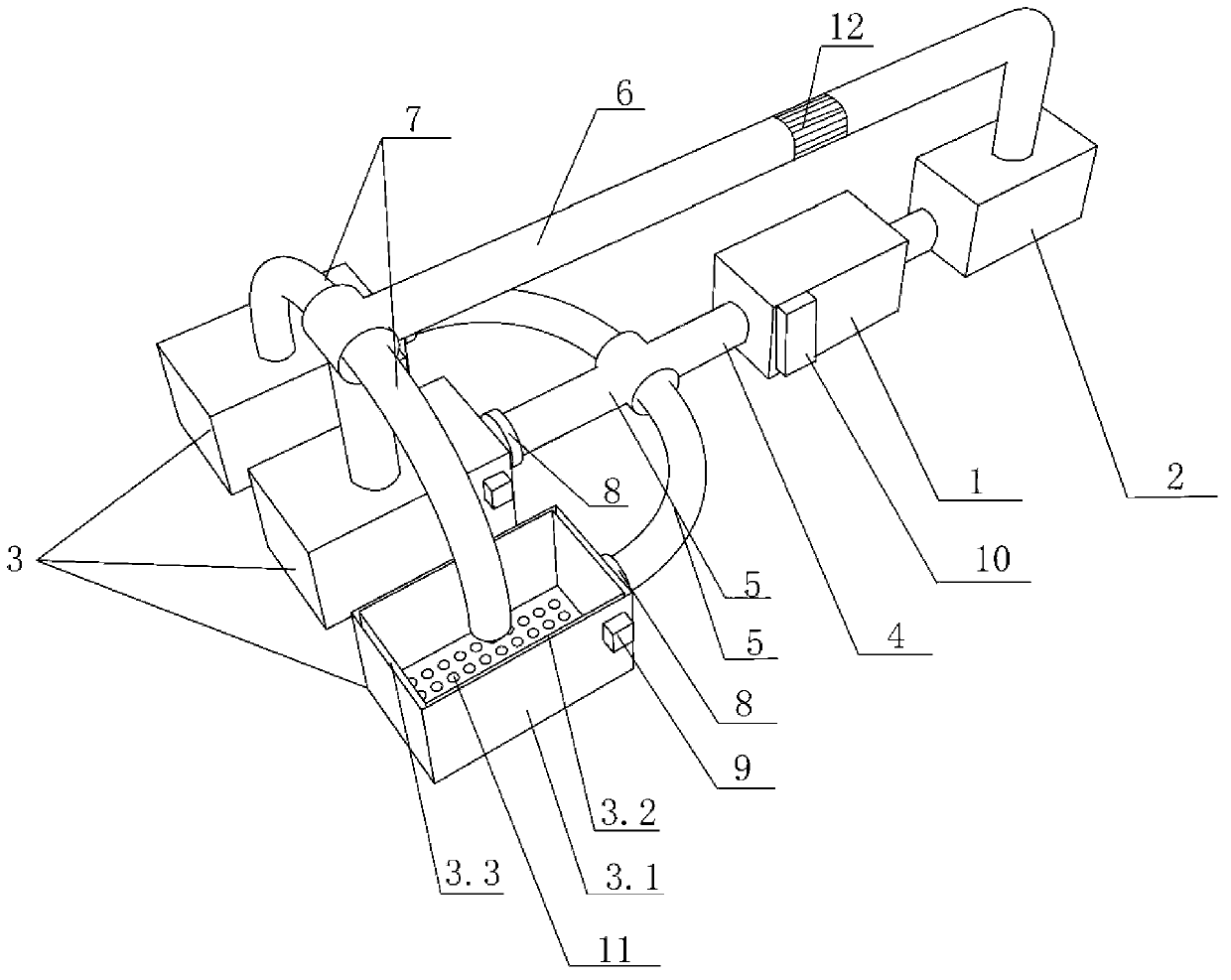

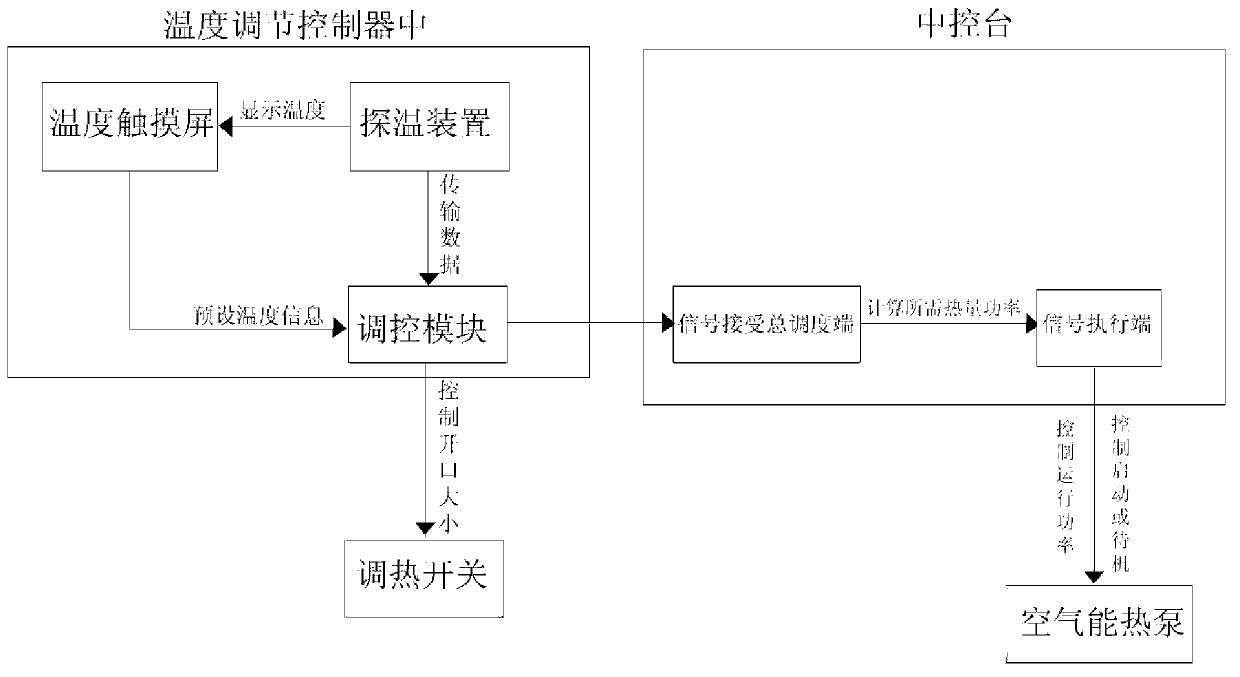

[0031] Such as Figure 1-2As shown, it is a structural schematic diagram of the present invention. The air energy heat cycle dried fruit drying device includes an air energy heat pump 1, a dehumidifier 2 and three drying rooms 3, and the end of the air energy heat pump 1 is provided with a total heat flux Pipe 4, which connects three sub-heat flow pipes 5 in series, and the three heat-flow pipes 5 connected in series are respectively connected to the corresponding drying room 3, and the drying room 3 is divided into two layers, including the outer layer 3.1 of the drying room and the drying room Inner layer 3.2, wherein, a cavity 3.3 is formed between the outer layer 3.1 of the drying room and the inner layer 3.2 of the drying room, and the heat pipe 5 is connected to the outer layer 3.1 of the drying room, while the bottom of the inner layer 3.2 of the drying room is provided with a plurality of ventilation channels. thermal hole11. At the top of the drying room 3, the chann...

Embodiment 2

[0037] The difference from Example 1 is that there are 8 ovens 3 in total, and the rest of the working principles are the same as those in Example 1.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap