High purity full porous silica gel-bonded chromatography immobile phase preparation method

A chromatographic stationary phase, fully porous technology, applied in the application of high performance liquid chromatography packing, the preparation of new high-purity fully porous silica gel bonded chromatographic stationary phase, can solve the problem of reducing surface activity, not too high coverage, not capping reaction Complete and other problems, to achieve the effect of improving chromatographic separation performance, expanding the separation range, and widening the separation range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

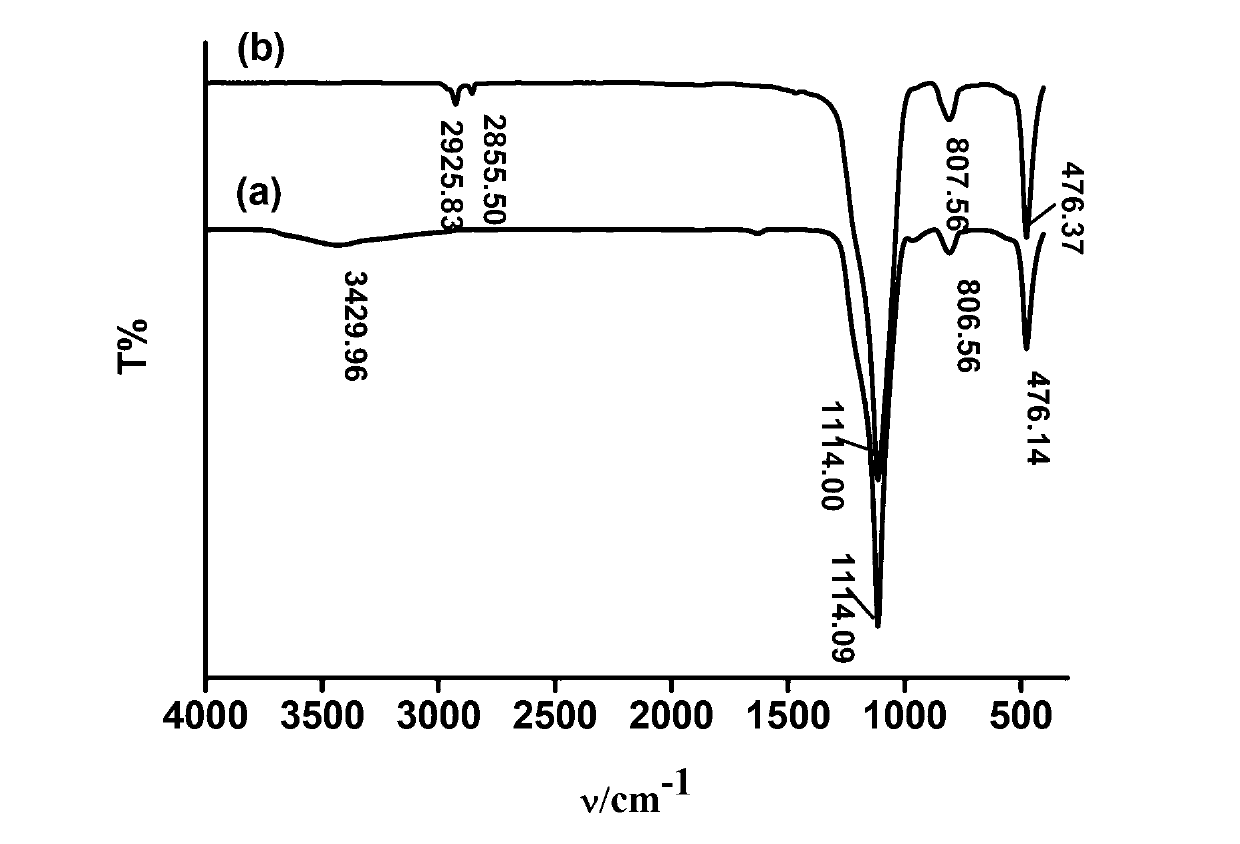

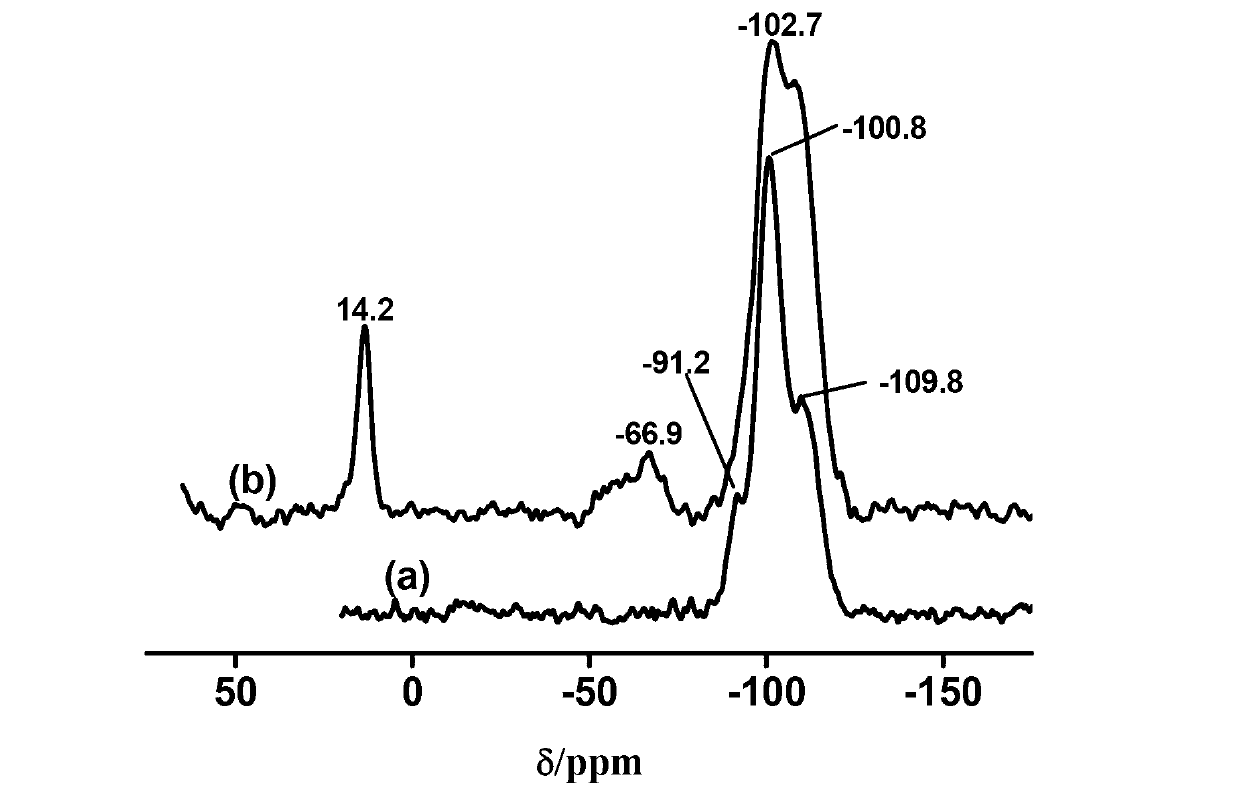

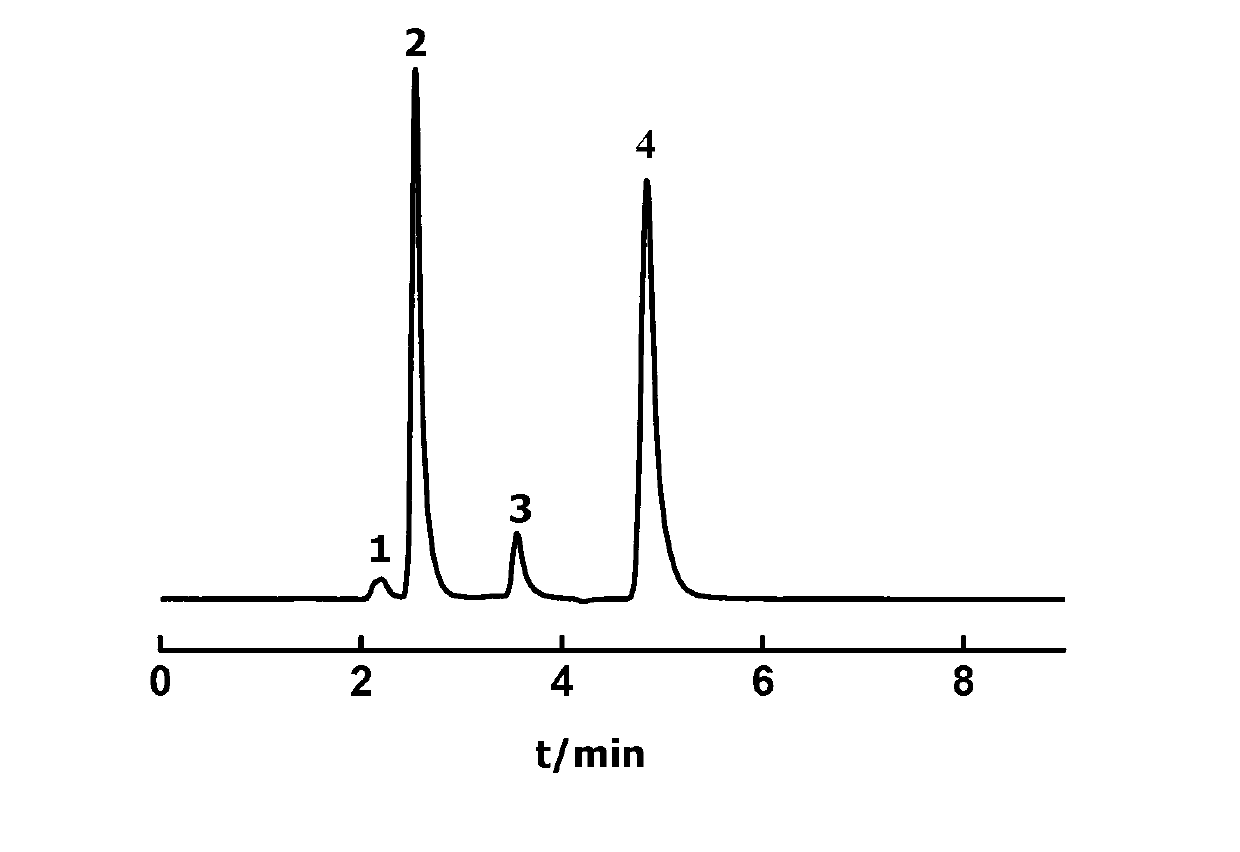

[0033] A. Take a certain amount of self-made high-purity porous spherical silica gel in a conical flask, add nitric acid with a volume fraction of 10% according to the ratio of 30ml nitric acid: 1g silica gel, perform suction filtration after ultrasonication for 1 hour, wash with water until neutral, and bake at 100°C dry reserve;

[0034] B. Take a certain amount of acidified silica gel in step A and add it to a reaction vessel with a condensing device, add dry toluene solvent at the ratio of 40ml toluene: 1g silica gel under constant stirring, heat and reflux at 110°C for 2 hours, then press 0.8 Add p-toluenesulfonic acid catalyst at the ratio of 1g p-toluenesulfonic acid: 1g silica gel, stir for 10 minutes, then add silylating agent according to the ratio of 0.2g octadecyldimethylmethoxysilane: 1g silica gel, heat and reflux for 9 hours , stop heating, cool under stirring for 30 minutes, wash with toluene and methanol in turn, and vacuum dry at 120°C for 10 hours for later ...

Embodiment 2

[0041] A. Take a certain amount of self-made high-purity porous spherical silica gel in a conical flask, add nitric acid with a volume fraction of 20% according to the ratio of 20ml nitric acid: 1g silica gel, perform suction filtration after ultrasonication for 1.5 hours, wash with water until neutral, and bake at 90°C dry reserve;

[0042] B. Take a certain amount of acidified silica gel in step A and add it to a reaction vessel with a condensing device, add dry toluene solvent at the ratio of 30ml toluene: 1g silica gel under constant stirring, heat and reflux at 110°C for 3 hours, press Add p-toluenesulfonic acid catalyst at the ratio of 0.5g p-toluenesulfonic acid: 1g silica gel, stir for 12 minutes, then add silylating agent according to the ratio of 0.15g octadecyldimethylmethoxysilane: 1g silica gel, heat to reflux for 8 hour, stop heating, stir and cool for 30 minutes, wash with toluene and methanol successively, and vacuum dry at 100°C for 11 hours for later use;

...

Embodiment 3

[0047] A. Take a certain amount of self-made high-purity porous spherical silica gel in a conical flask, add nitric acid with a volume fraction of 30% according to the ratio of 10ml nitric acid: 1g silica gel, perform suction filtration after ultrasonication for 1 hour, wash with water until neutral, and bake at 80°C dry reserve;

[0048] B. Take a certain amount of acidified silica gel in step A and add it to a reaction vessel with a condensing device, add dry toluene solvent at the ratio of 20ml toluene: 1g silica gel under constant stirring, heat and reflux at 110°C for 4 hours, then press 0.3 Add p-toluenesulfonic acid catalyst at the ratio of 1g p-toluenesulfonic acid: 1g silica gel, stir for 15 minutes, then add silylating agent according to the ratio of 0.1g octadecyldimethylmethoxysilane: 1g silica gel, heat and reflux for 9 hours , stop heating, cool under stirring for 30 minutes, wash with toluene and methanol in turn, and vacuum dry at 80°C for 12 hours for later us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com