Air electrode for lithium-air battery and preparation method for air electrode

An air electrode and air battery technology, applied in battery electrodes, circuits, electrical components, etc., can solve the problems of poor charge and discharge utilization, fewer cycles, and low channel utilization, and achieve improved rate performance and easy large-scale production. , the effect of eliminating the preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

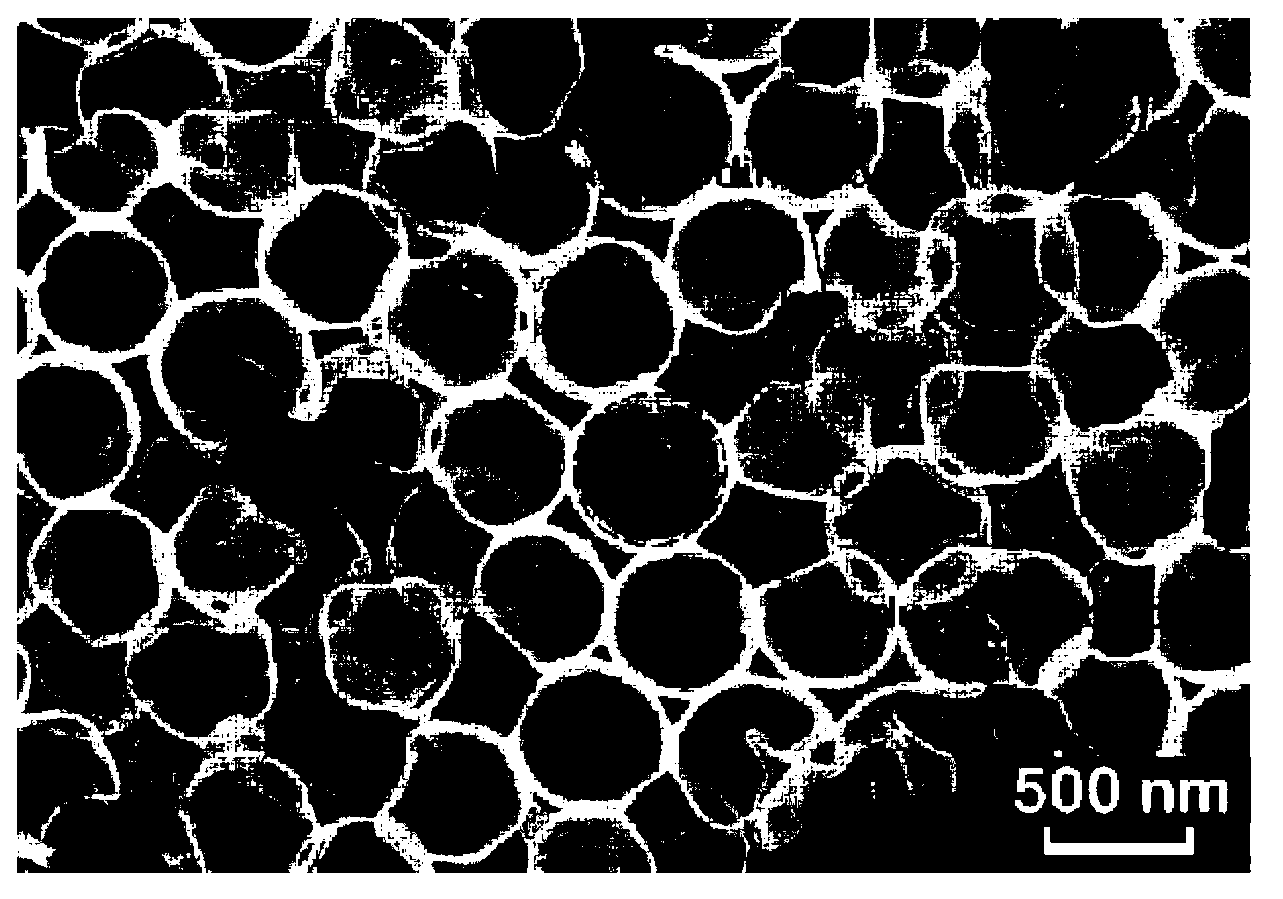

[0048] (1) Add 15mL of concentrated ammonia water, 150mL of ethanol, 15mL of deionized water, and 15mL of ethyl orthosilicate into a round bottom flask and stir for 5 hours. The obtained product is centrifuged, washed and dried at 100°C to obtain Highly dispersed silica spheres.

[0049] (2) Add 6mL of 3-mercaptopropyltrimethoxysilane and 2.0g of silicon spheres to 200mL of toluene in sequence, reflux at 110°C for 10 hours, then cool at room temperature, centrifuge, wash and dry to obtain mercaptosilane spheres.

[0050] (3) The two electrodes are carbon paper and steel sheet respectively, the distance between the electrodes is 0.5cm, the electrolyte is mercaptosilicate silicon balls dispersed in a mixed solvent of acetone and methanol with a volume ratio of 1:1, and the electrophoresis voltage is 15V to obtain mercaptosilicate Silicon spherical carbon paper electrode.

[0051] (4) Soak the mercapto-silicon spherical carbon paper electrode in a chloroform solution of palladiu...

Embodiment 2

[0058] (1) Add 15mL of concentrated ammonia water, 300mL of ethanol, 75mL of deionized water, and 30mL of ethyl orthosilicate into a round bottom flask and stir for 10 hours. The obtained product is centrifuged, washed and dried at 100°C to obtain Highly dispersed silica spheres.

[0059] (2) Add 30mL of mercaptopropionic acid and 2.0g of silicon spheres to 200mL of toluene in turn, reflux at 110°C for 12 hours, then cool at room temperature, centrifuge, wash, and dry to obtain mercaptosilica spheres.

[0060] (3) The two electrodes are carbon paper and steel sheet respectively, the distance between electrodes is 2.0cm, the electrolyte is mercaptosilicate silicon balls dispersed in the mixed solvent of acetone and methanol with a volume ratio of 10:1, and the electrophoresis voltage is 25V to obtain mercaptosilicate Silicon spherical carbon paper electrodes.

[0061] (4) Soak the mercapto-silicon spherical carbon paper electrode in the chloroauric acid solution with a mass co...

Embodiment 3

[0064] (1) Add 15mL of concentrated ammonia water, 200mL of ethanol, 45mL of deionized water, and 15mL of ethyl orthosilicate into a round bottom flask and stir for 18 hours. The obtained product is centrifuged, washed and dried at 100°C.

[0065] (2) Add 20mL of mercaptoethanol and 2.0g of silicon spheres to 200mL of toluene in turn, reflux at 110°C for 15 hours, then cool at room temperature, centrifuge, wash, and dry to obtain mercaptosilane spheres.

[0066] (3) The two electrodes are carbon paper and steel sheet respectively, the distance between electrodes is 1.0cm, the electrolyte is mercaptosilicate silicon balls dispersed in a mixed solvent of acetone and methanol with a volume ratio of 1:10, and the electrophoresis voltage is 20V to obtain mercaptosilicate Silicon spherical carbon paper electrodes.

[0067] (4) Soak the mercaptosilicon spherical carbon paper electrode in manganese acetate solution with a mass concentration of 8% for half an hour, filter, dry, and cal...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com