Application of covalent triazine framework (CTF) material in removal of organic dyes in water phase

A technology of covalent triazine skeleton and organic dyes, applied in adsorption water/sewage treatment, filter regeneration, filtration and separation, etc., to achieve the effect of simple operation, simple and easy regeneration method, and good adsorption and removal effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] The preparation process of the adsorbent CTF used: synthesized according to the previously reported literature (Angew.Chem.Int.Edit., 2008, 47, 3450-3453). That is, in an inert gas atmosphere, exhaust the gas in the ampoule containing the precursor 1,4-terephthalonitrile and zinc chloride, and seal it. Heating from room temperature to 400°C and keeping it at this temperature for 20 hours, then raising the temperature to 600°C within 30 minutes and keeping it for another 20 hours, grinding the obtained reactant, washing with water to remove zinc chloride, and then using Diluted hydrochloric acid was used to wash away the residual salt, and finally washed again with water and THF to obtain a black powder. The final product was placed in a vacuum oven at 150°C and dried overnight.

[0032] A concise reaction scheme is as follows:

[0033]

Embodiment 2

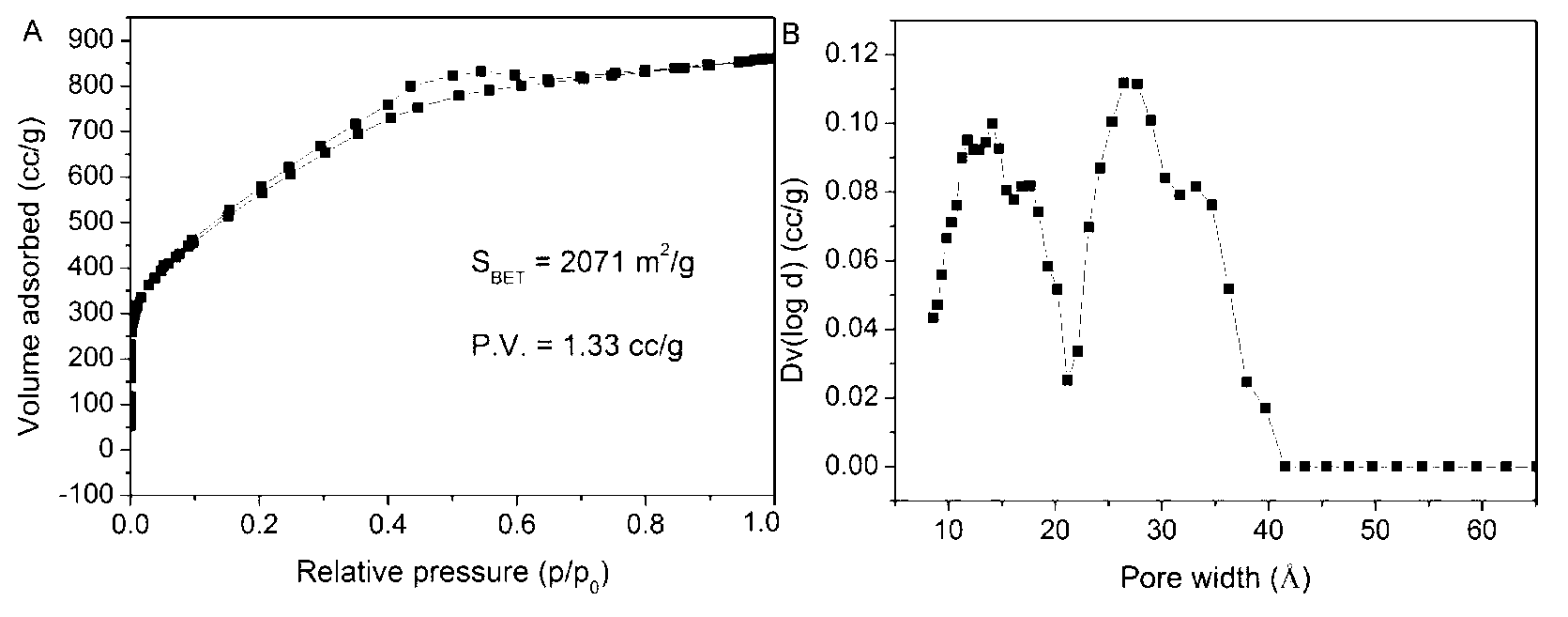

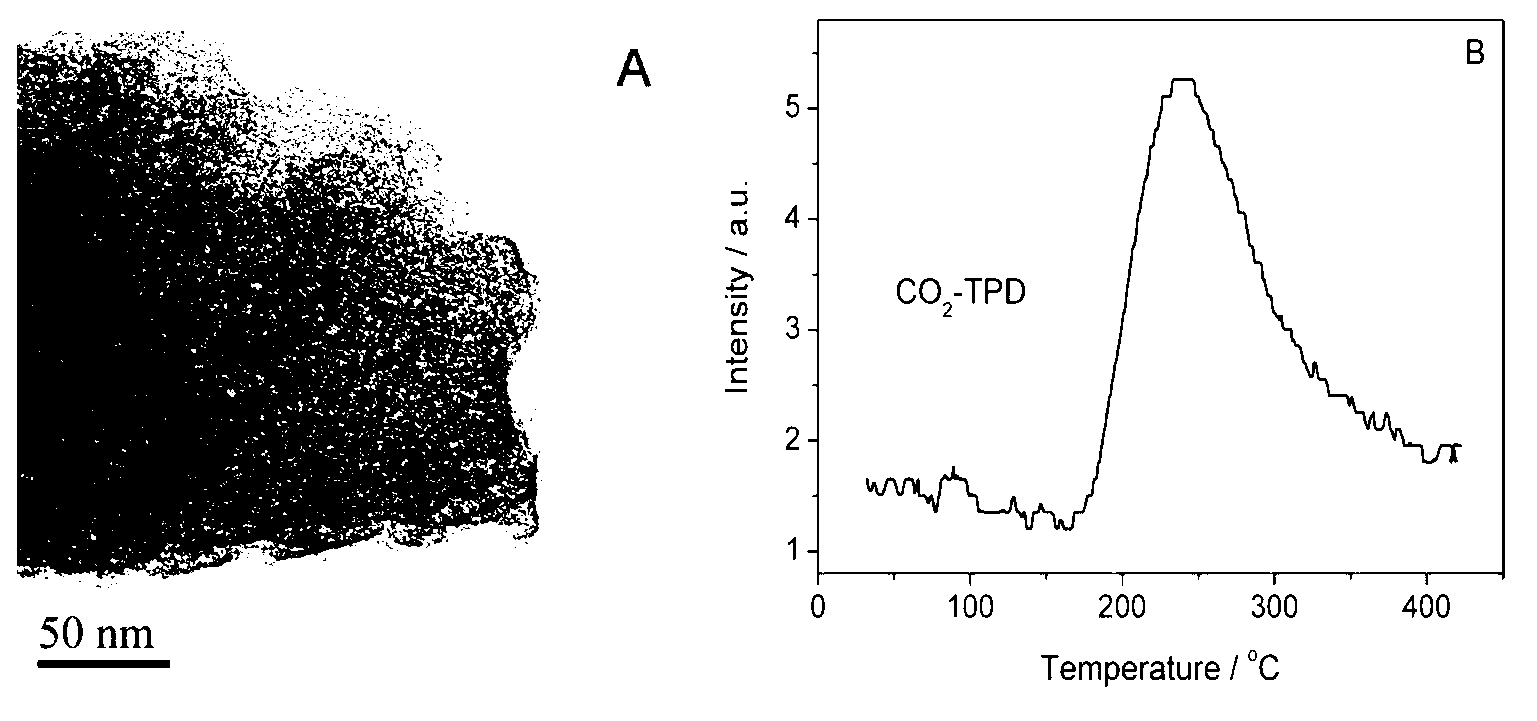

[0035] Carried out nitrogen physical adsorption, transmission electron microscope scanning and CO 2 Characterization of temperature programmed desorption, figure 1 It shows the nitrogen physical adsorption isotherm curve and the corresponding pore size distribution diagram, showing that the CTF material has the characteristics of double pore size distribution, the pore size is concentrated at 1.4 and 2.8nm, and has a high specific surface area (2071m 2 / g) and large pore volume (1.33cm 3 / g), satisfying the general characteristics as an adsorbent, thus we think it will be an adsorbent material that can effectively remove organic dyes in aqueous phase. Transmission electron microscopy results found that CTF looks like a translucent material, indicating that the material has good porosity, see figure 2 a. CO 2 -TPD results show that there is a large desorption peak at 240°C, indicating that CTF has a large number of surface basic sites of moderate strength, see figure 2 b...

Embodiment 3

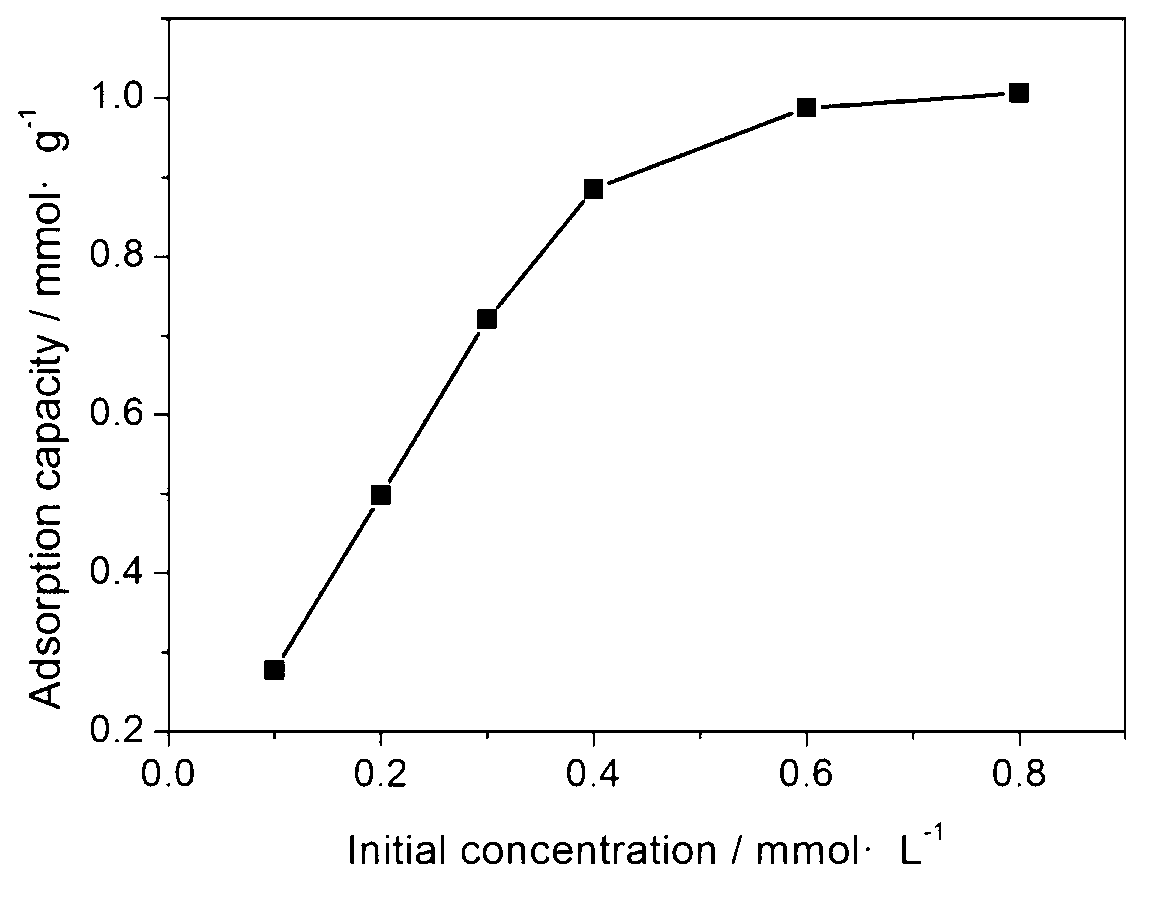

[0037] In order to obtain the adsorption capacity of CTF to rhodamine B, according to the technical scheme (5) in the content of the invention, the adsorption experiment of CTF to different concentrations of rhodamine B was studied, and the results are as follows image 3 Shown: At low concentrations (1 x 10 -4 M), CTF can completely adsorb Rhodamine B in the solution. At this time, CTF is not saturated. As the initial concentration of Rhodamine B increases, the adsorption capacity of CTF also gradually increases and reaches 8×10 -4 At M, it can be considered that the adsorption saturation is basically reached. At this time, the corresponding adsorption amount of 1.006mmol / g is the adsorption capacity of CTF for rhodamine B.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com